Pomegranate for the pomegranate pomegranate plants, native to the Persian Himalayas around Central Asia, that is, now Iran, Afghanistan and other countries, more than 2,000 years ago by the Han Dynasty Zhang Qian (1 ~ 2 centuries BC) by the Silk Road to our country.

At present, all parts of our country have distribution. Pomegranate since ancient times, “Crystal Jade” as the name, listed as a precious fruit, but also because of its sweet and sour taste, cool nature, and rich in nutrients, a wide range of therapeutic effects of the deep for people to love.

Nutritional value of pomegranate

Pomegranate is known as “the world’s strange fruit, the famous fruit of the nine states”, and its fruit is rich in carbohydrates, proteins, a variety of amino acids and essential trace elements and a variety of vitamins.

The edible part of pomegranate accounts for about 15% to 40%, containing about 78.2% water, more sucrose when it is immature, and more converted sugar when it is mature, with the total sugar amount of 11% to 16.8%.

Pomegranate contains malic acid and raffinic acid, acidity varies according to the variety and maturity of the fruit, the general content of 0.4% to 1.0%, the average is 0.77%.

Pomegranate is rich in vitamins and minerals, per 100g of juice containing carotene 0.01mg, VB1, 0.0 4mg, VB2, 0.0 9 rag, V p p, 1.7 rag, VC, 4.6 ~ 11mg, calcium 11 ~ 13 rag, phosphorus 11 ~ 16 rag, iron 0.4 ~ 1.6mg, as well as richer potassium, copper, manganese, zinc and so on.

Also contains protein 0.6% to 1.5% and fat 0.6% to 1.6%, crude fiber 2.7%. Pomegranate whole body is a treasure, containing chemical components in its different parts are different, flavonoids, tannins, alkaloids, organic acids and special structure of polyphenols in the juice, pericarp, leaves, bark in the distribution of each of the weight; pomegranate seeds and other parts of the sterols, phospholipids, triglycerides and other ingredients.

Pomegranate food processing technology

1. Processing of pomegranate juice drink

1.1 Process

Selection of raw materials, a cleaning, a trimming, a crushing, a pulping, a heat treatment, a filtration, a blending, a deoxygenation, a filling, a sealing, a sterilization, a cooling, a labeling, a finished product.

1.2 Operation points

(1) Selection of raw materials: the fruit should be fresh and full, 90% to fully ripe, without rot, pests and diseases and mechanical injury, the diameter should be more than 40mm.

(2) Cleaning and trimming: qualified fruits are rinsed with water, and then the fruit tips and sepals are removed with stainless steel knife.

(3 ) Crushing and pulping: In order to facilitate pulping, the fruits will be crushed first, and then add water at the ratio of 1:1, and pulping will be carried out by colloid mill.

(4) Heat treatment: the above pulp is heated to 80 ℃ and kept for 10min, which can make part of the pectin decomposition protein polythermal denaturation coagulation, but also can passivate the polyphenol oxidase activity. After heat treatment, the nutrients are easy to dissolve, the juice rate is higher.

(5) Filtration: first use 4 layers of gauze for coarse filtration, and then nylon cloth filtration, after several times of filtration, get pomegranate juice.

(6) Blending: according to the requirements of juice drinks on the original juice content and taste needs, the original juice content, sugar, acid blending. The finished product requires a sugar level of 12%, acidity of 0.2%, the original juice content of 20%. At the same time, add 0.1% sodium alginate as stabilizer. Sugar, acid directly added to the mixing tank, heat and dissolve, and then mixed with the original juice, drinking water and so on.

(7) Degassing: Heat the above blended finished product to 60 ~ 70 ℃, degas for 5min, and then homogenize it with colloid mill.

(8) filling and sterilization: first 250m l glass bottles will be washed, sterilized, and then loaded with blended drinks, sealed with the crown capping machine. Put in the high temperature sterilizer sterilizer, sterilization formula for 5-lOmin/110 ℃, with cold water segment cooling to room temperature. The product is milky white, slightly turbid, not layered, no precipitation, with a strong flavor of pomegranate, soluble solids 12%, containing 0.2% acid.

2. Processing of pomegranate ice cream

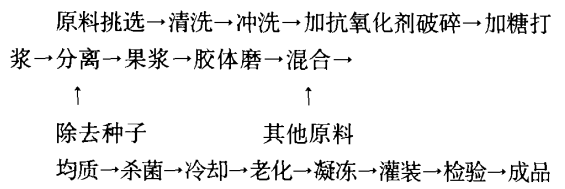

2.1 Process:

2.2 Operation points

(1) Pomegranate pulp preparation: pomegranate fruit picking first, remove corruption, overripe and damaged fruit. Then wash with water, washing water need to add detergent, such as sodium 2 ethylhexanesulfonate or sodium lauryl sulfonate, and then use clean water to thoroughly wash away detergent, cleaning that is roughly crushed fruit, and then pulping machine pulping, separating out the seeds and pulp. Fruit pulp by colloid mill grinding, can crush stone cells, make the fruit particles microfine, improve the organization of the original pulp, the original pulp, can be used in a timely manner or refrigerated standby.

Pomegranate pulp to be stored must be quickly cooled to -18 ℃, cold storage at this temperature. In order to avoid the loss of color, aroma, taste and vitamin C during storage and corruption during freezing, the fruit needs to be added to the antioxidant when crushed, and some sugar, antioxidant (optional SO2) is added during pulping.

SO2 needs to be removed by vacuum short-time evaporation process before use.

(2) raw material mixing and homogenization, aging: the stabilizer and its 10 times the weight of sugar mixed evenly, add water and dissolve and standby.

Skimmed milk powder or whole milk powder, light condensed milk and thin cream with the right amount of water and mix well together to add melted cream and ready stabilizer, the remaining sugar, fruit pulp co-mixed, heated to 65 ℃, put people homogenizer, homogenization process. After microfine particles, 80 ℃, 20min sterilization, put in the aging cylinder, the temperature is reduced to 4 ℃, stirring 4 ~ 6h, so that the hydration of raw materials to enhance; and then from 4 ℃ down to 2 ℃, aging 6 ~ lOh, slow stirring, so that the material combined with the liquid is sufficient to eat without ice crystals.

(3) freezing, filling and storage: freezing at 0 ~ 4 ℃, we must often check the freezing situation, adjust the mixing speed in a timely manner, to maintain the appropriate expansion rate, and coordination with the filling speed.

Filling after freezing, put people -18 ℃ a 20 ℃ freezer or cold storage refrigeration, it will become hard ice cream. Pomegranate fresh fruit ice cream in the cold storage process to maintain a constant temperature, the storage period of not more than 3 months, it is best to sell in a timely manner.

2.3 Technological formula

137g of whole milk powder, 85g of light condensed milk, 85g of cream, 53g of sugar, 18g of egg, 3g of sodium alginate, 2g of monoglyceride, 200g of pomegranate pulp, 417g of water.

3. Processing of pomegranate health fruit vinegar

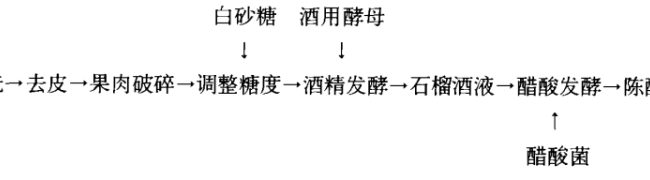

3.1 Process:

3.2 Operation points:

(1)Fruit selection, fruit washing, peeling: the pomegranate fruits used for vinegar making are required to be fully ripe, free of pests and diseases, no mold and deterioration; wash away the impurities and dust on the surface of the fruits to reduce the contamination of the finished products; peel the fruits manually and also mechanically, and crush the pomegranate seeds.

(2) Sugar: Sucrose and pomegranate seeds with broken according to the ratio of 1.2 ~ 1:1, a layer of pomegranate seeds a layer of sugar, placed in porcelain, enameled ware or impregnation pool, sealed to prevent the aroma from escaping, impregnated 6 ~ 10d.

(3) filtering juice: pomegranate seeds and their leachate with gauze filtration separation, that is, to get the pomegranate sugar juice, soluble solids for 65% to 70%. Separation of mountain pomegranate seeds, can be extracted flavonoids and other substances.

(4) Dilution: the original juice according to 1 times the weight of cold water 4 times, with soluble solids of about 16% ~ 18% or so of the dilute pomegranate juice.

(5) alcohol fermentation: dilute pomegranate juice into the fermenter. Raw juice added to the fermenter 4 / 5, leaving empty space 1 / 5, to prevent the fermentation of liquid overflow outside the pool. Access 5% to 7% of the yeast culture stirred well, control the temperature at about 25 ℃ for alcoholic fermentation. The entire alcoholic fermentation process takes about a week to complete, and the alcohol content is about 7%. In order to grasp the changes in the fermentation process, must often check the fermentation of sugar, acid and alcohol content, pay attention to close the mouth of the pool, in order to reduce the volatilization of alcohol.

(6) Acetic acid fermentation: according to the amount of fermented pomegranate juice 1 / 3 add acetic acid bacteria mother liquor for acetic acid. Fermentation temperature control at about 30 ℃, fermentation should be carried out under the conditions of light. It is advisable to stir once a day in the pre-fermentation period to increase the oxygen content in the fermentation liquid. After 10d or so, when the total acidity no longer rises, the alcohol content of trace, that is, pomegranate vinegar.

(7)Aging: move the pomegranate vinegar to the vat for 2~3 months, during the aging process, a series of physical and chemical changes happen in the vinegar liquid, which makes the color of pomegranate vinegar become darker, the aroma is strong, the taste is soft and mellow, and the concentration is increased, and the quality is further improved.

(8)Blending: add 2% salt and 0.08% potassium sorbate into the aged pomegranate vinegar, and adjust the acidity and other indexes according to the standard.

(9)Filtering: filter out the precipitation in pomegranate fruit vinegar to ensure the clarity and transparency of pomegranate fruit vinegar.

(10) Sterilization: adopt instant sterilizer to sterilize, the sterilizing temperature is about 90℃ and the time is 15 s. Or the pomegranate fruit vinegar can be boiled and sterilized, and then bottled while it is hot .

(11) Bottling inspection: bottle and seal the sterilized vinegar, and it will be the finished product after passing the sampling inspection.

3.3 Process parameters

Alcoholic fermentation: initial sugar degree 180B x, initial acidity pH4.2, fermentation temperature 25℃, fermentation time 8d; acetic acid fermentation: fermentation temperature 30℃, fermentation time 10d, initial acidity 1.4%, alcohol 7%.