Sanxan is the first sphingomyelin species independently developed and industrially produced in China, which is produced by fermentation of Sphingomonas sanxanigenens sp.nov. (S.s.sp.nov.), a new species of Sphingomonas.

Sanzanigen is listed as a food additive

1. Approval: On June 2, 2020, the National Health Commission issued the Announcement on Lactobacillus sanxanigenens sp. nov. R0052 and 53 other “Three New Foods” (No. 4 of 2020), approving Sansum as a food additive.

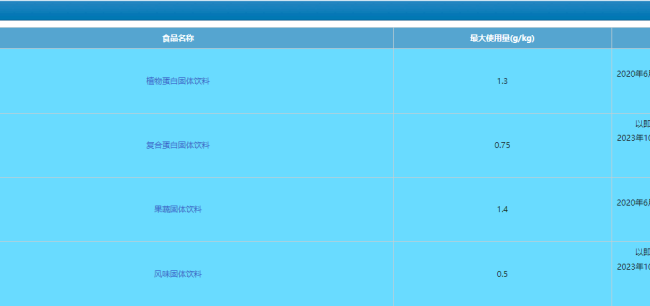

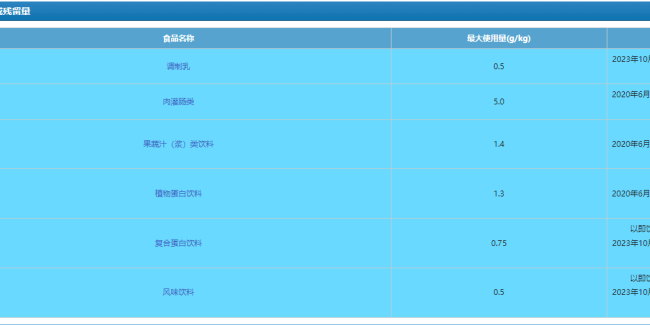

2. Expansion of the scope of use: On October 7, 2023, the National Health Commission issued the Announcement on Peach Gum and 15 other “Three New Foods” (No. 8 of 2023), expanding the trial scope of Trizan gum.

3. Criteria for the use of Sansan gum: (as of February 2024)

Properties of Mizan Gel

1. Gel properties. The solution of trizan gum with mass fraction more than 0.5% is heated to more than 80℃ and then cooled to room temperature to form a thermoreversible gel. In the range of mass fraction of 0.5% to 1%, three characteristic indexes such as gel strength, elasticity and adhesion increase with the increase of gel mass fraction; and after the mass fraction reaches 1.2%, the characteristic value slightly decreases due to the difficulty of uniform dissolution of high mass fraction of trizan gum in water.

In addition, the characteristic indexes are affected by acyl content, pH, metal cation species and mass fraction.

2. Rheological properties. The aqueous solution of Trizan gum is a typical pseudoplastic fluid with shear dilution, no time dependence and no thixotropy.

The viscosity of the aqueous solution increases with the increase of its mass fraction, and the viscosity increases significantly after the mass fraction is higher than 0.4%.

The temperature below 70℃, acid and alkali environment above pH4.0, metal ions, etc. have no significant effect on the viscosity of aqueous solution of Sansan gum, i.e., the aqueous solution of Sansan gum has good temperature resistance, acid and alkali resistance and salt resistance.

3. Emulsification performance and stability performance. 0.2% of Sanzan gum aqueous solution shows good emulsification performance and stability performance, the emulsification index of 0# diesel fuel reaches 100%, which can completely emulsify petroleum alkanes and form stable emulsion.

The effectiveness of polymers in improving the stability of emulsified solutions depends largely on their molecular structure, with the number of acyl substituents having a particularly significant effect, so it is hypothesized that the large number of acetyl and glycerol groups present in Sansan gum may play an important role in its emulsifying properties and stability.

Production and degradation of Sansan gum

1.Production of trizan gum

Compared to other sphingomyelins, trizan gum has a clear advantage – the production

Most of the sphingomyelins require organic solvents to be extracted, which is not only costly but also has a relatively low yield, whereas Sanxan gum is produced by acid precipitation, which requires only controlling the pH of the fermentation broth of the generating strains at about 3.0 to precipitate Sanxan, which is a convenient and cost-saving method, and can lead to large-scale and commercialized production of Sanxan gum.

2.Degradation of Sanxan gum

The release of large amounts of microbial polysaccharides in the environment that are difficult to degrade will have a negative impact on the environment, and the characteristics of the polysaccharide molecules themselves with high molecular weight groups will result in low biological activity, so the study of their degradation is particularly important, not only to solve the environmental problems, but also to improve the antioxidant activity to produce beneficial oligosaccharides products.

Currently, there are two methods for the degradation of trizan gum, the first is oxidation method, by adding hydrogen peroxide and Vc to the purified trizan gum to obtain the degraded product; the second method is the application of degradation bacteria for degradation, a study showed that the viscosity of the trizan gum solution and the molecular weight of the trizan gum polysaccharides were significantly reduced under the synergistic degradation of Aspergillus fumigatus, Pseudomonas fluorescens, and Bacillus megaterium, and the molecular weight of trizan gum polysaccharides was significantly decreased after the degradation. After analyzing the degradation, it was concluded that the rhamnose component of trizan gum was completely degraded. This kind of degrading bacteria can completely degrade trizan gum, which not only solves the environmental hazards of this polysaccharide after its mass application but also improves its antioxidant activity, which provides a strong support for the further application research of trizan gum.

Application of Trizan gum in food

As a self-developed bio-gum in China, Trizan gum has great advantages in nature and cost, but its yield and production rate need to be improved, coupled with the unclear synthesis pathway and narrow application field, which become the limiting factors for the rapid development of Trizan gum industry.

As a food additive approved not long ago, trizan gum is only allowed to be applied in some meat products, dairy products and beverages in limited quantity at present, but the research on the application of trizan gum in other food fields is also being carried out.

1. Application in dairy and beverage foods.

The earliest application of Trizan gum in food production is that of Shandong Jiejing Group Co., Ltd, which used Trizan gum in combination with pectin and sodium alginate as a thickening agent for yogurt.

Hebei Xinhe used Trizan gum in the production of cocoa milk, the addition amount is only 0.04%-0.08%, overcoming the problem of protein precipitation, flocculation, milk fat precipitation; Trizan gum and monostearic acid glycerol ester compounding to get the beverage stabilizers that can be used in the preparation of cereal and protein beverages, under the premise of guaranteeing the nutritional composition of beverages and taste, it can significantly reduce the cost of its production; the combination of Trizan gum and sodium carboxymethylcellulose of acid-resistant type is used to produce a stabilizer. The combination of trizan gum and acid-resistant sodium carboxymethylcellulose has obtained a stabilizer that can be applied to fruit and vegetable juices and their beverages, and it is suitable for a variety of fruit and vegetable juices and their beverages composed of raw materials such as apples, pears, mangoes, etc., and it can make the products have no sedimentation and delamination phenomenon during the shelf-life, and the products have consistent color and lustre and a uniform and stable system.

Chen Yukun et al. three Zan gum and acacia bean gum to 3:7 compound as a yogurt thickener, the yogurt sensory quality and stability of better.

Tianjin Agricultural College of Li Xiaoyan et al. will be three Zhan gum, phosphate, emulsifier compounding to get stabilizer, can be applied to soy, peanuts, almonds, walnuts, coconuts and other plant protein beverage production, the beverage at room temperature after 6 months of storage does not delamination, no precipitation, no flocculation, and compared with the traditional beverage, reduce the amount of stabilizer, both to reduce costs, but also reduce the consumer’s concern about high additives The amount of stabilizers is reduced compared with the traditional ones.

2. Application in meat enema food.

Sansan gum is mainly composed of sugars, lipids and polypeptides, with good rheology and gel thickening, it can effectively control the moisture in meat and sausage food, and improve the appearance, shape, texture, taste and flavor of the product.

Ltd. will be three Zhan gum and konjac gum, carrageenan and other complex preparation of the preparation of compound thickeners, can increase the hardness of minced fish products and the tightness of the organization, so that the appearance of its processing is not concave, processing of good moisture, freezing and thawing under the gel can be kept stable and will not produce aging phenomenon; and three Zhan gum and konjac flour, sodium alginate and other complex preparation of the compound thickening agent for sausage, which can enhance the sausage, and can be used to improve the appearance and shape, texture characteristics, taste and flavor. Thickener can enhance the ability of sausage to retain water and oil and improve the elasticity of sausage body, so that the sausage is more tightly packed inside, in order to increase the preservation time and prevent the sausage from rupture of casings and the quality problem of many air holes on the cut surface.

Beijing Meitian Prospect Technology Co., Ltd. mixes Sanzan gum, sodium hyaluronate, xanthan gum and so on to get compound thickener, which is used in the production process of meat products to make the ingredients fully emulsified, uniformly mixed, to prevent the fat from segregation, to improve water retention and hardness, and to improve the tissue morphology, and it almost does not increase the cost of production.

Henan Tangxi Hydrocolloid Research Institute Co., Ltd. uses Sansan gum as the constituent of hydrocolloid, and prepares a fat substitute, which can be used to prepare low-fat and healthy meat products, which can not only significantly reduce the fat content in meat products, but also improve the taste and nutritional value of meat products.

3.Application in other foods

Sansan gum is hydrophilic and can be formed into gum under cold water, and can be increased under heating conditions. Using this property, it was applied to frozen dough to analyze the freeze-thaw stability of the dough and evaluate the quality of buns produced by it. The results showed that adding 0.5% of Sansan gum in the dough could improve the freeze-thaw stability of frozen dough, and increase the elasticity and chewiness of buns, which improved the quality of the product.

In addition, Sansan gum can be compounded with sodium alginate to prepare edible composite films, which can block oxygen and water vapor from coming into contact with food products, delay food deterioration, and safeguard the quality of food products during storage. The study confirms that trizan gum and sodium alginate have good compatibility and synergism, and the edible membrane formed after compounding has a more regular structure and better performance, which further broadens the application scope of trizan gum in the food field, and is conducive to the diversification of its application and development in the food industry in the future.