The effect of decoction time on the chemical composition and anti fatigue effect of San Guo Tang

Triphala decocyion is a traditional Ayurvedic formula that has been used for a long time, consisting of Terminalia chebula Retz Composed of Phyllanthus emblica L. and Terminalia Billerica (Gaertn.) Roxb. 3 medicinal herbs. In Ayurvedic medicine in India, San Guo Tang is often used as a formula to regulate internal balance, nourish and strengthen the body; In Tibetan medicine, San Guo Tang San is used to treat diseases such as early and late stages of epidemic fever, overwork, etc. In modern times, due to the fast-paced lifestyle, fatigue is becoming increasingly common, and the potential anti fatigue effect of San Guo Tang has also received more and more attention. For example, Triphala oral liquid, developed from San Guo Tang, has always been loved by people for its anti fatigue properties. Research has found that the polyphenols and flavonoids rich in San Guo Tang (accounting for about 39% of its extract) are the material basis for its anti fatigue effect. Polyphenols can effectively alleviate muscle fatigue, mainly due to their ability to resist oxidative stress, maintain mitochondrial function, maintain energy metabolism, regulate bone metabolism, sugar and lipid metabolism, and protein metabolism.

The decoction and extraction of San Guo Tang are important steps in the preparation of related dietary supplements, foods, medicines, etc. Research has found that polyphenolic components, which are the basis of anti fatigue substances in San Guo Tang, are unstable and easily affected by temperature. During the extraction process, they may undergo various reactions such as polymerization, hydrolysis, oxidation, and transformation. According to the Arrhenius equation, temperature is the key factor affecting the reaction, and under heating conditions, this type of reaction will be more intense, directly affecting the efficacy of the drug. However, there is currently no standard for the decoction or extraction time of San Guo Tang. The standards issued by the Ministry of Health require it to be decocted in water, but do not specify the specific decoction time. For example, the “Tibetan Medicine Standards issued by the Ministry of Health” require the usage and dosage of San Guo Tang powder to be “3-4g once, twice a day, decocted in water”, but do not specify its specific decoction time. There are no reports on the transformation of components in the extraction process of San Guo Tang, and the impact of extraction time differences on its anti fatigue efficacy is a research gap. Therefore, this experiment explores the transformation laws of various components during the extraction process of San Guo Tang from the perspective of chemical profile. At the same time, a commonly used physiological fatigue model (weight-bearing swimming fatigue animal model) is selected to investigate the differences in anti fatigue activity of San Guo Tang at different extraction times and its anti fatigue mechanism. By combining chemical component transformation with pharmacological changes, the overall effect of extraction time on San Guo Tang is explored, providing a certain reference for the future production and preparation of San Guo Tang extraction.

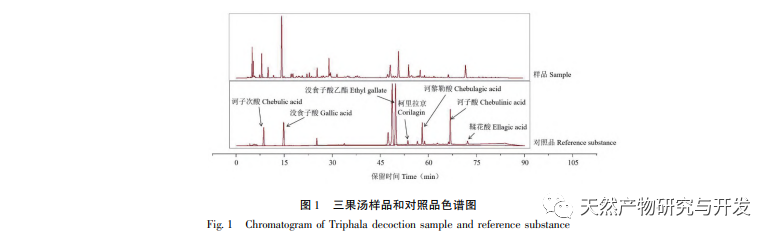

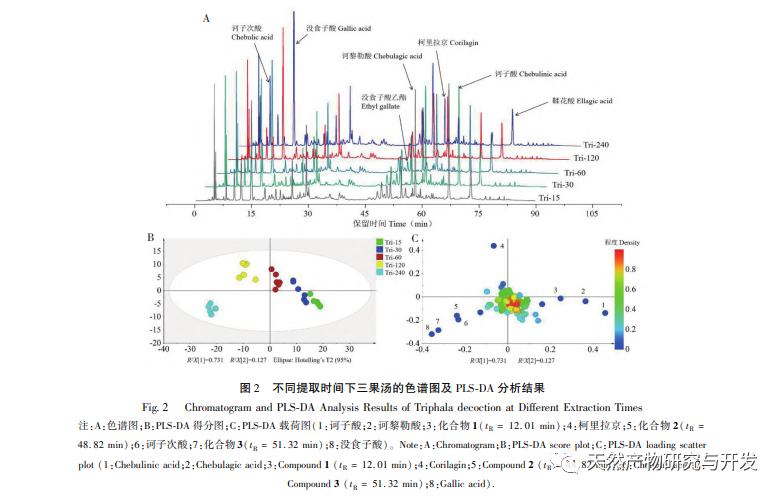

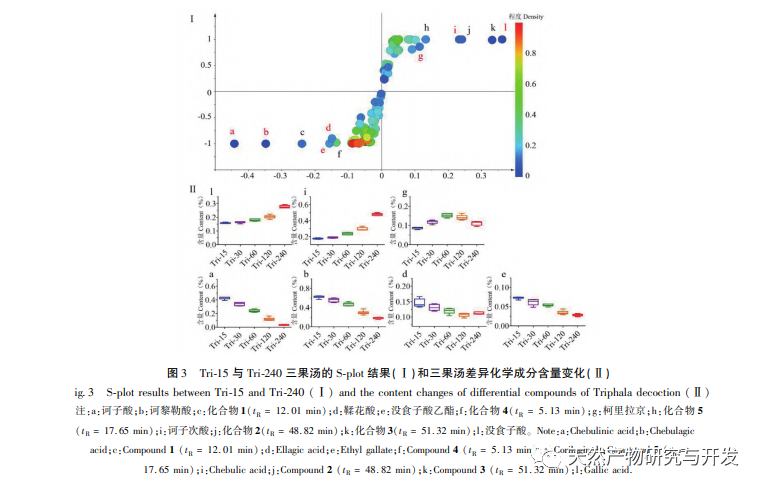

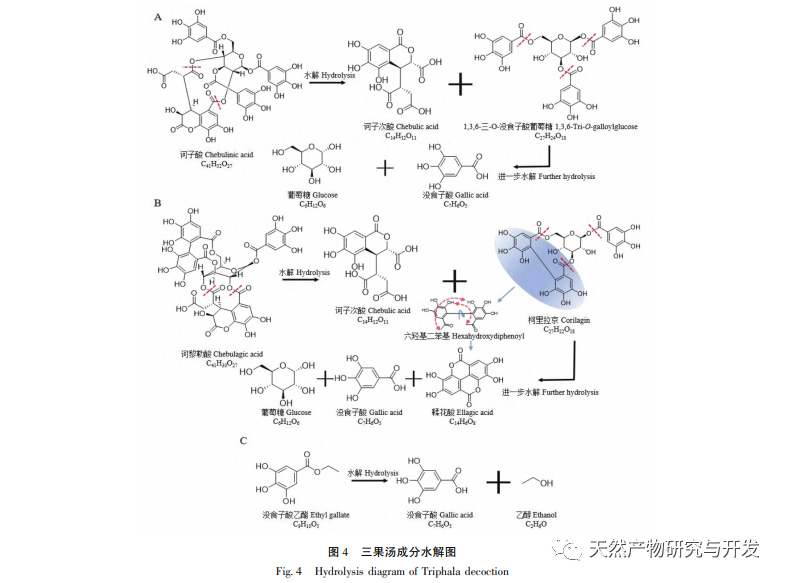

During the processing of traditional Chinese medicine, chemical changes such as oxidation, thermal degradation, and hydrolysis of the main components are often accompanied, which is one of the important reasons for the differences in chemical composition and function of medicinal materials. There were significant differences in the overall quality of San Guo Tang after decoction and extraction at different times. With the increase of decoction time, the content of gallic acid and succinic acid continued to increase, while the content of gallic acid, gallic acid, ethyl gallate, and tannic acid continued to decrease. Corilagin first increased and then decreased. This can be explained by the hydrolysis of tannins. During the extraction process, the large molecule tannin gallic acid undergoes hydrolysis, which produces 1,3,6-triogalloyl glucose and gallic acid. 1,3,6-triogalloyl glucose is further hydrolyzed to produce gallic acid and glucose. Secondly, gallic acid and gallic acid are produced by the hydrolysis of gallic acid. Thirdly, gallic acid and tannic acid are produced by the hydrolysis of gallic acid.

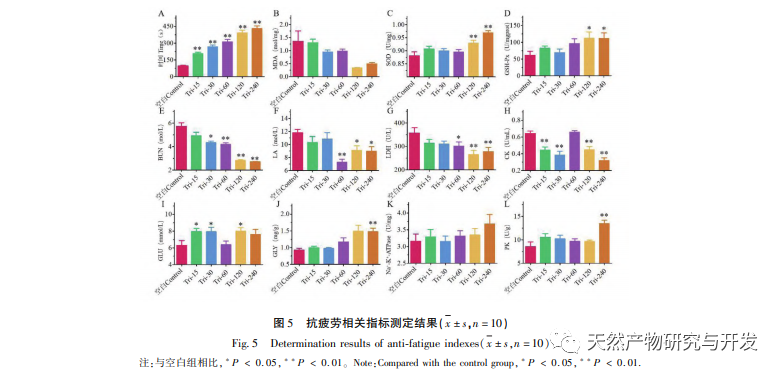

High intensity exercise can cause skeletal muscle redox disorders, hinder ATP production, and lead to fatigue. The production of reactive oxygen species (ROS) during intense exercise can lead to the oxidation of proteins, lipids, or nucleic acids, while also reducing antioxidant capacity. SOD and GSH Px are the main endogenous antioxidant enzymes that alleviate damage caused by excessive oxidative stress by clearing free radicals and their metabolites. MDA is one of the degradation products of membrane lipid peroxidation caused by free radicals and is an important indicator for evaluating cellular oxidative stress. Therefore, the final results showed that San Guo Tang increased SOD and GSH Px activity and reduced MDA levels, proving that it can prevent and reduce oxidative damage caused by fatigue. Excessive fatigue can also lead to metabolic disorders in the body, with elevated levels of lactate, lactate dehydrogenase, urea nitrogen, and creatine kinase. Lactic acid is a metabolic product of glycolysis, while blood urea nitrogen is a metabolic product of proteins and amino acids. During excessive exercise, an increase in lactic acid and blood urea nitrogen can reduce muscle strength, enzyme activity, maximum shortening speed of muscle fibers, and working ability of brain cells, leading to fatigue. Lactate dehydrogenase and creatine kinase are key enzymes involved in anaerobic glycolysis and energy metabolism regulation in muscles, respectively, and are both associated with muscle injury. After administration of San Guo Tang, the levels of these four indicators decreased, indicating that San Guo Tang has the ability to improve the accumulation of harmful metabolites. Energy reserve and ATP production are important links that affect energy metabolism. The consumption of energy reserve and the obstruction of ATP production can lead to exercise fatigue. Energy reserve can be judged by blood glucose levels and liver glycogen content. ATP synthesis ability can be judged by Na+- K+- ATPase and pyruvate kinase (PK) activity. The former can maintain potential balance and protect mitochondria, while the latter is a rate limiting enzyme involved in regulating glycolysis pathways and tricarboxylic acid cycles, catalyzing ATP synthesis. San Guo Tang can increase blood sugar and muscle glycogen content, enhance PK activity, indicating that San Guo Tang can regulate energy metabolism.

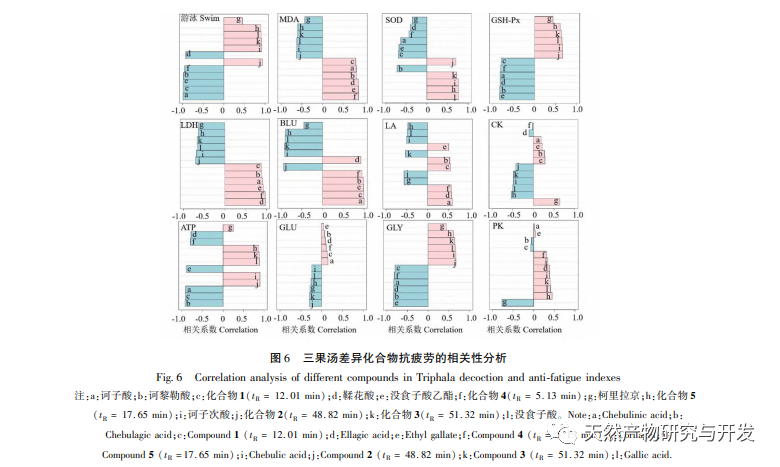

In addition, this study shows that the chemical composition changes that occur during the decoction stage of San Guo Tang will further affect the anti fatigue efficacy of San Guo Tang. Whether it is the improvement of the duration of exercise (weight-bearing swimming) in mice, or the regulation of metabolite accumulation, oxidative stress, and energy balance in the body, San Guo Tang with longer decoction time is significantly better than San Guo Tang with shorter decoction time. This is because the large molecule tannins in San Guo Tang are difficult to be absorbed by the body and need to be hydrolyzed into small molecule tannins such as gallic acid, succinic acid, and tannic acid under the action of the body’s microbiota or enzymes. Then, they are further metabolized into other metabolites such as protocatechuic acid ester derivatives and dibenzopyran-6-one metabolites (mainly urolithin A and urolithin B) under the action of the intestinal microbiota before being absorbed by the body to exert anti fatigue effects. This conversion requires sufficient time, so there are cases where some large molecule tannins are not hydrolyzed and absorbed in time before being excreted from the body, resulting in the loss of a large amount of anti fatigue active ingredients. The heat treatment during the decoction stage promotes the hydrolysis of polyphenols in San Guo Tang, completing the conversion of large molecule tannins to small molecule tannins in San Guo Tang in vitro in advance. This is beneficial for the absorption and efficacy of San Guo Tang in the body, reducing the loss of active ingredients. The correlation analysis of San Guo Tang also proves that the final products of hydrolysis, gallic acid and succinic acid, are the main material basis for San Guo Tang’s anti fatigue effect. This may be related to its ability to prevent lipid peroxidation, protect mitochondrial function, protect biofilm function, improve bone metabolism, glucose and lipid metabolism, and protect nerves. Meanwhile, studies have found that tannic acid can be converted into urolithin by the gut microbiota in the body, and urolithin has been shown to exert anti fatigue effects through the SIRT1-PGC-1 α pathway. This is inconsistent with the results of this correlation analysis, possibly due to the insolubility of tannic acid in water. Most of the tannic acid in Tri-240 decoction is present in the precipitate, which is difficult to detect. However, the drug was administered as a suspension solution, resulting in a mismatch between the content of tannic acid components and the efficacy of the drug in the final results. So, whether tannic acid is the material basis for the anti fatigue effect of San Guo Tang still needs further exploration. At the same time, this also inspires us that San Guo Tang can be considered as a solid formulation in future product development to reduce the loss of efficacy. In summary, this study revealed the changes in the composition of San Guo Tang during the extraction process and its impact on anti fatigue effects, explored the relevant material basis, and provided some reference for the formulation of industry standards and optimization of preparation processes related to San Guo Tang.