What are the gel characteristics of Konjac gum, Xanthan gum and carrageenan blends?

Konjac gum, Xanthan gum, carrageenan

Amorphophallus Konjac.K. Amorphophallus Konjac.k. Amorphophallus gum is an underground tuber of the perennial herb Amorphophallus Konjac.k. Its main component is glucomannan (KGM). Glucose and mannose are present in the hydrolytic solution.

Xanthan gum is a stable extracellular metabolic gum of microorganisms. Glucose, mannose and uronic acid can be obtained after complete hydrolysis.

Carrageenan, also known as carrageenan, deer horn gum, Irish licheneenan, is mainly obtained from the lower flowering plants of Chondrus, Eucheuma, Gigaruna and Hypnea and other varieties of seaweed, its variety, chemical structure is complex.

Colloidal substances are important food additives, however, due to the limited number of food adhesives approved for use as food additives, the development of a new food adhesives is costly, so the combination of adhesives is particularly important.

Many studies have shown that mixing K-carrageenan with locust bean gum can enhance the gel strength. However, locust bean gum used in food industry is mostly imported and expensive. At the same time, people found in the study that Konjac gum and locust bean gum in China have many similar properties, and Konjac gum instead of locust bean gum and K-carrageenan compound, its gel strength is stronger. Considering that konjac gum and xanthan gum also have good compounding effect, this paper selected the gum obtained from the above different grades of organisms, mixed, and achieved better results. The combination of edible glue

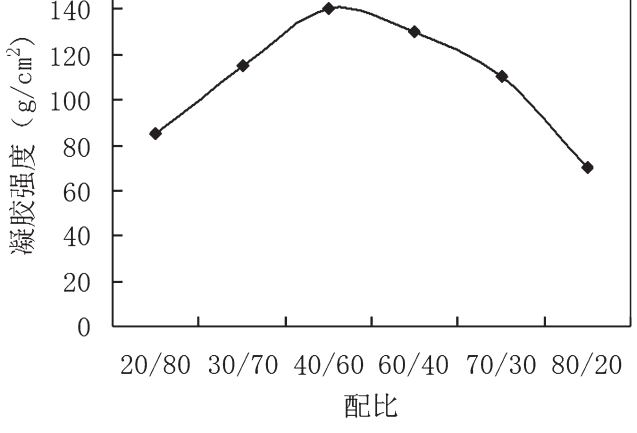

2.1 Ratio effect of konjac gum and carrageenan

As can be seen from Figure 1, as the proportion of KGM increases, the proportion of carrageenan decreases, and when the blending ratio of KGM and carrageenan is 40/60. The gel strength reaches the maximum 140g/cm2. If the blending ratio of the two gels continues to change, the gel strength decreases.

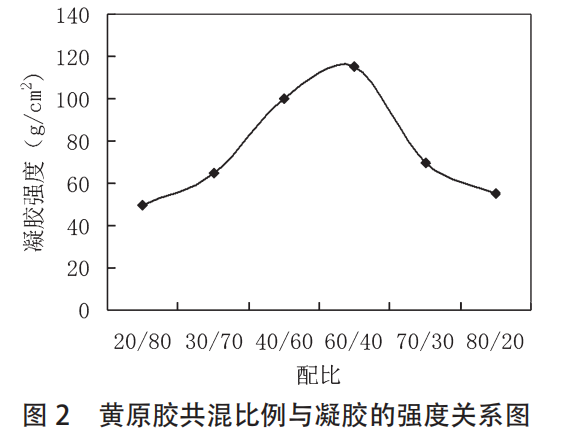

2.2 Ratio effect of Konjac gum and xanthan gum

As can be seen from Figure 2, as the proportion of KGM continues to increase, the proportion of xanthan gum continues to decrease, when the blending ratio of KGM and xanthan gum is 60/40. Gel strength reaches maximum. If the blending ratio of the two gels continues to change, the gel strength decreases.

2.3 Ratio effect of Konjac gum and Xanthan gum According to the binary mixing ratio, the proportion of KGM was initially determined to be 50%, and the proportions of the remaining xanthan gum and carrageenan were 10:40, 15:35, 20:30, 30∶20, 35∶15, 40∶10, respectively.

Results and discussion

Konjac gum and carrageenan have better blended gel properties. When Konjac gum is blended with xanthan gum alone, its gel properties are also improved to a certain extent, but the effect is worse than that of carrageenan. The reason may be that Konjac gum and xanthan gum have similar monomer structure, and their degradation products contain mannose. The ternary blends of Konjac gum, carrageenan and xanthan gum were found to have better synergies. More test parameters and more applications of gels need to be further studied.