How to improve the crispness of fried food?

Fried food is one of China’s traditional food, which has a crisp sense of food, tangy aroma and golden color, people, deeply loved by consumers. Many fried foods usually need to be coated with powder to ensure the quality of products in the frying process, such as fried chicken, fried fish, fried shrimp and so on.

Coating powder is a pre-prepared powder, flour or starch as the main material, and add thickening agent, seasoning, coloring agent and other additives mixed, its main role is to improve the application effect of the product. The traditional use of powder is a single flour as the main raw material, but because the flour in the frying oil absorption is large, and the shelf life is not long, long time will make the product softening phenomenon, reduce the taste of the product.

Adding modified starch to coating powder can greatly improve the appearance, color and taste of the product, and increase the yield of the product [1]. Among them, denatured starch can be added to the coating powder, and cold water can be used for pulping, which can also increase the proportion of gouache in the preparation of the slurry, increase the stability and fluidity of the slurry, enhance the product’s tender and juice retention, and reduce the amount of thickener used [2]. The addition of modified starch to the pre-prepared powder can increase the bonding force between the ingredients and the coating, so that it is not easy to peel, but also enhance the water retention. The addition of modified starch [3-4] to the coating powder can make the product have attractive color and good taste.

According to the different raw materials and denaturation methods, there are many kinds of denaturated starch. The application effect of oxidized starch and oxidized compound denaturated starch mixed with colloid in frying powder was studied, which provided theoretical support for the application of denaturated starch.

Materials and methods

1.1 Materials Flour, carboxymethyl cellulose (CMC), xanthan gum, gelatin (food grade), are for sale in the market; Modified starch: cassava acetate starch, cassava oxidized starch, cassava oxidized hydroxypropyl starch, Gansu Fengshou Agricultural Technology Co., LTD. White sugar, vegetable oil, salt, ginger powder, pepper powder, chicken breast meat, potato starch, corn starch, etc.

1.2 Instruments and equipment Induction cooker, range hood, spatula, wok, etc.

1.3 Process Process Chicken breast (frozen) → thawing → (adding spices and ice water) pickling → sizing → Wrapping → frying → quick-freezing → packaging → storage.

1.4 Test Methods 1.4.1 Raw material treatment (1) Thawing. Remove the outer packing box and inner packing plastic bag from the chicken breast meat that has passed the veterinary inspection, and thaw it naturally on the stainless steel cutting board in the thawing room until the center temperature of the meat is -2℃.

(2) pickling. Dissolve potato starch, sugar, salt, pepper and ginger in water. Pour into a beaker containing chicken. Stir well. Standing in the cold room at 0~4℃ for 12h is conducive to the full absorption of brine by chicken.

(3) Colloidal solution. Xanthan gum, gelatin and CMC were prepared into colloidal solution by adding water in a certain proportion and standing for 12h to make the colloid fully absorb water and dissolve before use [5].

(4) Preparation of slurry. Mix about 80% of flour and corn starch with about 20% of denatured starch evenly, and then add the mixed colloidal solution and a certain amount of water, so that the ratio of the mixed powder and water is 1:1.5~1:2.0, stir evenly for use.

(5) Sizing. Put the cut chicken pieces into the grout, slowly stir for 3min, so that the grout is evenly attached to the chicken pieces.

(6) dandruff. Put the mixed coating powder on the stainless steel plate, put the starched small chicken breast into the coating powder, turn over so that the coating powder is evenly attached to the surface of the meat, into a thin willow leaf shape, and finally put in the plastic net basket, gently shake to shake off the surface of the powder.

(7) Deep fry. First, add a certain amount of shortening or palm oil in the frying machine, preheat to 185℃, so that the wrapped chicken pieces successively through the oil layer, frying time 25s, the color is light yellow after frying, take out the oil.

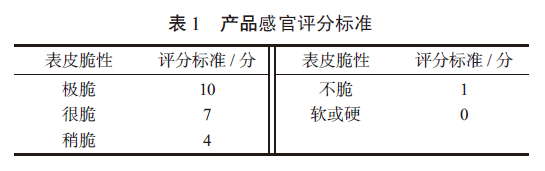

1.4.2 Product Evaluation method 10 people were randomly selected to participate in sensory evaluation of products, and the average score was obtained. The product sensory rating standards are shown in Table 1.

Results and analysis

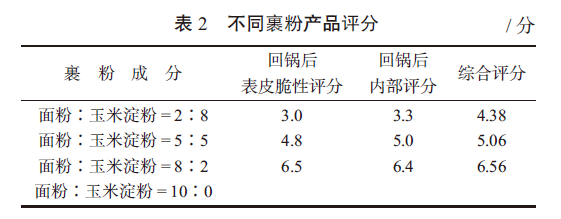

2.1 Determine the ratio of flour and cornstarch The flour and cornstarch were mixed according to 2:8, 5:5, 2:8, and then the flour coating and frying test was carried out, and then different flour coating pastes were used to make fried food. After frying, the products were frozen and stored. After 10d, the products were returned to the pot for taste, and the skin and stuffing were scored respectively. The scores of different coating products are shown in Table 2.

From Table 2, it can be seen that among the three kinds of flour coating, the product made with the ratio of flour to corn starch 8:2 is the best brittle and has the highest comprehensive score. This is because the protein content in flour is high, the wheat starch content is low, and the wheat starch particles are small, the gelatinization temperature is high, adding a certain amount of corn starch in flour can improve the crispness of the product, so the ratio of flour and corn starch added is 8:2.

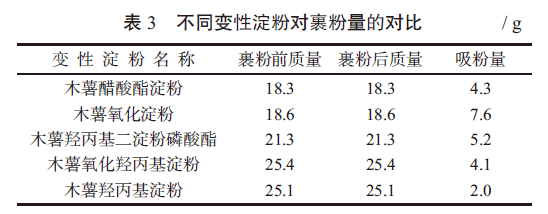

The ratio of flour and corn starch is 8:2, and 20% of different modified starch is added. The effects of several modified starch on the coating amount and application effect after frying are observed. The comparison of coating amount of different modified starch is shown in Table 3.

As can be seen from Table 3, cassava oxidized starch has the largest amount of powder absorption, while cassava hydroxypropyl starch has the least amount of powder absorption. This is because after the starch is oxidized, the starch particles become smaller, have good absorption [6], and can quickly interpenetrate with the protein in flour, so the cassava oxidized starch has the largest amount of powder absorption.

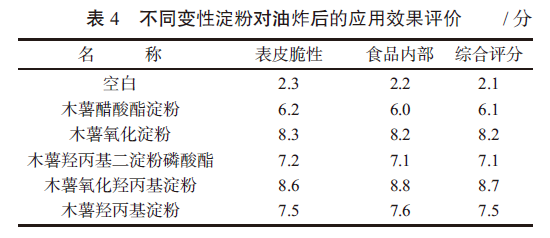

2.3 Evaluation of the application effect of different modified starches on frying The evaluation of the application effect of different modified starches on frying is shown in Table 4.

As can be seen from Table 4, the application effect of cassava oxidized hydroxypropyl starch and cassava oxidized starch is better, which is because the surface of cassava oxidized hydroxypropyl starch and cassava oxidized starch are coated with a higher amount of powder, and the film formation of starch after oxidized treatment is higher. After the product is fried at high temperature, starch curing can form a dense protective film on the surface of the product [7]. It can effectively prevent the effect of high temperature on the inside of the product, but also prevent the internal water of the food from losing more water due to high temperature frying, and keep the food fresh and tender and the surface crisp. Therefore, cassava oxidized hydroxypropyl starch was used as modified starch in powder coating.

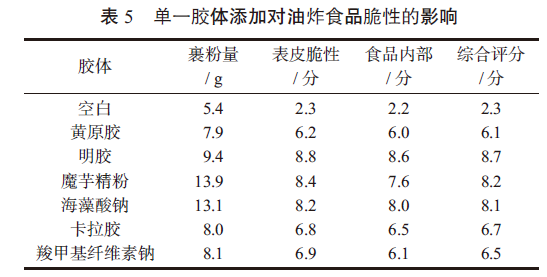

2.4 The effect of single colloid addition on the brittle-iness of fried food The same amount of xanthan gum, carrageenan, sodium alginate, konjac powder, sodium carboxymethyl cellulose (CMC) and gelatin are added to the coating powder formula (the ratio of 80% flour and corn starch is 8:2, and the addition amount is 20% cassava oxypropyl starch) to make fried food. The fried food was frozen and stored, and reset in the microwave oven after 10 days to evaluate the fried food. The effect of single colloid addition on the brittleness of fried food is shown in Table 5.

As can be seen from Table 5, sodium alginate, gelatin and konjac powder have better effects than other colloids. Adding appropriate amount of gelatin and konjac powder to the coating powder can significantly improve the brittleness of the product, and adding appropriate amount of sodium carboxymethyl cellulose can significantly fluff the surface of the product and give the product a crisp taste, because the main component of gelatin is protein. Protein curing modification, increased brittleness.

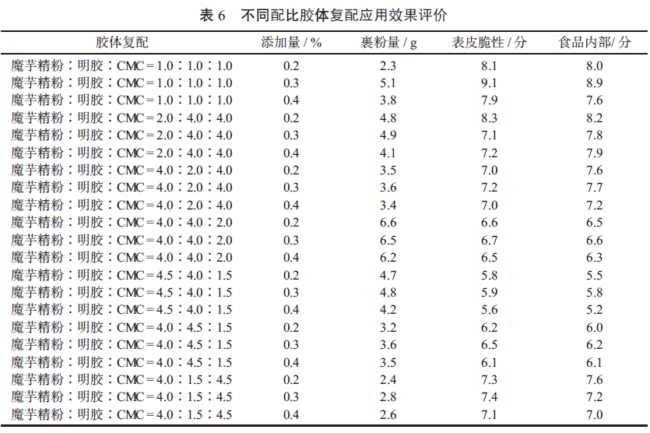

2.5 Evaluation of Application Effect of Coating main material and colloid On the basis of the above tests, three kinds of coating main material with the addition amount of 80% (the ratio of flour to corn flour is 8:2) and cassava oxypropyl starch with the addition amount of 20%, and the additives are CMC, gelatin and konjac powder, were combined to study the application effect of different ratios on coating products. The application effect evaluation of colloid compounding with different proportions is shown in Table 6.

By adding a certain amount of konjac powder, gelatin and CMC in the coating powder, and adding 0.3% according to 1:1:1 ratio, the application effect is better. This is because after the compound addition of gelatin, konjac powder and CMC, Konjac powder and gelatin can significantly improve the brittleness of the product, CMC can significantly fluffy the surface of the product [8], giving the product a crisp taste, and its compound addition can play a synergistic effect. conclusion

The crispness of fried food is mainly determined by the crunchy taste after the surface is coated with powder and fried, and the filling is tender and juicy, and the skin is crisp, that is, the internal moisture content is high, and the skin moisture content is low and not hard.

On the basis of studying the main ingredients of frying powder, a compound modifier which can significantly improve the quality of fried food is obtained by adding a certain amount of modified starch and compounding colloid. The formula is 80% flour and corn starch (the ratio of the two is 8:2, the addition amount of 20% cassava oxypropyl starch). The ratio of 0.3% Konjac powder, gelatin and CMC is 1:1:1. The composite coating powder is easy to use and stable in quality. The color and taste of the food produced by using the compound powder were improved.