Gluten Application Overview

Gluten (wheat gluten protein) is wheat, corn and other grains as raw materials, through scientific processing and a natural plant protein, crude protein content of more than 75%, composed of wheat alcohol soluble proteins and wheat gluten at a ratio of about 1:1.

Gluten has strong water absorption, viscoelasticity, film molding, adhesion thermo-coagulation, fat-absorbing emulsification and other physical properties, while rich in glutamine and other functional amino acids. At present, glutamine is widely used in food processing industry and animal nutrition and feed industry, used to improve the taste and nutritional properties of food, improve the nutritional value of feed, has a good application prospect.

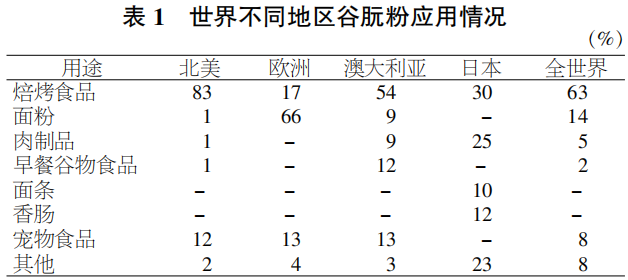

China’s total annual output of wheat in more than 100 million tons, gluten processing raw materials are sufficient, with obvious processing and application advantages. According to statistics, the global annual output of gluten is about 600,000, China is about 100,000 t. Gluten in North America, Europe, Australia, Japan and other countries have a wide range of applications in different industries (Table 1). With the increasing production of gluten and the changing trend of market demand diversification, the deep development and utilization of gluten is particularly important.

Research on the application of gluten in the food field

2.1 Bread, cakes and other new types of noodle foods

In recent years, as people’s health consciousness increases, consumer demand for coarse grains, caused by the pastry industry formula and processing technology innovation, pastry products are also increasingly rich in variety.

Usually the wheat protein content in bread flour is small, weak gluten, bread flour added coarse grains will reduce the dough formation, which in turn reduces the pliability, elasticity and color of pasta products, can not meet the needs of food baking and processing.

Gluten has good water retention and viscoelasticity, can maintain the internal moisture of the bread, delay the aging of bread flavor, so that the bread texture is uniform, moderate elasticity, better taste, and at the same time to enhance the nutritional balance of pastry products, enhance the degree of consumer choice.

Li Yongjun added 65% wet gluten to buckwheat bread, which enhanced the smoothness and elasticity of the dough and improved the sensory quality of the bread products.

Yu Shuxi et al. added 12% gluten and 0.15% transglutaminase to flour to make sprouted brown rice bread, which increased the protein content and improved the color of the bread.

Dang Bin et al. added 6% gluten to barley nutritious bread, which increased the specific volume of the bread and improved the taste and sensory score of the bread.

In addition, Lu Fei et al. improved the rheological properties of bread by adding gluten to soybean dregs bread, thus improving the quality of bread. The amount of gluten added depends on the gluten strength of the flour.

Qi Linjuan et al. compared the sensory qualities of two types of breads with the addition of gluten as a variable, and the results showed that the bread with gluten added was large and had a high sensory score, but too much gluten would make the bread core pores too large, which resulted in a poor textural structure and reduced the satisfaction score of the bread.

Gluten can also be applied to the production of cake-like products, Zhang Hongyin et al. used acylation to modify gluten added to bread, compared the functional properties of gluten and succinylated wheat gluten protein, the results show that acylated wheat gluten protein introduces hydrophilic groups, which can significantly improve the solubility, emulsification, foaming, and bubble stability, and its substitution for cake oil is applied to the production of cakes that It can achieve the effect of uniform porosity, delicate, flavorful and soft.

2.2 Dumplings, noodles and other traditional noodle foods

In the northern region of China, noodles and dumplings occupy a large proportion in the structure of staple food. Adding gluten to noodle food can improve the palatability, viscosity, smoothness and other indicators of noodle products.

Many studies have shown that the addition of gluten can increase the protein content of noodles, increase the hardness, viscoelasticity, resilience, maximum shear force, and promote the formation of gluten network structure. In addition, the addition of gluten in the dough can also change the rheological properties of the powder to achieve the effect of reducing the dough stabilization time, reducing the degree of weakness, and improving the comprehensive index.

The addition of gluten to barley flour by Wen Jiping et al. enhanced the water absorption of the flour and increased the output rate of the product.

Fan Suqin et al. added gluten to oatmeal noodle production, which reduced the starch dissolution rate and improved the quality of oatmeal noodles.

Su Liping et al. added gluten in the production of buckwheat noodles to make up for the alcohol soluble proteins in buckwheat flour, giving it better elongation and viscoelasticity.

Sun Jiaojiao et al. added gluten improver in corn noodles to overcome the difficulty of forming dough mesh structure and rough taste during corn flour processing.

Xu Mengmeng et al. showed that gluten can improve the quality of sweet potato noodles. When sweet potato starch and gluten are used as raw materials to make noodles, excessive sweet potato starch will have a negative effect on the noodles, and when sweet potato starch is added at 20% and gluten is added at 2.7%-3.7%, the quality of noodles is similar to that of noodles made from wheat flour.

Wang Lei et al. studied the effect of gluten addition on the rheological properties of braised noodles, and the results showed that the moderate addition of gluten can significantly improve the sensory score, hardness, adhesion and other indicators, and reduce the rate of cooking loss, and the optimal additive amount is 2%~3%.

Ban Jinfu et al. added 9.0% gluten to flour to optimize the quality of dumpling skin. Zhai Aihua et al. added gluten to modified corn and wheat flour mixture to improve the quality of dumpling flour.

Li Changwen et al. applied gluten to the production of frozen steamed buns, when the amount of gluten added to 2%, frozen steamed buns sensory quality, specific volume, softness is better, excessive addition of gluten will make frozen steamed buns lower quality.

Shi Xueshen et al. added 1% of gluten in the flour and 1% of the yeast production of steamed bread, steamed bread scores and specific volume and other aspects of the indicators have been improved.

2.3 Meat

Gluten applied to animal meat products can improve the viscoelasticity and thermosetting properties of meat products and play the role of adhesive.

Ma Ge Li et al. added gluten in fish cake and fish sausage, enhanced the elasticity of the fish cake, and solved the contradiction of fish sausage quality degradation due to heat sterilization.

Peng Haiping and other gluten as a binder for steak bonded meat, poultry rolls, canned hamburgers and bread slices and other processing and production.

Gluten can be used as a high-quality vegetarian ingredient to replace meat products. Kong Xiangzhen et al. showed that gluten can be processed into granules to replace frozen minced meat Yuan or processed into a paste or fibrous protein products as a substitute for minced meat fillings. However, in the processing of livestock and poultry meat products should pay special attention to the sterilization temperature of livestock and poultry meat 70 ~ 75 ℃, which has a certain gap with the thermal solidification temperature of 80 ℃ gluten, and therefore used as a binder gluten should be modified.

2.4 Food film production

Early food packaging commonly used plastic products, but plastic products are difficult to degrade, affecting the inherent flavor of packaged food shortcomings. Gluten has a uniform texture, strong mechanical properties, relatively insoluble in water, degradable, biocompatible and other advantages, can be widely used in the production of edible film.

Peng Haiping et al. used wheat gluten protein as raw material to make simple gluten film, and determined the ratio of wheat gluten and glycerol 3.5:1.0 film-forming process.

Gluten membrane can be divided into simple membrane and composite membrane 2 categories. Composite membrane can be divided into 3 types of composite membrane with protein, composite membrane with lipids, composite membrane with polysaccharides.