Microencapsulation Technology

1.1 The concept of microencapsulation technology

Microcapsule is a kind of inclusion or package wrapped with contents by the shell of polymerized material, and the substance loaded inside is called core material, and the substance wrapped outside is called wall material. Microcapsule technology refers to a new type of technology by the polymer of polymer materials as the wall material, so that it is formed on the surface of the core material to form a continuous film, isolation of the contents, so as to form a new type of technology of microcapsules.

Microencapsulation technology can encapsulate solid, liquid or gaseous substances, as far as possible to retain the color, aroma, taste, nutrition and activity of the core material material, and nowadays it has been widely researched and applied in the fields of food, medicine, daily necessities, chemical materials and so on.

1.2 Characteristics of microencapsulation technology

Special core material substances after microencapsulation, its color, morphology, volume, quality, solubility and storability, etc. will be certain changes, under specific conditions, the core material substances will be slowly released so as to play a role.

The particle size of microencapsulated products generally ranges from 1 nm to 1,000 nm. Microcapsules of different shapes, mainly irregular, simple, multi-core type, multi-wall type, filler particles, etc.; according to the functional characteristics of differentiation, including slow-release type, pressure-sensitive, heat-sensitive, light-sensitive, swelling, pH-sensitive type.

1.3 Core material and wall material selection

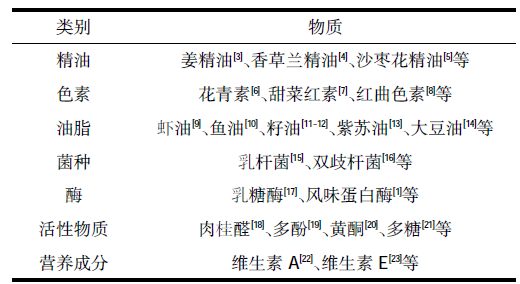

Core material is mostly a single substance, can also be a mixture of several substances, commonly used as a core material can be broadly divided into essential oils, pigments, oils, strains, enzymes, active substances, nutrients, and other categories, the specific core material substances shown in Table 1.

Table 1 Preparation of microcapsules commonly used core material classification

Generally speaking, the core material is only released from the capsule wall of the microcapsule to play its efficacy, the release rate is divided into instantaneous release and slow release of two kinds, the release rate is susceptible to the thickness of the wall material, the size of the hole, the reaction mode and other factors;

The solubility and diffusion coefficient of the core material itself will also have an effect on the release rate, and the general release process of the core material follows the zero-level or one-level release rate equation. In the production and processing of the beverage industry, pigment, active substances and nutrients class of core material selection is more, microencapsulated core material substances added to the beverage, enhance the quality and value of the beverage, enrich the taste and flavor of the beverage.

The selection of wall materials has a great influence on the effect of microencapsulation application, such as permeability, solubility, fluidity and so on. The wall material used should meet the requirements of food additives in national standards, as well as have good film-forming, solubility, emulsification, drying, compatibility, and low viscosity, non-toxic, non-irritant, biodegradable, widely available, low-cost, and do not react chemically with the core material.

In addition, the core and wall materials also have mutual selectivity, usually, oil-soluble wall materials can be used to wrap the water-soluble core materials, water-soluble wall materials wrap the oil-soluble core materials, the surface tension formed between the oil phase and the water phase to make the solution to form a stable water-in-oil or water-in-oil system.

Commonly used wall materials are divided into natural polymer materials and synthetic polymer materials.

Natural polymer materials are less toxic, more viscous and degradable;

Synthetic polymer materials are strong and easy to modify, but less biocompatible.

Plant gums (e.g., gum arabic, pectin) have high viscosity, good film-forming properties and high stability;

Sugars (such as maltose, sucrose, chitosan) have good solubility, but poor film-forming properties;

Starch and its derivatives class (such as carboxymethyl starch, oligosaccharides) from a wide range of sources, no pollution;

Dextrins (e.g. maltodextrin, cyclodextrin) have good heat resistance;

Cellulose classes (e.g. carboxymethyl cellulose, ethyl cellulose) are less toxic and more viscous, but not heat resistant;

Proteins (e.g. gelatin, soybean isolate protein) and lipids (e.g. paraffin, lecithin) have good film-forming and emulsifying properties.PETROVIC et al. prepared microcapsules of sunflower oil by using spray drying with hydroxypropylmethylcellulose as the wall material, and experimentally investigated the effect of anionic surfactants on the process of microcapsule formation.

In practical application, in order to save cost and achieve better embedding effect, two or more wall materials are often chosen to be composite for embedding.CAI Xuran et al. investigated the stability of five proportions of carboxymethyl starch and xanthan gum composite-embedded blueberry anthocyanin microcapsules, and confirmed that the microcapsules were mainly retained in the stomach and released in the intestine by the in vitro release assay.LOLENY TAVARES et al. used whey protein and chitosan complex to microencapsulate garlic extract, which resulted in 50 % to 60 % retention efficiency of phenolic compounds in garlic.

1.4 Preparation methods of microcapsules

There are many methods for the preparation of microcapsules, which can be categorized into physical, chemical and physicochemical methods according to the principle. The specific methods and their advantages are shown in Table 2.

Table 2 Preparation methods of microcapsules

In the beverage industry, spray drying method is often used to produce solid beverages in order to achieve large-scale industrial production. Chai Wisdom et al. used cane juice and cinnamon as raw materials, added maltodextrin and then spray dried to prepare cane juice and cinnamon solid beverage, and the cane juice and cinnamon beverage obtained under the optimal conditions of the process has fast dissolution speed, good quality, sweet and tasty, and has the unique flavor of cane juice and cinnamon.

In the actual production of more core material in the wall material solution mixed homogeneous to form a stable solution, feed to the spray dryer after atomization and high-temperature drying process so that the solvent evaporates quickly, the solute precipitation to get the microcapsules and then added to the juice drinks, solid beverages and so on. The microcapsules prepared by spray drying have good embedding effect, fine and uniform particles, and good solubility.

1.5 Characterization of microcapsules

There are many specific methods for the characterization of microencapsulated products: the use of Fourier transform infrared spectroscopy, X-ray diffraction and other techniques to determine the degree of microcapsule embedding, verification of the embedded structure; the use of scanning electron microscopy to observe the surface structure of microcapsules, the effect of the embedding; the use of particle size analyzer to analyze the particle size distribution of microencapsulated products; the use of thermogravimetric analyzers to detect the thermal stability of microencapsulated products; use of the plotting of the microcapsule’s rate of embedding The microcapsule embedding rate was obtained by mapping; the slow-release property of microcapsules was detected by chromatography, and so on. Storm Sasha et al. established a low-field nuclear magnetic resonance technology combined with partial least squares regression analysis method, rapid, non-destructive and accurate detection of Antarctic krill oil microcapsules embedding rate.

The application of microencapsulation technology in beverage processing

2.1 The role of microencapsulation technology in the application of beverage processing

(1) Liquid beverages can be turned into powder or solid particles after microencapsulation, which is convenient for processing, transportation, storage and consumption.

(2) Protect the volatile, unstable core material from the influence of the external environment (light, temperature, humidity, pH value, etc.), to prevent the core material oxidation and deterioration or slow down the speed of oxidation, and at the same time to avoid interacting with other components in the beverage adverse reactions, resulting in harm to human health.

3)Improve the chemical stability of the product and prolong the storage period.

4)Control the release location, release time and release rate of the core material in the human body, so that the active ingredients with therapeutic functions and so on can be effectively and accurately released, and promote the absorption and utilization of the human intestinal tract.

(5) Mask the bad smell of the core material itself, such as fishy, spicy, bitter, etc., to improve the taste and flavor of the beverage.

6)Maximize the original color, aroma, taste as well as biological activity of the beverage, preserve the nutritional value or even improve the nutritional value.

(7) Reduce the amount of food additives added to reduce the damage to human health.

2.2 Application of microencapsulation technology in tea beverages

Tea because it contains tea polyphenols and other substances beneficial to human health and loved by consumers, but tea polyphenols are easy to oxidize under alkaline conditions, easy to react with caffeine, proteins and other substances to generate tea cheese; vitamins in tea are easily damaged by heat; aromatic substances are easy to volatilize or release undesirable flavor; pigments are easy to decompose in the light conditions, and some of them will also appear cloudy and precipitated, browning soup color, aroma deterioration Some of them will also have turbidity and precipitation, browning of soup color and deterioration of aroma.

The application of microencapsulation technology in the production and processing of tea beverages can effectively solve the above problems. The application of microencapsulation technology can protect the tea polyphenols, vitamins, aromatic substances and pigments in tea beverages, prevent the volatilization of the ingredients, maintain the color and flavor of tea, improve the stability and resistance to light, heat, acid and alkali, and extend the shelf life. Ning Enchuang et al. prepared microcapsules from spray drying of the original liquid of Camellia sinensis polyphenols, and the tea polyphenols were able to retain 81.23 %. Chen Xin pointed out that adding a kind of milk fat microcapsule to tea beverage can enhance the taste and increase the nutritional value.

In the production of instant tea, to maintain the original flavor, color and aroma of tea is the key, adding thrive-cyclodextrin can not only be embedded in the flavor components to avoid its loss, but also prevent the production of tea cheese, the production of tea beverages with strong aroma and good color.

2.3 Application of microencapsulation technology in dairy beverages

In order to ensure that the nutrients in dairy products are not decomposed, microencapsulation technology is used to process the nutrients, so that the milk powder produced has a uniform texture, good flavor and delicate taste. Dai Yi et al. pointed out that microencapsulation of fatty acids added to infant milk powder can ensure the nutritional quality and safety of the formula, improve the stability of fatty acids and slow down oxidation. Docosahexaenoic acid (DHA) is an unsaturated fatty acid, which is essential for the growth and development of infants and young children, but is prone to oxidation and discoloration, resulting in off-flavors.

Microencapsulated DHA added to milk powder can avoid the fishy odor and also improve the solubility of milk powder. The use of microencapsulation can also produce many different flavors of dairy products, such as flavored milk powder, beer milk powder, foaming milk powder, ginger milk powder and so on. Microencapsulation of Lactobacillus acidophilus into yogurt can enhance the water holding capacity of yogurt and increase the protein content, and it has been experimentally confirmed that the properties of this microencapsulated Lactobacillus acidophilus can remain stable for 10 weeks.

Sung Ahn et al. studied the process of enteric lactase microcapsules, and verified that the in vitro release rate of hydroxypropylmethylcellulose phthalate microcapsules is better than that of microcapsules embedded in zeinolysin, and that this kind of microencapsulated lactase can be applied to milk and yogurt to solve the problem of insufficient secretion of lactase in the human body and alleviate the symptoms due to lactose intolerance, so as to ensure the health of human beings.

2.4 Application of microencapsulation technology in functional drinks

Microencapsulation technology has many applications in the production of functional beverages, the most promising applications, probiotics to maintain the balance of the human intestinal flora, the survival of the conditions require high, made of probiotic microcapsules, can improve the activity and stability of probiotics in the intestinal tract, add probiotic microencapsulation production of juice beverages, milk beverages have a broad market.

MAS Hara SOUNGA B A F et al. used whey isolate protein-oligofructose complex as wall material, Lactobacillus acidophilus and Lactobacillus casei as core material to prepare probiotic microcapsules, which were added to mashed bananas to lyophilized into powder and simulated the treatment of human gastric and intestinal fluids, and the test showed that the banana powder with the addition of the embedded probiotic microcapsule maintained high bacterial viability and good storage stability.

Ding Ke et al. microencapsulated Ganoderma lucidum strains, the filtrate of fermentation and citric acid, sucrose, honey in accordance with a certain proportion of the blend, after homogenization, filling, sterilization made of fermented beverages, nutrient-rich, better taste.

Cai Xiangyang and other microcapsules prepared with safflower seed oil to develop a functional composite beverage, through human experimental research shows that this drink on the athlete’s body metabolic ability to promote, long-term drinking can also improve sports performance.

2.5 The application of microencapsulation technology in fruit juice drinks

The use of microencapsulation technology to produce fruit juice drinks, usually with sodium alginate, natural fruit juice or composite juice as raw materials, different flavors of microencapsulated juice drinks with a wide range of raw material sources, simple process, in the production process is not easy to make too much loss of nutrients, consumers can experience a rich taste when drinking.

Liu Chunju et al. applied citron essential oil microcapsules to fruit juice, which retained a variety of beneficial aroma components in the essential oil, with characteristic flavor and high acceptance, and the application of this essential oil in fruit juice has a great value for development and utilization.

Chen Jianbing et al. used the microencapsulation technology of hesperidin embedded, added to the orange juice drink, through the study of the impact on the quality of juice, to determine the optimal formula for: the original juice concentration of 30 %, hesperidin microencapsulation 0.8 %, stabilizers 0.2%, the orange juice drink produced under these process conditions has a good flavor, hesperidin content of up to 0.82 g/L, and at the same time to improve the juice drink Nutritional value.

There are also studies of apple juice with lipids embedded into microcapsules, and then added to water to make microencapsulated apple juice, which is beneficial to human absorption, longer retention time than ordinary apple juice in the body, and high bioavailability.

NAMBIAR et al. obtained microencapsulated coconut juice using spray drying and experimentally demonstrated that microencapsulation protects phenolic compounds from effective controlled release under specific conditions. In addition, the effect of gelatin on clarification of fruit and vegetable juices is also related to the application of microencapsulation technology.

2.6 Application of microencapsulation technology in solid beverages

In the United States, microencapsulation technology is used in more than half of the solid beverage production processes. Wang Yutong et al. mixed grain puffed powder as the wall material embedded thrive – carotene, spray drying prepared a microencapsulated solid beverage, so that the solid beverage has a better solubility and fluidity, and the nutritional value has been improved.

In the production and processing of instant coffee, microencapsulation can protect unstable alcohols, aldehydes, and ketones from decomposition, which is essential for providing the unique flavor characteristics of coffee.

Aerated foaming powder obtained by microencapsulation can make the beverage produce rich foam. Phytomass produced through microencapsulation technology can be used in the ingredients of coffee and milk tea to increase the milky and smooth texture and improve quick solubility. Microencapsulated particles encapsulating natural fruit juices were added to solid beverages, which are natural and nutritious with a fruity odor. Wu Shudong et al. extracted flavonoids from citrus peel residue and added them into solid beverages after embedding them with thrive-cyclodextrin, which resulted in a delicate brewing flavor and moderate sweet and sour taste.

Prospect and Outlook

The application of microencapsulation technology simplifies the traditional beverage production process, promotes the development of beverage industry from low level to high depth direction, and creates many valuable products. With the maturity of the technology, microencapsulation technology is also gradually applied to the use of acidulants, preservatives and other beverage additives, microencapsulation technology has become an important means to promote the continuous progress of the beverage industry.

Currently China’s microencapsulation technology is in a rapid development stage, according to the market demand and the current situation, further theoretical research and wide application, for the development of new environmentally friendly and non-toxic wall materials and core material excavation, as well as to broaden the means of functional evaluation and so on are of great significance. Nowadays, microencapsulation technology is developing in the direction of micronization, high quality and environmental protection, and in the future, microencapsulation technology will play a greater role in the beverage industry, and continuously develop new products that are beneficial to human health, make greater breakthroughs, and bring more benefits to human beings and society.