What is the application of food colloids in vegetable protein meat?

Plant protein meat is a bionic meat product with animal meat fiber structure, texture, color, flavor, texture and appearance prepared by certain technical means using plant protein as the base material. The composition, type of ingredients and moisture content of the plant meat matrix can have a significant impact on the texture and mouthfeel of the final product.

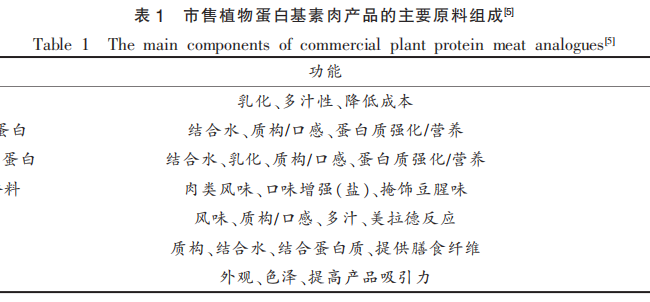

The effect of material properties and composition on the organizing characteristics of extruded products is significant and complex. Commercially available formulations of organized protein-based plant meats consist of six main components (Table 1): water, protein, flavoring agents, fat, binder and coloring agents. Water accounts for 50% to 80% of the total ingredients and serves as a plasticizer and provides juiciness during the processing of plant-based meat products.

Since food colloids such as proteins and polysaccharides play a crucial role in product identification and differentiation, and fat analogs are key factors in improving flavor, texture, mouthfeel and nutritional aspects, this paper focuses on the progress of research on the application of food colloids such as proteins, polysaccharides and fat analogs in plant-based meat.

It mainly includes 3 aspects: 1) the types, functions and formation mechanism of protein fibre structure of high moisture organized protein fibres; 2) the effects of the types, structures and functions of polysaccharides on the macroscopic and microstructures and textures of high-moisture extruded plant meats; and 3) the development of fat mimics based on food colloids and their applications in plant meats. Proteins

Plant proteins are mainly composed of globular proteins, and the forces that maintain their high-level spatial structure are mainly weak interactions such as non-covalent or secondary bonds. Almost all plant proteins can be used as raw materials for the preparation of plant-based artificial meat, e.g., legume proteins, cereal proteins and potato proteins are the bulk raw materials for the production of plant-based meat.

1. Legume proteins Based on a comprehensive analysis of raw material yield, price and functional properties, soybean protein isolate (SPI), soybean protein concentrate (SPC) and pea protein isolate (PPI) are commonly used in commercially available plant-based meat products due to their lower price and better emulsification, gelation, water-holding and fat-binding properties.

Despite the fact that high protein purity is not positively correlated with the texture and appearance of plant meat, SPI is most commonly used in the study of high-moisture extruded plant protein meats by virtue of its protein content of more than 90%, weak soybean odor, and lighter color.SPI formed a fibrous structure that was visible to the naked eye at a moisture content of 50%, and anisotropic structure was confirmed by X-ray scanning. The formation of anisotropic structure was confirmed by X-ray scanning.

Pea protein is the main component in the by-product of pea starch processing into pea vermicelli. Pea protein is the main plant source of branched-chain amino acids (BCAAs), containing up to 18.1%. Branched-chain amino acids make up about one-third of skeletal muscle proteins. Supplementation with branched-chain amino acids can inhibit the degradation of skeletal muscle proteins, relieve delayed-onset muscle soreness after strenuous exercise, and promote muscle recovery.

With low allergenicity, high nutritional value, emulsification and foam stability, pea protein has become a mainstream plant-based meat protein ingredient. However, pea protein has a weak gelation ability, and the prepared plant meat has a soft texture and poor elasticity. In order to improve the gelation characteristics of pea protein, different kinds of salts (NaSCN , NazSO4, CHCOONa, NaCl) are often added to the system to enhance the gel strength by promoting the formation of more hydrogen bonds between pea protein molecules.

In addition, the legume proteins currently used for high humidity extrusion include lupine, fava bean, mung bean, and chickpea. Because mung bean protein has a good gelling ability, help particles combined and enhance the water holding capacity, it is often used and soy protein, pea protein compound to improve the texture of plant meat, enhance chewiness.

2. Cereal protein grain is the most important food crops, commonly used as seeds (rice, barley, oats and corn) and flour (wheat, rye and corn). Wheat protein (WG) is an economically important by-product of the wet processing of wheat flour and consists mainly of wheat alcohol soluble protein and wheat glutenin. Wheat protein has viscoelasticity, bonding ability, dough formation ability and fermentation ability, it is a promising binder material, which can be used as a thickener for meat patties, as a binder for sausage products, and can be bonded to large pieces of foodstuffs to make reconstituted foodstuffs.

Rice protein, according to its solubility and biochemical properties can be divided into four categories: clear protein, globulin, glutenin and alcohol-soluble proteins, of which glutenin also has a subunit connected by disulfide bonds, applied in plant meat with the role of improving texture.

Cereal proteins have a high content of cysteine and methionine, while lysine is the first limiting amino acid. Rice has a high lysine content, much higher than that of wheat protein (2.3 g/16 g N) as well as corn protein (2.5 g/16 g N). Rice protein has a high bioavailability of 77, which makes it a high-quality plant protein, similar to the values of beef (77) and fish (76).

Rice protein is often added to solve the problem of unbalanced amino acid composition of legume proteins. In addition to wheat and rice proteins, there are corn, barley, oat, and sorghum proteins. All of these proteins can be used in the production of organized proteins, however, it is not suitable for mass production considering the economic benefits.

3. Potato and other proteins Although the protein content of potato tubers is not high (2.3%), potato proteins are of high nutritional value, rich in lysine, methionine, threonine and tryptophan, with a bioefficacy of about 80, which is significantly higher than that of the FAO/WHO standard protein.

Potato glycoprotein is the main component of potato protein, with good solubility, emulsification, foaming and gelation. Potato protein in addition to commonly used to supplement the bean protein to improve the texture, but also from rapeseed, cottonseed, peanuts, sunflower seeds, sesame, safflower, flaxseed and other oilseed crops extracted from vegetable proteins used as a raw material for vegetable protein meat. Carbohydrates

Salt-soluble myofibrillar proteins play a dominant role in the formation of texture and water fixation in processed meats. In vegetable protein-based meat products, carbohydrates are often used as binders and structural aids to improve texture, increase the water holding capacity of the meat, and improve product texture. Carbohydrates can be divided into 2 main groups: the first group is polysaccharide and its derivative colloids, and the second group is digestible starch.

1. Polysaccharide colloids and their derivatives Polysaccharide colloids can be extracted from seaweeds (e.g. carrageenan and algin), trees (gum arabic), or produced by microbial fermentation (xanthan gum). Due to its polyol (OH group) structure, it usually carries negatively charged groups (sulfur and carboxyl groups) and is able to strongly bind water through hydrogen bonding and ion-dipole interactions, thus increasing the thickness and consistency of plant meat and reducing cooking losses.

Carrageenan is a class of sulfated anionic polysaccharides derived from red algae. It is classified into 3 main groups based on the number and position of sulfate groups on the galactose/dehydrogalactose chain: k-type, ι-type and λ-type. Among them, k-type-carrageenan contains one sulfate group in the repeating unit of each disaccharide, and ι-type and λ-type contain two and three sulfate groups, respectively.

Under certain conditions, k-type carrageenan and ι-type carrageenan can form thermoreversible gels due to heating-induced intramolecular loop closure, and therefore play an important role in the structural control of extruded substances.

In addition to the type of carrageenan, the amount of carrageenan added also has an important effect on the structure of organized proteins. At lower carrageenan addition levels (less than 1%), the degree of organization of high-moisture extruded peanut proteins showed a tendency of increasing and then decreasing with the increase of carrageenan addition, and the fibrous structure was the most significant at the addition level of 0.1%, while the hardness and chewiness decreased.

At moderate additions (1%-3%), carrageenan reduced the hardness, cohesion and viscosity of SPI extrudates to some extent, with no significant effect on elasticity. At higher addition levels (3%~7%), ι-type carrageenan (6%) formed a more compact network structure in SPC extrudates, increased fibrillation, and improved rehydration and digestibility, where disulfide and hydrogen bonds were the main forces maintaining the organized structure.

Many plant meat products contain methylcellulose, which is a modified dietary fiber that has an emulsification-enhancing effect in animal meat, and the addition of an appropriate amount of methylcellulose to plant meat can act as a binder.

From a nutritional point of view, methylcellulose produces a viscous solution in the gastrointestinal tract that, like other dietary fibers, has a role in glucose metabolism. The addition of guar gum further improves the hardness, elasticity, cohesion and viscosity of SPI extruded samples. Pectin is distributed in the continuous phase of SPI, and pectin fiber length increases and anisotropy increases when pectin concentration and shear temperature increase.

2. Starch starch as a class of polymer carbohydrates, can be divided into straight chain starch and branched chain starch, in contact with water by pasting and aging can form a gel. Due to the advantages of low price, renewable and fast biodegradation, it is often widely used as a thickener and stabilizer in meat processing.

Plant meat products, in addition to protein, starch is the main component, by combining with water and fixing fat, improve rheology, texture and consistency, reduce water analysis, and emulsification of oil.

3. Fat simulants Animal fats are a major factor in meat flavor, texture, juiciness and mouthfeel. Natural fats are mixtures of mixed glycerides, mostly saturated fatty acids. The melting point of fat increases with the growth of the carbon chain of fatty acids in it and the degree of saturation. Pork fat has a melting point of about 28 to 48°C, and beef fat has a melting point of 40 to 50°C.

Everyday see the animal fat are solid, while the plant fat is mostly unsaturated fatty acids, lower boiling point, liquid at room temperature. In order to simulate animal fats, coconut oil (24 ℃) and palm oil (up to 58 ℃), which have high melting points, are mainly used as vegetable fats.

To develop textures and flavors similar to animal fats, solid fats extracted from tropical fruits, such as coconut and cacao nibs, are blended with liquid oils containing more unsaturated fatty acids, such as sunflower and canola oils.

To make plant-based burgers and sausages look as marbled as regular ground beef and pork sausage patties, the mixture of saturated and unsaturated oils is churned into small balls of white fat. For nutrition and flavor, sesame oil and avocado oil are added.