Optimization of Paraherquamide A Fermentation Process Using Response Surface Methodology

Parasitic nematode disease is a parasitic disease of livestock and poultry that seriously affects the development of animal husbandry. At present, avernectins are the most widely used antiparasitic drugs in veterinary clinical practice worldwide. However, due to the abuse of this drug, drug-resistant strains have emerged in many areas. In the late 1980s, China introduced and widely used this type of drug, and now domestic sheep gastrointestinal nematodes have developed varying degrees of resistance to avermectin drugs. Startect ® is a new type of sheep oral short acting deworming drug developed by Zoetis, the world’s largest animal health drug and vaccine company, which can effectively prevent and solve livestock and poultry parasitic diseases and their drug resistance problems. The active ingredients of this drug are derquantel (10mg/mL) and avermectin (1mg/mL). The standard dose of Startect ® is 1mL/5kg (liquid volume/sheep body weight), and each 50kg adult sheep requires approximately 0.1g of Dexmedetomidine to be administered once. According to the statistics of the Food and Agriculture Organization of the United Nations (FAO), the world’s sheep inventory has reached 1.2 billion. Therefore, the potential demand for Dequnt is in the hundreds of tons or even higher, and the market demand is huge.

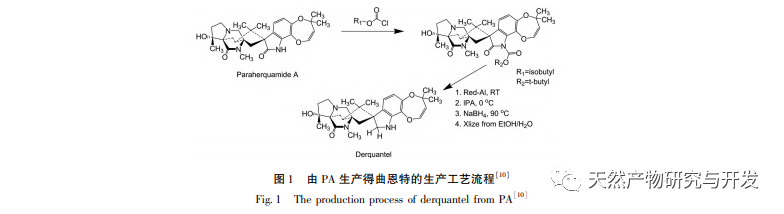

Dextrant is a chemical derivative of the fungal metabolite Paraherquamide A (PA), which is mainly obtained through amide carbonyl reduction and deoxygenation of PA (see Figure 1). Therefore, the industrial raw material supply of Dequnte is mainly affected by PA production. However, the chemical structure of natural products such as Paraherquamide is complex. Although they can be chemically synthesized from industrial raw materials such as isoprene or isoprene epoxides, their chemical reaction steps can reach up to 46 steps, resulting in high costs and extremely low yields (2.5%), making it difficult to produce on an industrial scale. The production of PA through microbial fermentation is currently an effective way to obtain this compound on a large scale. PA was first isolated from the fermentation product of a strain of Penicillium paraherquei, a fungus belonging to the genus Penicillium. However, the potency of PA produced by the wild-type Penicillium was not high, which hindered its further experimental research and industrial application. In the application research of fungal metabolites, the potency level of the target metabolite depends not only on the performance of the strain itself, but more importantly, on optimizing the fermentation and cultivation conditions to fully utilize its production capacity. The response surface methodology is currently widely used for optimizing microbial fermentation culture. This method combines experimental design and mathematical modeling, and has the advantages of fewer experiments, shorter cycles, higher accuracy in obtaining regression equations, better predictive performance, and studying the interaction between several factors.

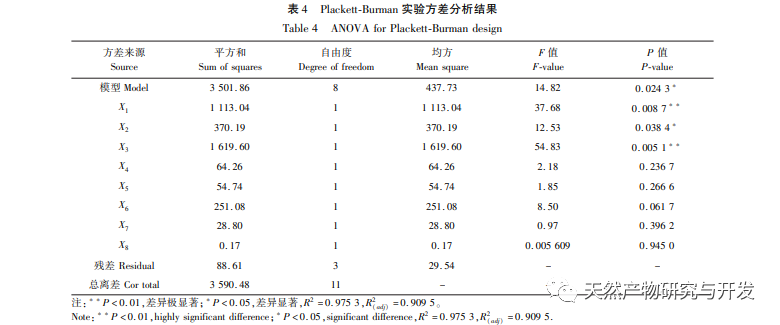

In the preliminary work, our research group discovered a marine derived Penicillium fungus KWF31 with high PA production. The initial exploration showed that its fermentation potency was 55.8 ± 3.7mg/L under the Chatelier medium, which did not meet the requirements of industrial production. The aim of this study is to optimize the fermentation medium of strain KWF31 using response surface methods such as Plackett Burman design, steepest climb design, and Box Behnken design, and establish a high-yield and stable PA production process technology scheme.

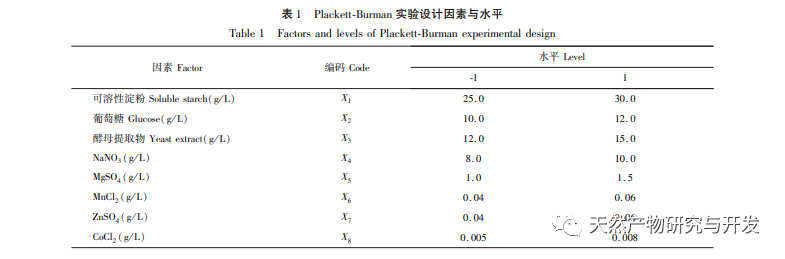

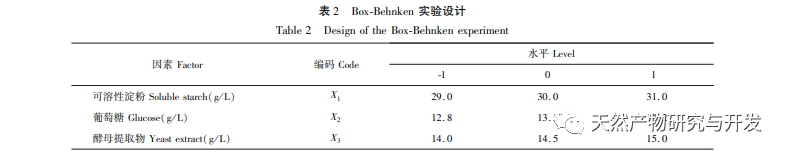

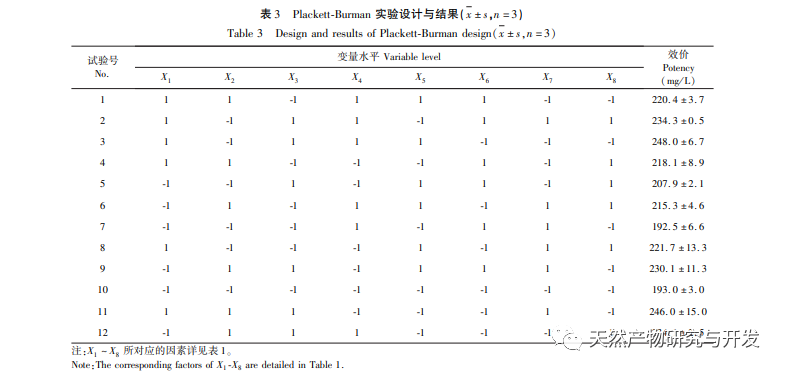

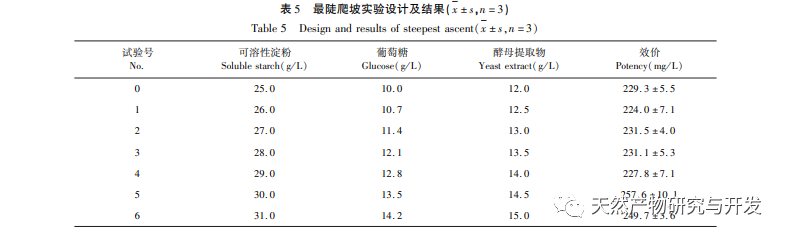

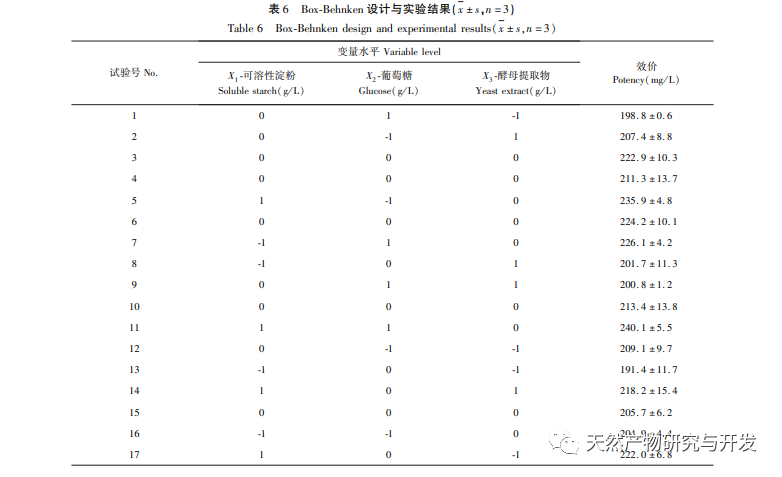

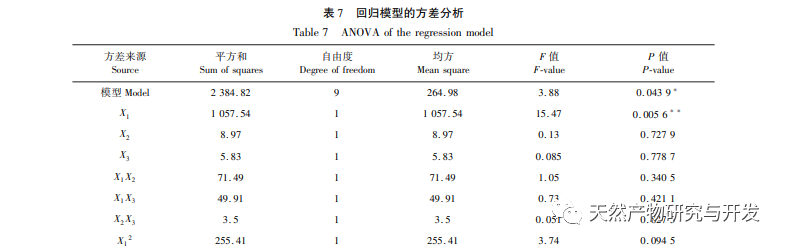

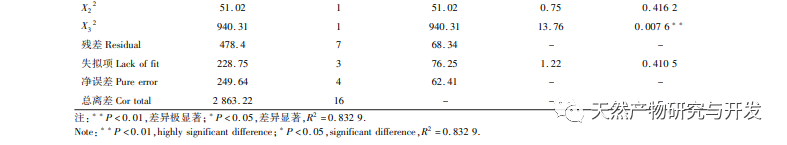

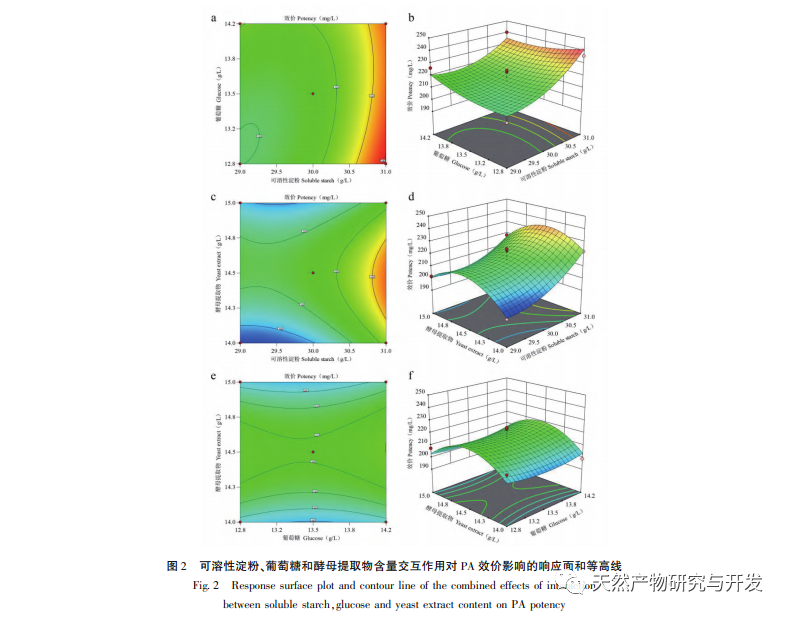

PA is an isopentenyl indole alkaloid with a unique chemical structure and excellent insect resistance activity. It is a raw material for the synthesis of commercial insect resistant agent Dextrant and has high market value and huge market demand. However, the wild-type Penicillium strain has a low yield of PA, with multiple chemical synthesis steps and low yield, making it difficult to meet market demand. This study used Plackett Burman design to screen out three medium components that significantly affect the horizontal fermentation production of PA by wild strain KWF31 in shake flasks from eight factors: soluble starch, glucose, and yeast extract; Their concentrations were gradually optimized using climbing experiments and Box Behnken design. The optimized optimal concentrations are soluble starch 31.0g/L, glucose 1208g/L, and yeast extract 14.5g/L. In this medium, the wild-type strain KWF31 showed a high potency of 243.7 mg/L for PA production during shake flask horizontal fermentation, which was 3.4 times higher than before optimization (55.8 mg/L). The process established in this study for the fermentation production of PA by the marine fungus KWF31 has good reproducibility, stability, and controllability. On this basis, further development of industrialized fermentation processes lays the foundation for the development of new anti nematode pesticides in China, which has important theoretical and practical significance for promoting the healthy development of animal husbandry in China.

PA is an isopentenyl indole alkaloid with a unique chemical structure and excellent insect resistance activity. It is a raw material for the synthesis of commercial insect resistant agent Dextrant and has high market value and huge market demand. However, the wild-type Penicillium strain has a low yield of PA, with multiple chemical synthesis steps and low yield, making it difficult to meet market demand. This study used Plackett Burman design to screen out three medium components that significantly affect the horizontal fermentation production of PA by wild strain KWF31 in shake flasks from eight factors: soluble starch, glucose, and yeast extract; Their concentrations were gradually optimized using climbing experiments and Box Behnken design. The optimized optimal concentrations are soluble starch 31.0g/L, glucose 1208g/L, and yeast extract 14.5g/L. In this medium, the wild-type strain KWF31 showed a high potency of 243.7 mg/L for PA production during shake flask horizontal fermentation, which was 3.4 times higher than before optimization (55.8 mg/L). The process established in this study for the fermentation production of PA by the marine fungus KWF31 has good reproducibility, stability, and controllability. On this basis, further development of industrialized fermentation processes lays the foundation for the development of new anti nematode pesticides in China, which has important theoretical and practical significance for promoting the healthy development of animal husbandry in China.