Properties and product introduction of sodium carboxymethyl cellulose

Sodium carboxymethyl cellulose abbreviated as carboxymethyl cellulose (CMC) is a kind of high polymerization fiber ether produced by chemical modification of natural cellulose, whose structure is mainly composed of D-glucose units connected by β (1→4) glycosidic bonds.

CMC is white or milky white fibrous powder or particle, density 0.5-0.7 g/cm3, almost odorless, tasteless, hygroscopic. Easily dispersed in water into a transparent gelatinous solution, insoluble in organic solvents such as ethanol, 1% aqueous solution pH 6.5-8.5, when pH>10 or <5, the viscosity of the paste is significantly reduced, the best performance in pH=7. Stable to heat, the viscosity rises rapidly below 20℃, the change is slower at 45℃, and the long time heating above 80℃ can make its colloid denaturation and the viscosity and performance drop significantly. Easily soluble in water, transparent solution; stable in alkaline solution, easy to hydrolyze when encountering acid, precipitation occurs when the PH value is 2-3, and precipitation also occurs when encountering multivalent metal salt reaction.

Structural formula: C6H7(OH)2OCH2COONa Molecular Formula: C8H11O5Na

The main reaction is: natural cellulose and NaOH first alkaline reaction, with the addition of chloroacetic acid, the glucose unit on the hydroxyl group on the hydrogen and chloroacetic acid in the carboxymethyl group of the substitution reaction. From the structural formula, it can be seen that there are 3 hydroxyl groups on each glucose unit, i.e., C2, C3 and C6 hydroxyl groups, and the amount of hydrogen on the hydroxyl group of glucose unit replaced by carboxymethyl group is expressed by the degree of substitution, and if the hydrogen on the 3 hydroxyl groups on each unit is replaced by carboxymethyl group, it is defined as the degree of substitution is 3. The size of the degree of substitution of CMC has direct effect on the solubility, emulsification, thickening and stability of CMC, acid resistance and salt resistance and other properties.

It is generally believed that the degree of substitution in the 0.6 ~ 0.7 or so when the emulsification performance is better, and with the degree of substitution, the other properties are improved accordingly, when the degree of substitution is greater than 0.8, its acid resistance, salt resistance performance is significantly enhanced.

In addition, it is also mentioned above that there are three hydroxyl groups on each unit, namely, C2, C3 secondary hydroxyl and C6 primary hydroxyl, theoretically the activity of primary hydroxyl is greater than secondary hydroxyl, but according to the homotopic effect of C, C2 on the -OH group is more acidic, especially in the strong alkali environment its vitality is stronger than that of C3, C6, so it is more likely to occur in the substitution reaction, C6 is second, and C3 is the weakest.

In fact, the performance of CMC is not only related to the size of the degree of substitution, but also related to the uniformity of the distribution of carboxymethyl groups in the whole cellulose molecule and the uniformity of the hydroxymethyl group in each molecule in each unit with C2, C3, C6 substitution. Because CMC is highly polymerized linear compounds, and its carboxymethyl in the molecule there is substitution of non-uniformity, so when the solution is static molecules exist in different orientations, when there is shear in the solution, the linear molecules have a tendency to turn to the direction of the flow of the long axis, and with the increase in the shear rate of the tendency to the stronger, until the final fully oriented arrangement until the final, this characteristic of the CMC is known as the pseudoplasticity of the CMC. The pseudoplasticity of CMC facilitates homogenization and pipelining, so that it does not taste too greasy in liquid milk and facilitates the release of milk aroma.

To use CMC products, mainly we need to have enough understanding of the main index parameters such as stability, viscosity, acid resistance, viscosity and so on. Know how we go to choose the right product.

Low viscosity CMC products, fresh taste, low viscosity, almost no sense of consistency, mainly used in special sauces and beverages, health oral liquid is also a good choice.

Medium viscosity CMC products, mainly used in solid beverages, ordinary protein drinks and fruit juices, the specific choice, according to the engineer’s personal habits. Dairy beverage stabilization, CMC contribution is not small ah.

High viscosity CMC products, application space is relatively large, compared with starch, melon gum, xanthan gum and other products, CMC stability is still relatively obvious, especially in meat products, CMC water retention advantage is more obvious! CMC is also a good choice in stabilizers such as ice cream.

The main indicators of CMC quality are degree of substitution (DS) and purity. Generally DS is different, the nature of CMC is also different; the degree of substitution increases, the solubility will be enhanced, the transparency of the solution and stability is also better. It is reported that the transparency of CMC is better when the degree of substitution is 0.7~1.2, and the viscosity of its aqueous solution is maximum when the pH is 6~9.

In order to ensure its quality, in addition to the selection of etherifying agent, some factors affecting the degree of substitution and purity must be considered, such as the dosage relationship between alkali and etherifying agent, etherification time, water content of the system, temperature, DH value, concentration of solution and salts.

CMC finished product quality is good or bad, mainly depends on the product solution, if the product solution is clear, less gel particles, less free fiber, less impurity black spot, basically determine the quality of CMC is good, if the solution will be placed for a few days, there is no whitening or turbidity solution, or very clear, it is a better product!

Dissolution and dispersion of CMC products

Mix CMC directly with water to form a paste and set aside. In the configuration of CMC paste glue, first in the dosing tank with stirring device to add a certain amount of clean water, in the case of turning on the stirring device, the CMC slowly and evenly spread to the dosing tank, stirring constantly, so that the CMC and the water is completely fused, CMC can be fully dissolved.

The reason for spreading the CMC evenly and stirring constantly when dissolving the CMC is “to prevent the problem of agglomeration, lumping, and reduction of the amount of CMC dissolved when the CMC meets the water” and to increase the speed of dissolution of the CMC. Stirring time and the time of complete dissolution of CMC is not the same, are two concepts, in general, the stirring time is much shorter than the time required for complete dissolution of CMC, the time required for both depends on the specific circumstances.

The basis for determining the stirring time is: when the CMC is evenly dispersed in the water, there is no obvious large lumps of objects, you can stop stirring, so that the CMC and water in the state of mutual penetration and integration. The stirring speed is generally between 600-1300 rpm and the stirring time is generally controlled at about 1 hour.

The basis for determining the time required for complete dissolution of CMC is as follows:

(1) CMC and water completely bonded, there is no solid-liquid separation between the two phenomena;

(2) Mixed paste glue is uniform and consistent state, the surface is flat and smooth;

(3) The color of the mixed paste is close to colorless and transparent, and there are no granular objects in the paste. From the time CMC is put into the dosing tank and mixed with water, to the CMC completely dissolved, the time required is between 10 to 20 hours. In order to produce fast and save time, nowadays, we mostly use homogenizer or colloid mill to disperse the products quickly.

Characteristics and process requirements of CMC use in foodstuffs

The use of CMC has many advantages over other food thickeners:

I. CMC is widely used in food and its characteristics

(A) CMC has good stability

In cold food such as ice lollies, ice cream, the use of CMC, can control the formation of ice crystals, improve the expansion rate to maintain a uniform and consistent organization, can resist melting, delicate lubricating taste, whitening color. In dairy products, whether it is flavored milk, fruit milk or yogurt, it can react with protein within the range of isoelectric point of PH value (PH4.6) to form a complex with compound structure, which is conducive to the stabilization of emulsion and improve the impedance of protein.

(ii) CMC can be compounded with other stabilizers and emulsifiers.

In food and beverage products, general manufacturers use a variety of stabilizers, such as: xanthan gum, guar gum, carrageenan, dextrin, etc., emulsifiers, such as: glycerol monostearate, fatty acid esters of sucrose, etc., for compounding. Can make the advantages complement each other, and play a synergistic effect, reduce production costs.

(C) CMC has pseudoplasticity

CMC viscosity at different temperatures has reversibility, the temperature rises, the solution viscosity decreases, and vice versa; CMC in the presence of shear, the viscosity will decrease, and with the increase of shear, the viscosity becomes smaller. These properties of CMC can reduce the load of equipment and improve the homogenization efficiency in mixing, homogenization and pipeline transportation, which is incomparable with other stabilizers.

Process requirements

As an effective stabilizer, if CMC is not used properly, it will affect its use effect and seriously lead to product scrap. Therefore, for CMC, it is very important to fully and evenly disperse the solution to improve its efficiency, reduce the dosage, improve the product quality and increase the yield. This requires each food manufacturer to fully understand the characteristics of various raw materials, and reasonably adjust their own production process, so that CMC can give full play to its role, especially in the various stages of the process should be noted:

(I) Ingredients

1, with mechanical high-speed shear dispersion method: the use of all equipment with the ability to mix to assist the CMC in the water dispersion, through high-speed shear, so that the CMC uniformly infiltrated in the water, to accelerate the dissolution of CMC. Currently some manufacturers use powder mixer or high-speed mixing cylinder.

2, sugar dry mixing and dispersion method: CMC, sugar according to the ratio of 1:5 mixing, under constant stirring, it will be slowly sprinkled into the CMC fully dissolved.

3, with saturated sugar dissolved in water, such as caramel, etc., can accelerate the dissolution of CMC.

(ii) Add acid

For some acidic beverages, such as yogurt and other acid-resistant products must be used, if the normal operation, can improve product quality, prevent product precipitation, delamination and other phenomena.

1, add acid should be strictly controlled when adding acid temperature, generally should be less than 20 ℃.

2, acid concentration should be controlled at 8-20%, the lower the better.

3, add acid by spraying, along the container than the tangential direction to join, generally 1-3min.

4、Slurry speed n=1400-2400r/m

(C) homogenization

1, emulsification purpose.

Homogenization: the material containing oil and grease, CMC should be compounded with emulsifier, such as monoglyceride, homogenization pressure 18-25mpa, temperature 60-70 ℃.

2、Dispersion purpose.

Homogenization, for a variety of ingredients such as pre-complete homogeneity, there are still some small particles exist, must be homogenized, homogenization pressure 10mpa, temperature 60-70 ℃.

(D) Sterilization

CMC at high temperatures, especially for a long time higher than 50 ℃ temperature, the quality of the CMC viscosity will be irreversible decline, the general manufacturers of CMC at a high temperature of 80 ℃ 30 minutes viscosity decline is quite serious, so you can use the instantaneous sterilization or pasteurization method to shorten the time of CMC at high temperatures.

(E) Other Precautions

1, the selected water quality as clean as possible with well-treated tap water, should not use well water to avoid microbial infection, affecting product quality.

2, dissolving, holding CMC apparatus can not use metal containers, stainless steel containers or wooden pots, ceramic containers. Prevent the infiltration of divalent metal ions.

3、After each use of CMC, the mouth of the bag should be tied tightly to prevent CMC from absorbing moisture and deteriorating.

Answers to questions in the use of CMC

I. Question: How to distinguish low viscosity, medium viscosity and high viscosity from the structure, and will the consistency be different?

Answer:

It is understood that the length of the molecular chain is different, or the molecular weight is different, divided into low, medium and high viscosity, the macro-expression of course corresponds to the viscosity is not the same, the same concentration, the viscosity has a high and low, the stability of the product and the acid ratio and so on has no direct relationship, the main point is to look at the solution of the product.

Second, the question: substitution degree of 1.15 or more of the product specific performance performance, or substitution degree is higher, the product of those specific properties have been strengthened.

Answer:

Product substitution degree is high, the fluidity increases, the pseudoplasticity is obviously reduced, the same viscosity of the product, high substitution degree, the sense of smoothness is more obvious, high substitution degree product solution has a glossy, general substitution degree product, the solution is white.

Third, the question: to do fermented protein drinks is not the choice of medium viscosity on it?

Answer:

Medium and low viscosity products, substitution degree 0.90 or so, acid resistance better products.

Fourth, the question: how can cmc dissolve quickly? I sometimes use it, boiled, still relatively slow to dissolve.

Answer:

Mix and dissolve with other colloid, or use 1000-1200 rpm stirrer to disperse.CMC’s dispersion is not good, hydrophilic, easy to clumping, high substitution degree of the product is more obvious! Warm water dissolution is faster than cold water dissolution, generally do not recommend boiling, CMC products for a long time steaming will destroy the molecular structure, the product will lose viscosity!

Examples of CMC application in acidic milk beverage

I. Theoretical basis

As can be seen from the structural formula, CMC on the hydrogen (Na +) in aqueous solution is very easy to leave (generally in the form of sodium salt), so CMC in aqueous solution in the form of anions, that is, showing a negative charge, and with the amphoteric nature of proteins in the pH is less than the equipotential point, its ability to bind protons -COO- groups Far greater than -NH3 + group gives the ability of proton and show positive charge, 80% of the proteins in cow’s milk for casein, and the isoelectric point of casein in 4.6 or so, the general acidic milk drink pH in 3.8 ~ 4.2, so in the acidic conditions of the CMC and milk proteins can be complexed with the way of charge attraction, the formation of a more stable structure and can be around the proteins. CMC can form a protective film around the protein, and this property of CMC is called microcapsule embedded binding properties.

Suggested formulations for acidic milk beverages

(A) The basic formula of blended acidic milk drink (according to 1000Kg):

Fresh milk (whole milk powder) 350(33)Kg

Sugar 50Kg

Compound sweetener (50 times) 0.9Kg

CMC3.5-6Kg

Monoglyceride 0.35Kg

Sodium citrate 0.8Kg

Citric acid 3Kg

Lactic acid (80%) 1.5Kg

Note:

1) Milk powder can be replaced by partially hydrolyzed protein, control protein ≥1%.

2) The final acidity of the product is controlled at about 50-60°T.

(3) Soluble solids 7.5% to 12%.

(B) lactic acid bacteria drink formula (according to 1000Kg):

Fermented milk 350~600Kg

White sugar 60Kg

Compound sweetener (50 times) 1Kg

CMC3.2~8Kg

Monoglyceride 0.35Kg

Sodium citrate 1Kg

Citric Acid

Note: Use citric acid liquid to adjust the acidity of milk, the final acidity of the product is controlled at about 60 to 70 °T.

Third, the main points of the selection of CMC

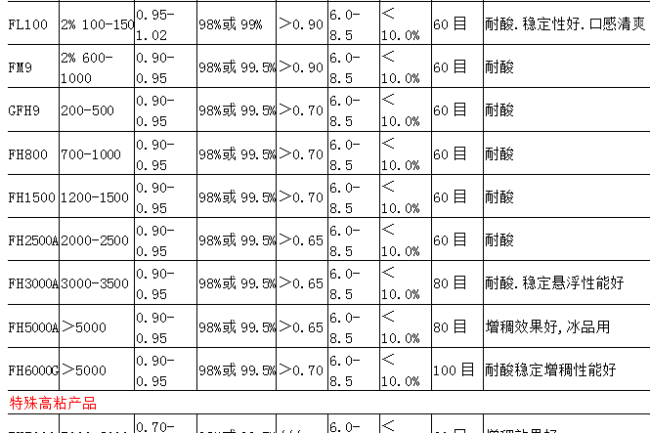

Blended yogurt drinks generally choose FH9 and FH9 extra high (FVH9), FH9 taste thick, add 0.35% to 0.5%, while FH9 extra high is more refreshing, and increase the mixing effect is good, the amount of 0.33% to 0.45%.

Lactobacilli drinks generally choose FL100, FM9 and FH9 extra high (special process production), FL100 generally do taste thick and long shelf life of the product, the amount of 0.6% to 0.8%, FM9 for the use of the most widely used products, its taste thick and product consistency is moderate, the product can achieve a longer shelf life, the amount of 0.45% to 0.6%, FH9 extra high to do! FH9 extra high to do lactobacilli beverage products thick and not greasy, and the amount of addition can be less, the cost is lower, suitable for doing thick lactobacilli beverage, the amount of 0.45% to 0.6%.

Usage of CMC

CMC dissolution: the concentration is generally 0.5% to 2% dissolved in water, before dissolution, it is best to mix well with more than 3 times the sugar dry, and then slowly added to the 65 ~ 85 ℃ stirring hot water, preferably with a high-speed mixer to dissolve, to be dissolved in CMC for about 15 ~ 20 minutes, through the colloid mill again, cooled down to 20 ~ 40 ℃ standby.

V. Acidic milk beverage process points to note

Raw milk (including recovered milk) quality: acidic milk drinks should not be used to make antibiotic milk, mastitis milk, first milk, last milk, the four kinds of milk, the four kinds of milk protein components have changed a lot, and its temperature resistance, acid resistance, salt resistance is also poorer, and affect the taste of the milk.

In addition, these four milk contains a large number of four enzymes (lipase, protease, phosphatase, catalase), these enzymes even at 140 ℃ ultra-high temperature has more than 10% of the residue, in the milk storage period these enzymes will be revived. So that the milk in storage during the odor, bitter, flatulence and other phenomena, directly affecting the shelf life of the product, you can generally use 75% alcohol equivalent experiment, boiling experiment, determination of milk pH and titration of acidity, etc. to choose to test raw milk, normal cow’s milk 75% alcohol experiment, boiling experiment is negative, pH between 6.4 to 6.8, acidity ≤ 18 ° T, when the acidity ≥ 22 ° T when boiling Protein coagulation occurs, pH <6.4 is mostly colostrum or rancid milk, pH>6.8 is mostly mastitis milk or low acidity milk.

(I) Points to note on the process of blended acidic milk beverage

Preparation of yogurt: Preparation of recovered milk: add milk powder slowly into stirred hot water of 50~60℃ (control the amount of water to be more than 10 times of the amount of milk powder) and dissolve it fully for 15~20 minutes (it is better to use colloid mill to go through it again), then cool it down to 40℃ and reserve it.

Prepare CMC solution according to the use of CMC and then add it to the prepared milk solution, mix well, and then use water to roughly quantify (minus the amount of water taken up by the acid solution).

Add the acid solution slowly, continuously and evenly into the milk, pay attention to the control of adding acid time between 1.5 to 2 minutes, adding acid time is too long, the protein stays too long in the isoelectric point, resulting in protein denaturation seriously affecting the stability; too short, resulting in acid dispersion time is too short, the milk local acidity is too large, the protein denaturation is serious, and pay attention to the addition of acid and acid when the milk and the acid temperature should not be too high, it is best to control the milk and the temperature between 20 to 25 degrees Celsius. ~The temperature of milk and acid should not be too high when adding acid, and it is better to control the temperature between 20 and 25℃.

Homogenization is generally used in the natural temperature of milk, control pressure 18 to 25Mpa.

Sterilization temperature: Post-sterilization products are generally used 85 ~ 90 ℃, 25 ~ 30 minutes, other products are generally used 137 ~ 140 ℃, 3 ~ 5 seconds of ultra-high-temperature sterilization.

(B) the process of lactic acid bacteria beverage points to note

Determine the protein content of cow’s milk, add milk powder to make its milk protein between 2.9% to 4.5%, warming to 70 ~ 75 ℃, adjust the homogenizer pressure of 18 ~ 20Mpa homogenization, and then 90 ~ 95 ℃, 15 ~ 30 minutes of pasteurization, cooling to 42 ~ 43 ℃ will be prepared inoculation of bacterial strains according to the amount of 2% to 3%, stirring for 10 ~ 15 minutes to turn off the stirring. Maintain a constant temperature of 41 ~ 43 ℃ fermentation. When the acidity of the milk reaches 85-100 ° T, stop fermentation, quickly through the cold plate cooling to 15-20 ° C to pour tank reserve.

If the protein content of the milk is low, the whey of the fermented milk is too much, easy to appear protein flocculent, using 90 ~ 95 ℃ pasteurization is conducive to the moderate denaturation of proteins, improve the quality of fermented milk, if the fermentation temperature is too low or the amount of inoculum is too small, it will result in too long a fermentation time, excessive growth of stray bacteria, affecting the taste of the product and shelf life. The temperature is too high or the amount of inoculum is too large, resulting in too fast fermentation, more whey precipitation or produce protein hard lumps, affecting the stability of the product. In addition, disposable strains can also be selected when choosing strains, but strains with weak post-acid should be selected as much as possible.

Cool down the CMC liquid to 15~25℃ and mix it with milk liquid and set the volume with water coarsely (minus the amount of water occupied by the acid liquid), and then add the acid liquid slowly, continuously and evenly into the milk liquid (it is better to add acid by spraying method). Stir well and set aside.

Homogenization generally use the natural temperature of milk can be, control pressure 15 ~ 20Mpa.

Sterilization temperature: Post-sterilization products are usually sterilized at 85~90℃ for 25~30 minutes, while other products are usually sterilized at 110~121℃ for 4~5 seconds or 95~105℃ for 30 seconds in ultra-high-temperature sterilization mode.