Optimization of licorice polysaccharide alcohol precipitation process based on improved entropy weight method combined with TOPSIS model and BPNN modeling

According to literature reports, licorice polysaccharides are one of the main active ingredients of licorice, with physiological activities such as anti-tumor, anti-inflammatory, antiviral, and immune regulation. They have become a research hotspot for exploring the pharmacological active ingredients of licorice. Currently, research on licorice polysaccharides mainly focuses on extraction processes, purification techniques, and pharmacological activity studies. Research has shown that water-soluble licorice polysaccharides are a multi-component, highly branched, and protein linked heteropolysaccharide. Pharmacological research has found that purified polysaccharides have lower pharmacological activity than crude polysaccharides. It is speculated that the addition of chemical reagents, complex purification steps, and protein loss are the main reasons. This article will focus on optimizing the alcohol precipitation process of water-soluble components in licorice, licorice polysaccharides.

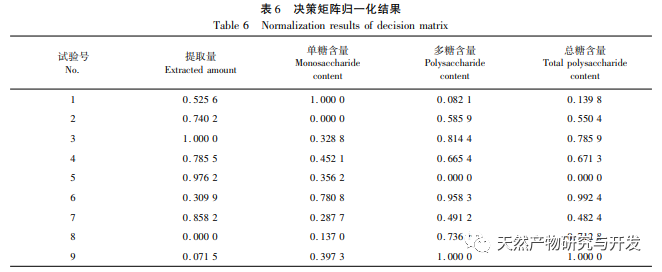

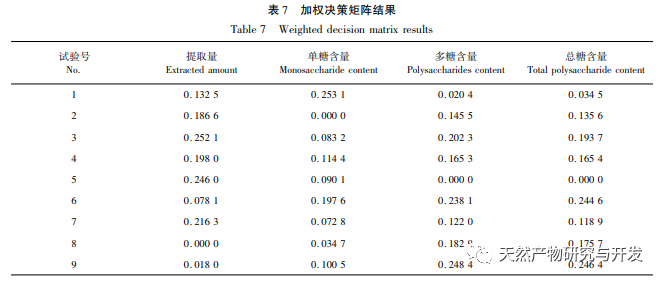

The information entropy theory, as an objective weighting method, is widely used in the optimization research of multiple indicators involved in the extraction process of traditional Chinese medicine and compound formulas. However, when the entropy weight of the traditional entropy weight method is greater than 0.5, changes in individual data will cause a doubling of the weight, thereby affecting the determination of process parameters. Therefore, this article adopts an improved entropy weight method to effectively overcome its shortcomings, improve decision-making accuracy, obtain more reliable data, and make the results more scientific and reasonable. TOPSIS method ranks experimental plans based on the proximity between the evaluation object and the idealized target, and converts multiple indicators into comprehensive indicators. It is a multi indicator decision analysis method that can reflect the overall situation of the sample. In recent years, scholars have combined TOPSIS method with entropy weight method to assign weights to evaluation indicators, thereby comprehensively evaluating experimental schemes. This method can effectively avoid subjective interference of human factors in the experimental results, making the evaluation results more objective and comprehensive. This method has been widely used in the comprehensive evaluation of traditional Chinese medicine quality and is suitable for the process optimization problem in this study. BP neural network (BPNN) can break the limitations of conventional experimental designs such as orthogonal design and star point design in optimizing optimal parameters at a predetermined level. By simulating the processing of complex information by the human brain nervous system, a mathematical model can be established to study complex nonlinear relationships.

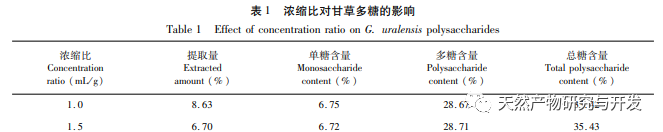

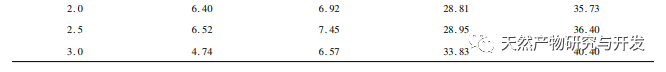

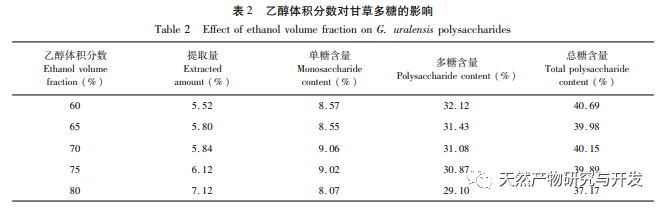

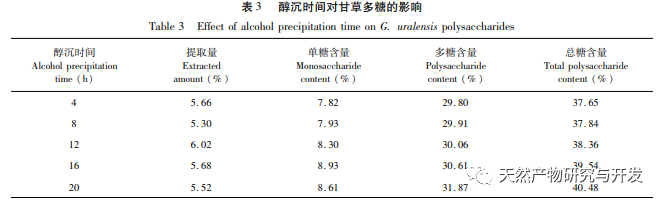

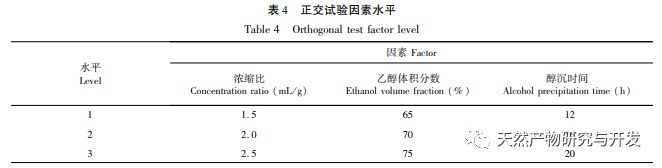

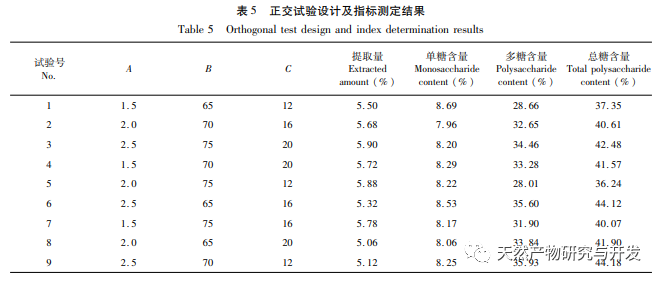

Through literature review, it was found that alcohol precipitation time, ethanol volume fraction, and relative density of concentrated solution have a significant impact on the alcohol precipitation effect of polysaccharides. Therefore, our research group used licorice polysaccharides, monosaccharides, total sugar content, and extraction amount as evaluation indicators, processed experimental data using improved entropy weight method and entropy weight TOPSIS method, studied the main factors of licorice polysaccharide alcohol precipitation, compared the applicability of the two analysis methods in orthogonal design, determined the optimal alcohol precipitation process, and then used BP neural network modeling for simulation optimization to seek the optimal alcohol precipitation process parameters for licorice polysaccharides, in order to select a stable and feasible alcohol precipitation process for licorice polysaccharide preparation, and provide scientific basis for its further development, utilization, and comprehensive quality control.

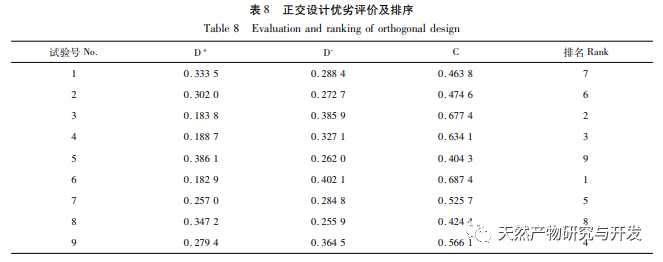

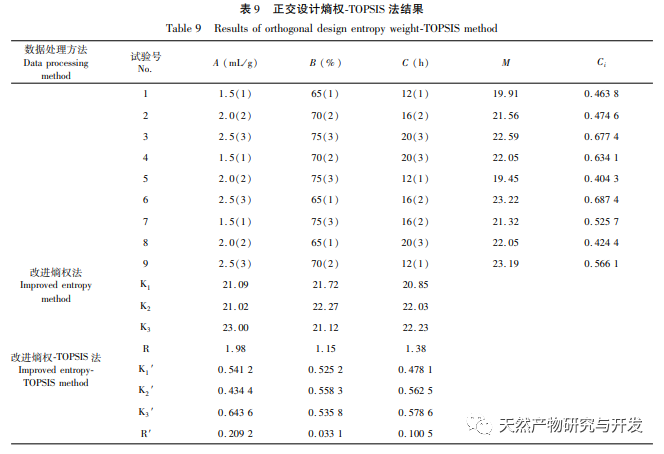

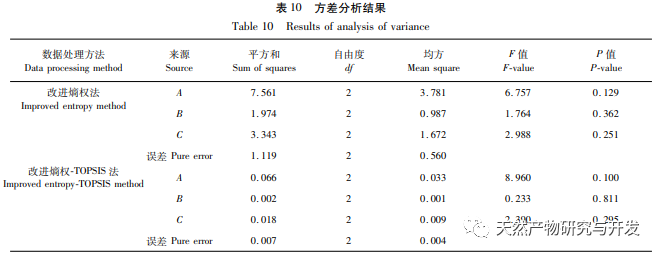

The pharmacological effects of traditional Chinese medicine are the result of the coordinated action of multiple components, and the mixed total sugars contained in traditional Chinese medicine extracts work together to make polysaccharides better exert their pharmacological effects. There is a view in the industry that “the purer the polysaccharides, the lower the activity”. Previous literature on the extraction and alcohol precipitation process of polysaccharides in licorice has mainly evaluated the extraction amount and polysaccharide content (or yield) as indicators, and the optimization results are difficult to reflect the complex inherent nature of polysaccharides. Existing research mostly uses licorice powder as the extraction raw material, and the crude polysaccharides obtained in the later stage need to be purified by Savage method, ether, acetone, methanol and other chemical reagent methods. The reagents used in the purification process are relatively harmful to the human body. The early crushing treatment, ethanol or ether degreasing processes not only increase production costs and time, but also seriously endanger the physical and mental health of operators. Moreover, the chemical reagents used for impurity removal and degreasing are mostly prohibited in the production of traditional Chinese medicine preparations. Therefore, in order to optimize the alcohol precipitation process of licorice polysaccharides, this study takes licorice decoction pieces as the research object. Based on single factor experiments, the main factors such as concentration ratio, alcohol precipitation time, and ethanol volume fraction are selected, and licorice polysaccharides, total sugars, monosaccharide content, and extraction amount are used as evaluation indicators. The improved entropy weight method combined with TOPSIS model method is used to process the orthogonal experimental data, and BPNN modeling simulation is used for process optimization. Comparing the results of using the improved entropy weight method alone and the improved entropy weight combined TOPSIS method, it was found that the improved entropy weight TOPSIS method can fully utilize the original data information, comprehensively evaluate the orthogonal experimental results to obtain the optimal parameter combination, effectively avoid subjective factors in the optimization process, improve decision-making accuracy and scientificity, and make the results more reliable. Finally, the optimal alcohol precipitation process for licorice polysaccharides was determined to concentrate the extraction solution to 2.5mL/g, adjust the ethanol volume fraction to 70%, and precipitate for 20 hours.

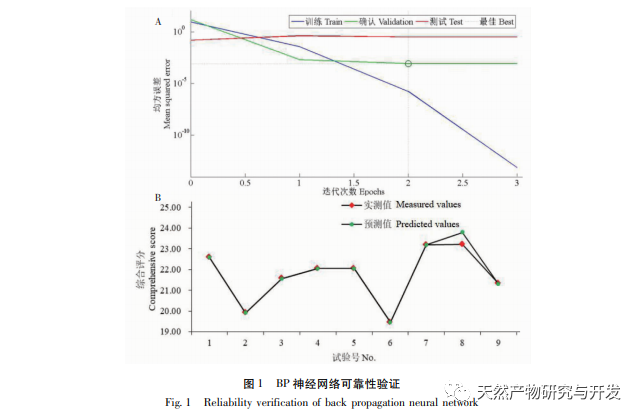

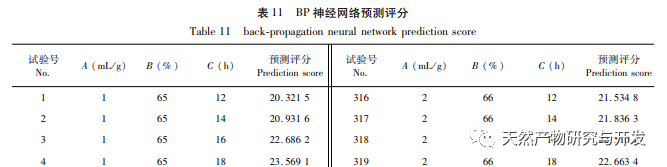

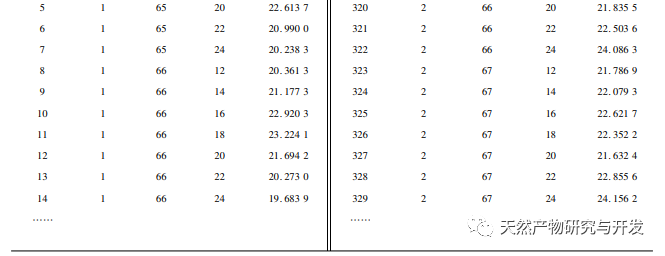

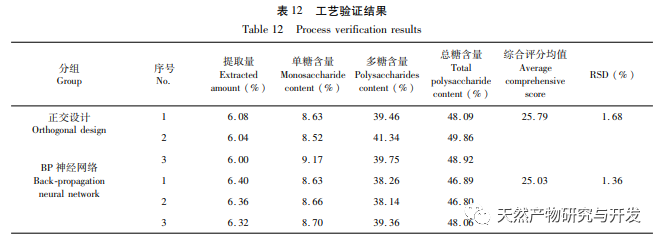

On the basis of orthogonal experiments, a BP neural network model was constructed using Matlab 12.0 software. By learning and training the orthogonal experiment data, a network model with good accuracy, stability, and reliability was obtained. Using the sim function simulation optimization, the optimal process was obtained as follows: concentrate the extraction solution to 2.0 mL/g, adjust the ethanol volume fraction to 67%, and precipitate with alcohol for 24 hours. After process validation, it was found that the comprehensive score of the BPNN modeling optimization result was slightly lower than that of the comprehensive scoring method and the improved entropy weight TOPSIS method, but its RSD value was small. The BP neural network has strong self-learning ability and the resulting process is more stable. Therefore, the BPNN modeling optimization result was determined to be the optimal process for licorice polysaccharide alcohol precipitation.

This experiment determined the level of factors affecting the alcohol precipitation of licorice polysaccharides through a single factor study, arranged the experiment using orthogonal design, and processed the experimental data using an improved entropy weight method to overcome the shortcomings of traditional entropy weight methods, where slight changes in the entropy weight of a certain indicator cause corresponding weight doubling changes. Multiple indicators were selected for comprehensive evaluation to optimize the alcohol precipitation process of licorice polysaccharides. By comparing the results of the comprehensive scoring method and the improved entropy weight TOPSIS method, the importance of factors affecting licorice polysaccharide alcohol precipitation was determined. The orthogonal parameter learning was trained using a B neural network for simulation optimization. Nonlinear problems were modeled and optimized without increasing the number of experiments, making up for the shortcomings of previous optimization experiments. The obtained process parameters were more scientific and reliable, providing objective basis for further development, research, and large-scale production of licorice polysaccharides, and providing new ideas for related process optimization issues.