What is soy plant-based yogurt?

In recent years, with the continuous improvement of people’s living standards the demand for yogurt is also increasing. Combining fermentation agents and plant-based raw materials to make healthy yogurt drinks rich in plant protein and microbial protein is one of the current trends in the development of functional beverages.

Soy Plant Yogurt

Soybean plant yogurt, also known as plant-based yogurt, is a fermented product in the deep-processed soymilk stale products, which possesses a thick organization and viscous taste, and its most important role is to greatly extend the shelf life of soymilk. Compared with animal yogurt, the most prominent advantage of soy yogurt is that it is cholesterol-free and suitable for lactose intolerant patients.

Factors affecting the taste of soy plant yogurt

1. Different ratios of strains used to milk as the main ingredients of yogurt fermentation strains mainly milk lactose as the fermentation substrate, while the instant soy flour as the main ingredients of fermented plant-based yogurt, fermentation strains mainly sucrose as the fermentation substrate. Lactobacillus plays an acidifying role in yogurt fermentation; Streptococcus thermophilus plays a thickening role in yogurt fermentation.

①Classical mixed fermentation This fermentation is the classic strains for processing yogurt: Lactobacillus bulgaricus and Streptococcus thermophilus, which are complementary to each other in their fermentation characteristics, and the yogurt made has the composite health care value of the two strains.

② Lactobacillus plantarum mixed fermentation This kind of fermentation uses Lactobacillus plantarum, Lactobacillus bulgaricus and Streptococcus thermophilus together. Lactobacillus plantarum of plant origin is more suitable for Chinese digestive system and can be used to ferment soy flower or yogurt.

Lactobacillus plantarum is mainly used in conventional food fermentation and is a healthy microbial organic food ingredient. It aids digestion while also relieving intestinal dysfunction and preventing soy allergies.

③ Lactobacillus Acidophilus Mixed Fermentation This type of fermentation uses Lactobacillus Acidophilus, Lactobacillus bulgaricus and Streptococcus thermophilus together. Lactobacillus acidophilus has the function of increasing the vitality of macrophages and lymphocytes, helping digestion, and maintaining the acid-base balance of the intestines.

④ Lactobacillus acidophilus and Streptococcus lactis mixed fermentation of this kind of yogurt is to make use of some kind of symbiotic relationship between the two bacteria to increase the speed of acid production, shorten the fermentation time, and make use of the latter’s property of producing butanedione, so as to improve the flavor of the product, so as to make the yogurt with fine texture, sweetness in sourness, and aroma in sweetness.

⑤ Mixed fermentation of Lactobacillus acidophilus and Bifidobacterium bifidum This kind of fermentation utilizes the mutualistic relationship between Bifidobacterium bifidum and Lactobacillus acidophilus for fermentation. Bifidobacterium bifidum not only produces acetic acid but also synthesizes various vitamins such as vitamin B2 and folic acid, which are supplied to Lactobacillus acidophilus to promote the growth and proliferation of Lactobacillus acidophilus. Lactobacillus acidophilus needs acetate, vitamins and folic acid as nutrients to promote the growth of bifidobacteria. Meanwhile, mixed fermentation can speed up acid production, shorten curdling time and make better flavor.

In short, different enterprises can choose different strains or composite strains according to their own product positioning.

2. Fermentation time and fermentation temperature fermentation temperature: the effect of temperature on fermentation and its regulatory control is one of the most important factors affecting the growth and reproduction of organisms, because any biochemical enzymatic reaction is closely related to temperature changes.

As the temperature rises, cell growth and reproduction accelerate; but as the temperature rises, the rate of enzyme inactivation is also faster and faster, so that the aging advance fermentation cycle is shortened, which has an adverse effect on the fermentation production.

Fermentation time: the time required from the start of inoculation to the termination of fermentation. Fermentation time is too long or too short has an effect on the quality of yogurt; fermentation time is too long, the bacteria breed too much, the taste of yogurt will be too sour; fermentation time is too short, the amount of bacteria breeding is not enough, it will cause the protein coagulation is not good, and the yogurt appeared to be out of the water and thinning phenomenon.

So when the fermentation is over, the yogurt should be put into a low-temperature environment for storage. The most suitable fermentation temperature for yogurt is 42℃-43℃; fermentation time is 7-8 hours.

3. The selection of raw materials and proportion of plant yogurt used in most of the raw materials are derived from plants, auxiliary sugar, stabilizers and modified starch, and sometimes add milk powder to adjust the flavor of the product.

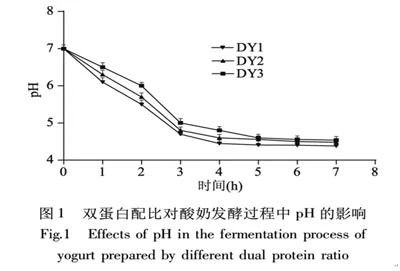

Fermentation slurry can not be less than 11 concentrations, protein content of 3.0 or more. Plant yogurt is conducive to the human digestive function and promotes appetite, lactose fermentation produces a large amount of lactic acid, which can reduce the pH in the intestinal tract, regulate intestinal flora, inhibit the growth and reproduction of harmful microorganisms in the intestinal tract, inhibit the growth and reproduction of pathogens such as pneumonia, mastitis, etc., and also help the body to synthesize B vitamins, and it has a composite aroma of soybeans and yogurt. Figures 1 and 2 indicate the effect of fermentation of milk powder and soybean powder in certain ratios on pH and acidity.

Production process analysis

1, to soybean plant yogurt as an example of the process: process one, soybean screening → peeling (or soaking) → grinding → filtering → enzyme sterilization → standardization → ingredients → filtering → preheating → homogenization → sterilization → cooling → inoculation → packaging → fermentation → refrigeration.

Process II: Soybean milk powder → recovery → dosage → filtration → preheating → homogenization → sterilization → cooling → inoculation → packaging → fermentation → refrigeration.

2, key control points: process one, there is grinding (affecting the protein extraction rate), enzyme (affecting the flavor of soybean taste), standardization (affect product quality and stability), sterilization, inoculation (strain selection affects the flavor), fermentation.

Process II, standardization (affect product quality and stability), sterilization, inoculation, fermentation.

3, process differences: process one, disadvantages: the need for more equipment and energy investment, the need for soymilk making equipment and enzyme processing equipment, key control points more management difficulties. Advantages: strong cost control.

Process 2, disadvantages: relatively small selection of raw materials. Advantages: the required equipment is the same as ordinary yogurt, the key control points are the same, and the process is relatively mature.

If the dairy company as a new product or rich variety is recommended to use the second process. Conclusion

Soybean is the most cost-effective raw material for vegetable yogurt protein base. Instant soybean powder is made by sterilizing, concentrating, spraying and drying soybean milk, which is a kind of plant protein food with high nutritional value.

This food is characterized by easy preservation and convenient consumption. It has the natural color, aroma and taste of soybeans, especially it does not contain cholesterol, which will not cause cholesterol deposition, and contains unsaturated fatty acids, which in turn have the effect of preventing cholesterol deposition from other sources. Therefore it is very popular among the general public.

Soybean plant yogurt made with instant soybean flour, eliminating the tedious process of making soy milk, convenient for consumers to make at home and the environmental pressure of factories, and reduce energy consumption. And instant soybean meal and the use of soy milk to make plant yogurt compared to the uniformity of good, the flavor of the product will not have a greater change.