What are the common process problems and solutions for suspensions?

As a unique beverage variety, suspended fruit drink has gone through more than 20 years since its introduction in the 1980s. Suspended fruit drinks have many excellent sensory effects and characteristics, such as a strong sense of reality, unique appearance, rich in nutrients, easy to drink, and so on, and are therefore favored by the majority of consumers. “Gel to suspend” principle of discovery, not only for the fruit particles suspended phenomenon to make a reasonable explanation, but also for the suspension of drinks in the suspension of the choice of suspending agent pointed out the direction: theoretically, all can produce gel monomer or composite gel can be used as a suspending agent. And will only produce viscosity will not form a gel colloid can not become a separate suspending agent. However, in practice, the real colloid can be used as a suspending agent in the production of applications, but also must have the following conditions: First, in line with the safety requirements of food additives; secondly, has a good flavor release properties, excellent taste; thirdly, has a superior resistance to acid pyrolysis; fourthly, anti-dissolution of water performance; fifthly, has a high temperature point of the gel to facilitate the process; sixthly, the amount of provincial. It has better economic performance.

The properties and applications of several commonly used suspending agents I. Agar Agar was first reported to be used as a suspending agent for suspended fruit drinks. Zhou Ying [2] first introduced the use of agar in the production of citrus fruit suspension drinks. Fang Xiugui et al [16], through the experiments on the suspending effect of pectin, gelatin, agar, gellan gum, sodium alginate, carboxymethyl cellulose (CMC) and other colloids on the suspension effect of citrus juice cells, agar is considered to be the most suitable suspending agent, which is used at a concentration of 0.18% to 0.20%, and in the presence of the appropriate concentration of gellan gum, the suspending effect is even better. Li Zhengming et al [17] also studied the use of agar in citrus juice cell suspension beverages and concluded that the combination of agar plus citrate achieved satisfactory results. Peng Jazhe [18] on agar for citrus juice cell suspension experiments of the best results: agar concentration of 0.25%, beverage pH adjustment at 3.6 to 4.0, the dosage should not be heated too long after the heating time.

Zhu Mouhan et al [19] concluded that agar is the strongest gelling agent among the thickeners currently used in production, and even at a concentration of 0.04%, the gelling effect was clearly present, and the beverage had good transparency and smooth taste. Hu et al [1] used agar in the suspension drink of Mingleberry and pointed out that the main factors affecting the suspension effect of agar are concentration, temperature, pH and electrolytes. High temperatures and long duration of high temperatures and high acidity of the solution can cause degradation and failure of agar. The gel strength and viscosity of agar are small in low pH solutions, and increase with the increase of pH, with the maximum viscosity of the solution at pH 6-11. Agar solution gel strength and viscosity with the increase of high temperature duration and decrease, in the high temperature duration of more than 5h, the solution viscosity is very small, can not form a gel. Therefore, the strict control of process temperature and high temperature duration, the selection of suitable acidifier and pH are the key to the success or failure of agar suspension. At the same time, the addition of CMC will also have a greater impact on the gel strength and fluidity of agar, with agar-CMC as the main suspending agent of the beverage, the fluidity and stability of the solution is relatively good, transparent and not easy to precipitate gel, showing a better combination of synergistic properties. Numerous studies have also demonstrated that agar-CMC is an excellent suspending agent combination, resulting in clear and transparent products with good stability [20-24]. Dong Wenming et al [25] used agar compounded with Dianthus saponaria polysaccharide gum to produce a satisfactory aloe vera suspension drink with a suspension formulation of 0.05% agar, 0.03% Dianthus saponaria polysaccharide gum and 0.03% potassium chloride. Wang Yanzhe et al [26] used agar 0.20%, CMC 0.20%, gelatin 0.10% suspension formulation of chrysanthemum petals containing 7% of the beverage had good suspension stabilization. Second, carrageenan Hu Guohua et al [1] studied the suspension effect of carrageenan: carrageenan -K+, carrageenan – locust bean gum -K+, carrageenan – konjac gum -K+ compound suspension agent suspension effect is the most desirable, the latter two showed good combination of synergistic, in a certain range of concentrations of κ-carrageenan and konjac gum and locust bean gum, respectively, when compounded, their gel strength will be significantly increased. ι-carrageenan also has a better suspension effect on the beverage containing 7% of chrysanthemum petals. carrageenan also has a better suspending effect, but its current market price is high, and its application as a suspending agent will be limited. κ-carrageenan as the suspending agent main agent of the Minglezi beverage in the addition of appropriate concentration of K + and other colloids can show good suspension effect, its main disadvantage is not too acid and high temperature resistance, to a certain extent, affecting the suspension stability of the beverage, but is still a more ideal Minglezi beverage suspending agent.

Carrageenan in the suspension of drinks in the amount of 0.1% to 0.4%, K + for 0.2%, Ca2 + for 0.2%. Third, sodium alginate Xiang Yunfeng et al [35] used 0.25% sodium alginate combined with 0.02% calcium chloride to produce a qualified suspended fruit capsule drink. Ai Zhilu et al [36] that the simple use of sodium alginate on the suspension of juice cell stabilization is less than ideal, the use of a mixture of several colloids, such as sodium alginate and carboxymethylcellulose or gelatin mixing effect is better. Fourth, xanthan gum – mannose xanthan gum has a significant feature is its role in promoting the same with mannose, such as locust bean gum, guar gum and so on. When xanthan gum is mixed with mannans, the viscosity of the mixture increases significantly compared to either of them alone [38]. This property makes the complexes of xanthan gum and mannan to be used as suspending agents for fruity beverages.

The xanthan gum and mannose co-promotion has been widely used in the suspension of beverages in two combinations: xanthan gum – konjac gum and xanthan gum – locust bean gum. (A) xanthan gum – konjac gum konjac gum (konjac gum) is the main component of glucomannan, molecular formula for [C6H10O5]n, by D-glucose and D-mannose by 1:1.6 molar ratio to β-1,4 glycosidic bonds connected to the heteropolysaccharide. Xanthan gum and konjac gum are both non-gelatinizing polysaccharides, but mixing the two in a certain ratio can appear synergistic effect to obtain gel, when the mass ratio of xanthan gum to konjac gum is 7:3, and the total content of 1.0%, the synergistic effect reaches the maximum value. Mixed polysaccharide gelation ability is not only related to the mixing ratio, but also related to the salt ion concentration in the beverage system, and the gel strength is maximum when the salt ion concentration is 0.2 mol/L [39-40]. Dong Wenming et al [41] used sweet corn as raw material, with a variety of suspending agent synthesis to study the stability of suspension beverage, the results show that the composite suspending agent of xanthan gum, konjac gum, cyclodextrin is the best, and its optimal dosage of 0.04%, 0.02%, 0.02%, respectively. Can maximize the stability of sweet corn grain spoon, to solve the product in the sales storage process of the particles of the phenomenon of sinking. (ii) Xanthan gum – locust bean gum locust bean gum (locust bean gum) is produced in the Mediterranean region of the acacia tree seeds processed plant seed gum, is a kind of galactose and mannose residues as the structural unit of the polysaccharide compounds, the monomer will not gel. According to Fan Jianping et al [42], xanthan gum and locust bean gum form a gel when the mixture content reaches 0.5% to 0.6%. When the ratio of locust bean gum to xanthan gum was 2:8, the viscosity of the mixture was the highest and its synergism was the best. When the content of the mixture reaches 1%, the viscosity of the mixed solution of locust bean gum and xanthan gum is about 150 times of the viscosity of the single solution of locust bean gum and about 3 times of the viscosity of the single solution of xanthan gum. The viscosity of the mixed solution increases with the increase of the content, when the content is less than 0.3%, the increase is small; when the content is higher, there is a large increase; when the content reaches 1%, the viscosity is 4370 mPa-s. According to Guo Shoujun et al. [43], the conclusion of the study shows that locust bean gum and xanthan gum have a strong synergistic thickening, the viscosity of the compounded gum of locust bean gum and xanthan gum rises with the increase of the content of the colloid. The viscosity of locust bean gum and xanthan gum compounding gum increases with the increase of colloid content; the compounding gum is a “non-Newtonian fluid”, the viscosity of the solution decreases with the increase of shear force; heating can make the viscosity of the compounding gum have a relatively large increase, in which heating for 60min can make the viscosity of the compounding gum tends to be the maximum, and the viscosity of the compounding gum decreases when heated for more than 90min; the viscosity of the compounding gum is affected by pH, which has a certain effect on the viscosity of the compounding gum, in which the viscosity is reduced under alkaline conditions. pH has some influence on the viscosity of the compound glue, in which the viscosity decreases more under alkaline conditions; freeze-thawing changes make the viscosity of locust bean gum and xanthan gum compound glue increase more substantially. Lin Meijuan et al [44] used colloids on the suspension stability of glutinous corn juice, pointed out that when the xanthan gum and locust bean gum mass ratio of 1:4, the beverage sedimentation rate reaches the lowest value, the suspension stability of the best. Si Weili et al [45] studied the effect of konjac gum, locust bean gum and xanthan gum on the stability of suspended fruit juice drinks, the results show that when the konjac gum, locust bean gum and xanthan gum to 3:2:2 ratio of the compound, the amount of 0.06%, the stability of suspended fruit juice drinks is the best, and the viscosity of the moderate, no obvious gel phenomenon. Si Wei Li et al [46] also studied the konjac gum, locust bean gum and xanthan gum compounding and various phosphate class on the stability of suspended fruit sour milk drinks, the study concluded that when the konjac gum, locust bean gum and xanthan gum to the mass ratio of 4:1:2 proportion of the compounding, and the amount of its addition of 0.06%, the system is better suspended; add the total amount of beverage 0.08% of sodium hexametaphosphate, the best system of suspension. V. Low ester pectin (pectin) is a kind of plant gum extracted from citrus fruit peel, it is a high molecular polysaccharide with polygalacturonic acid as the basic skeleton, according to the different degrees of esterification of carboxylic groups on the galacturonic acid of the molecule, it is divided into high ester (HMP) pectin (degree of esterification > 50%) and low ester (LMP) pectin (degree of esterification <50%). HMP pectin relies on hydrogen bonding with sugars and acids to form gels, and requires a higher sugar concentration, making it difficult to use in suspension drinks. LMP pectin, on the other hand, relies on free carboxyl groups to form ionic bonded gels with multivalent cations, and thus can form gels under low or no sugar conditions with only a certain concentration of cations and a certain temperature condition. LMP pectin is an acid-stable polysaccharide with maximum gel strength and viscosity at pH around 3.1. Therefore, when using LM pectin as a stabilizer, the pH should be lowered as much as possible without affecting the taste of the suspended beverage [1]. The advantage of LMP pectin for suspension drinks is that it has a bright and smooth taste, and at the same time, it is acid-resistant and suitable for use in acidic beverages [47], but the disadvantage is that it has a large amount of additives, and the price is on the high side. VI, Gellan gum Gellan gum polysaccharide main chain structure is a linear tetrasaccharide repeating unit, by β-D-glucose, β-D-glucuronic acid and α-L-rhamnose as a repeating unit to 2:1:1 molar ratio polymerization of long-chain molecules; the relative molecular mass of about 0.5×106 Dalton. The difference between high acyl gellan gums and low acyl gellan gums is that high acyl gellan gums have a glycerol ester group at the C-3 position of the first glucose group and an acetyl group at the C-6 position, in which the glucuronic acid can be neutralized by K+, Ca2+, Na+, and Mg2+ to form mixed salts. Treatment of high acyl gellan gums with a pH 10 alkali solution results in low acyl gellan gums, which form firm and brittle gels similar to agar [50]. (I) Low acyl gellan gum Low acyl gellan gum relies on its free radicals and divalent metal ions to form a gel, and the appropriate amount of Ca2+, Mg2+ and other ions combined to form a three-dimensional network structure, not only has a good supporting force, but also has a pseudo-plasticity and low viscosity, so that the beverage maintains good fluidity and suspension ability, and it is also very stable under acidic conditions, so it is very good in the suspension of fruit beverages. Value. Zhu Shubin et al [51] prepared suspension solutions with oligoacylcellulose, calcium carbonate, sodium polyphosphate and citric acid as single factors, respectively. Through orthogonal tests, the optimal formulation of suspension system prepared with oligoacylcellulose was obtained: oligoacylcellulose 0.018%, calcium carbonate 0.04%, sodium polyphosphate 0.02% and citric acid 0.2%. The suspension system was transparent, and the fruit particles could remain in uniform suspension for 90d. Zhong Fang et al [8] and other research that in rheology, the content of 0.1% to 0.4% of the gellan gum sol showed typical yield pseudoplastic characteristics. The yield stress of 0.1% gellan gum sol was 0.405 Pa, which was higher than the shear stress formed by the sinking of orange sand sacs under gravity. Therefore, gellan gum has the potential to be used as a suspension stabilizer in fruit suspension beverages.

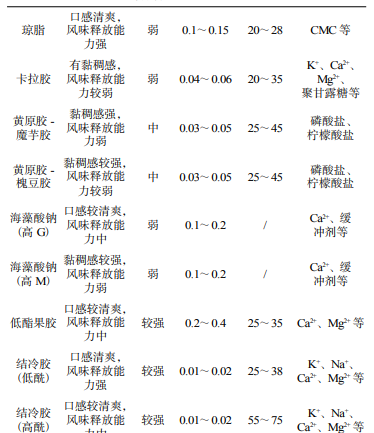

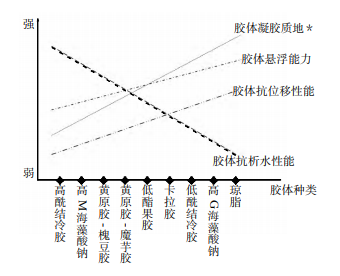

The results of the accelerated storage experiments showed that the best suspension effect of orange sand sacs was achieved when the content of gellan gum was 0.08% and the Ca2+ ion content was 160 μg/g. On this basis, the combination of gellan gum and xanthan gum, with the gel network structure formed by gellan gum and the increase of continuous phase viscosity of xanthan gum under the action of shear, the sinking distance of the sand capsule formed by the orange sand capsule suspension in the accelerated experiments of 90d was less than 1.5cm, and the use of the combination of gellan gum was also conducive to the preservation of orange sand capsule flavor, and the retention of limonene was 28.7% in the accelerated storage experiment after 25d. The retention rate of limonene was 28.7% after 25d of accelerated storage, while the retention rate of control samples without gum was only 0.08%. Wang Xiumei et al [52] concluded that pear particles in the diameter of 3mm, 0.025% of the gelatin can play a better suspension effect, shelf life of up to one year. (ii) High acyl gellan gum High acyl gellan gum gel is soft and elastic, and its gel texture is adapted to the needs of many foods. In the suspension of dairy products, the rheology of high acyl gellan gum in low concentration can play a good role in suspension, high acyl gellan gum is widely used in the suspension of dairy products such as fruit pulp, cocoa powder. The advantages of high acyl gellan gum in yogurt are as follows: it is soluble with casein and will not form wall phenomenon like low acyl gellan gum; it has the characteristics of low dosage and good structural recovery. In fiber-containing juice and soy beverages, high acyl gellan gums can also be well suspended without precipitation [53]. Peracyl gellan gums form soft, elastic gels at about 72 ℃ without temperature lag [54]. Due to the high acyl gellan gum with the dosage of provincial, high gel temperature point, anti-water precipitation, no wall, etc., is now widely used in the “fruit milk” suspension drinks. VII. Comparison of the basic properties of several commonly used suspending agents Through the above description, the main properties of several colloids suitable for suspending beverages are summarized in Table 1 and Figure 2. Table 1 Comparison of the suspension properties of several colloids [57].

Suspension of drinks in the production of common process problems and solutions I. Suspension of acid-heat degradation of suspending agent acid-heat degradation of suspending agent is the key factor affecting the stability of suspension type fruit drinks. Acid-heat conditions can exacerbate the decomposition of colloid failure, the most obvious agar, carrageenan, mannan type, pectin and gelatin acid heat resistance is slightly stronger. Decomposition of colloids, will seriously affect the suspension effect.

In production practice, if the ingredients in the process of colloid heating time is too long, plus acid time is too early, or due to the storage drum capacity is too large, resulting in too long a period of time for the storage of hot materials, will result in levitation difficulties, or the same batch of products in the beginning of the filling product and the end of the product quality of the filling product quality is not consistent situation.

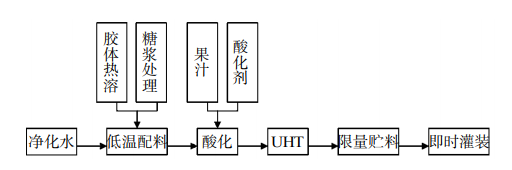

In order to solve this problem, in the production of hot soluble, cold dosage, ultra-high temperature instantaneous sterilization, limited storage of materials, time-limited filling process (Figure 3). With this process to produce suspension type fruit drink, can significantly reduce the use of suspending agent, and make the same batch of product quality to maintain consistency [14].

Fig. 3 Rational process flow of fruit grain suspension beverage [57].

Second, precipitation of water suspension type fruit drinks often appear a product defect is precipitation phenomenon, that is, in the upper part of the drink appeared a section of neither suspending agent, and does not contain fruit transparent layer, and the lower part of the beverage body to form a clear boundary, extremely unsightly, easy to be mistaken by consumers that the beverage spoilage. Due to the use of different suspending agents, precipitation phenomenon can be divided into two reasons.

First, the use of agar and other rigid colloids as a suspending agent, if the suspension of the gel temperature point near the mechanical vibration, such as the production process of cooling while shaking and other operations will cause damage to the gel state of the colloid, the formation of incomplete gel, precipitation of part of the free water, and flocculent colloidal condensate. Therefore, when making fruit drinks with such colloids, it is strictly prohibited to be subjected to mechanical vibration near the gelation point. Only after the complete formation of the gel, can be processed evenly, and at the same time, even when the grain is too much violent shaking, will also make the gel damage, resulting in colloidal precipitation phenomenon.

Secondly, xanthan gum – mannose colloid as a suspending agent, its gelation is mainly based on two kinds of colloid by physical embedding and hydrogen bonding and formation, if the formation of gel by a little strong mechanical vibration, it is easy to make the hydrogen bonding was destroyed, so that the gel phenomenon partially or completely disappeared, resulting in dehydration or sedimentation, so this kind of colloid should be in the initial period of gelation (45 ℃) homogenization, at this time, a little bit of shaking, can achieve the effect of homogenization, without causing water precipitation of colloid. At this time, a little shaking can achieve the effect of homogenization, which will not cause the destruction of hydrogen bonds [14]. Third, the fruit particles of the transportation settlement (oscillation displacement) suspension type fruit drinks in the production and marketing process, there are often such problems: that is, the production of good suspension of the product, after a long period of transportation to reach the point of sale, found that all the fruit particles have settled to the bottom of the container, which is due to the long period of transportation by the vibration of the mechanical displacement. The oscillatory displacements caused by the monomers were able to restore the suspension (true network structure) after re-homogenization.

On the other hand, the oscillatory displacement of xanthan gum – mannose and other composite gums could not restore the suspension (pseudo-network structure) after re-homogenization, mainly due to the destruction of hydrogen bonding between the mating colloids. However, reheating to the gelling temperature above the point, hydrogen bonding reconnection, pseudo-network structure can be re-formed, resumption of levitation.

The manufacturer can change the gel strength of the colloid by adjusting the colloid dosage according to the length of the sales transportation distance in order to reduce or overcome the oscillatory displacement [14]. It is necessary to solve the problems in the production process of suspended fruit drinks thoroughly and efficiently. It is also expected to be highly resistant to acid and thermal degradation, high gel temperature point, does not affect the flavor of the beverage at the same time strong resistance to water precipitation performance of the development of new suspending agent. The development and application of new colloids and the organic compounding of various colloids can help to obtain satisfactory products, which is the future direction of research and development of suspended fruit drinks. The trial production of a dragon fruit suspension drink[56] Add down we use dragon fruit as the main raw material, citric acid, sugar, xanthan gum, sodium carboxymethyl cellulose (CMC-Na), carrageenan and so on as auxiliary materials, to make a dragon fruit suspension drink. I. Materials Dragon fruit (red skin and white flesh varieties), sugar, citric acid, xanthan gum, sodium carboxymethyl cellulose (CMC-Na), carrageenan and so on.

(A) raw material selection Select the fresh dragon fruit with clean surface, no cracks, no frostbite, and check the softness and hardness of the fruit body, gently press the fruit body with a finger to remove the softer texture of the dragon fruit. (ii) cleaning, peeling, cutting the selected fresh dragon fruit in a stainless steel basin, with flowing tap water to rinse its surface, and remove impurities on the surface of the fruit body, etc.. Then, gently peel the pulp and peel separation to avoid damage to the pulp and waste of raw materials. After peeling, check whether the pink skin on the surface of the fruit body is removed or not, if too much pink skin remains, it will affect the sensory quality of the finished product. Finally, part of the peeled dragon fruit cut into pieces, and the other part of the refrigerated standby. (C) the preparation of dragon fruit pulp will be cut into pieces of dragon fruit into the juicer, pulping. Until the pulp is uniform, no fruit particles, and then put into the container refrigerated standby. (D) the preparation of dragon fruit fruit particles after peeling dragon fruit cut into 4 mm3 fruit particles, blanching with boiling water for 10 ~ 15 s. To prevent browning reaction of the fruit particles before use, the cut fruit particles with 0.1% isoascorbic acid solution soak treatment for 30 min. Then, 2% CaCl2 solution at room temperature calcification treatment for 0.5 h. Finally, rinse with purified water for 3-5 times, placed in the refrigerator (about 5 ℃) cold storage. (Finally, rinse with purified water for 3-5 times, put in the refrigerator (about 5 ℃) cold storage standby. (E) the preparation of suspension stabilizer take the appropriate amount of warm water (about 40 ℃) (about 100 mL) add 0.2% xanthan gum and 0.15% CMC-Na composite suspension stabilizer, and keep it in a water bath temperature of 90 ~ 95 ℃ for 2 ~ 3 min, gently stir with a glass rod to make it dissolve. (F) dragon fruit suspension drink mixing take a certain amount of pure water add 15% dragon fruit pulp, 6% sugar, compound suspension stabilizer, heating and make the sugar completely dissolved, then add 0.12% citric acid flavor, and add 6% of the dragon fruit particles. (G) filling filling before the required glass beverage bottles should be selected, cleaning, eliminating sub-bottles, cleaning, pouring in a clean plastic basket, standby. Filling process as quickly as possible, sealing strength should be moderate, sealing tight. (H) Sterilization using pasteurization method, will be filled with suspended drinks placed in 85 ℃ warm water, keep 20 ~ 25 min, after the completion of sterilization, cooling to room temperature.