Due to the presence of natural coloring and impurities generated during processing and storage, edible fats and oils can have some adverse effects on their appearance, deep processing and stability. Therefore, decolorization is required in the refining process of edible fats and oils.

The commonly used decolorization method in oil and fat processing is adsorption decolorization method, which makes use of the selective adsorption effect of certain substances (decolorizers) on some pigments to remove the pigments and other impurities in the oils and fats. Commonly used decolorants are activated white clay, bumpy clay, activated carbon, zeolite, acidified rice husk ash, carbonized bean husk ash, etc. Among them, the most widely used is activated white clay.

- Activated white earth is natural bleached earth acidified by strong inorganic acid, and the activity degree is greatly improved. It has strong adsorption capacity for chlorophyll and other colloidal substances, and has stronger adsorption capacity for alkaline and polar atom groups. But at the same time, the activated white clay also has oil absorption, after decolorization and filtration of waste white clay containing 25% to 40% oil, and, due to the high activity, will make contact with the activated white clay oil and grease partially hydrolysis, resulting in the decolorization of oil and grease acid price increases. Research shows that adding 1% of activated white clay can increase the acid value (KOH) of decolorized oil by 0.01mg/g.

In the decolorization process, the addition amount of active white earth is generally 1% to 7% of the weight of the oil. White earth dosage is too small, can not achieve the expected decolorization effect; white earth dosage is too much, will lead to increased damage to the oil, decolorized oil acid value back to the rise, peroxide value increases and with too strong white earth flavor, so that the subsequent oil deodorization section of the difficulty of the process. Therefore, one of the biggest problems in the decolorization process of activated white clay is how to further reduce the use of white clay and improve the decolorization rate under the condition of guaranteeing the decolorization effect.

To address this issue, researchers in oil and grease engineering technology have been exploring, proposed a variety of methods, such as: activated white earth mixed with other decolorants; the activated white earth to improve; the decolorization process and equipment to improve, have achieved certain results. The author introduced the two filter aids, diatomaceous earth and perlite, and analyzed their application in the decolorization process of activated white earth to make a foundation for further research.

Characteristics and application of filter aids

Filter aid is a hard and finely crushed to varying degrees of auxiliary powder granular material, can form a loose structure of the filter cake, and in the operating pressure range is almost incompressible, can reduce the resistance of the cake or filter media resistance. Filter aids used in the food industry must be inert and non-toxic, can not contain organic and inorganic substances that can be dissolved by the filtrate and microorganisms, to the filtrate of the color and flavor of the small impact. Oils and fats decolorization process commonly used filter aids are diatomaceous earth and perlite.

1、Diatomaceous earth filter aid

Natural diatomaceous earth is a single-cell aquatic plants after the death of the silicate remains of the sediment, the main chemical composition of which is silica, and a small number of impurities. Diatomaceous earth filter aid is based on the need to select a certain quality of diatomaceous earth, through the acidification process, add other additives and other processes, and then after drying or calcination and made of a class of powdery substances.

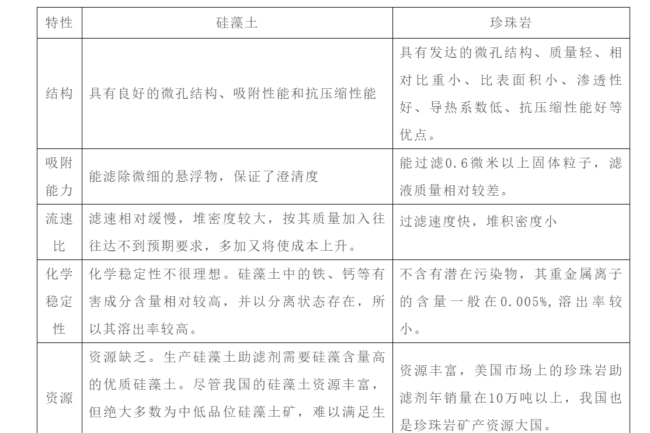

Diatomaceous earth filter aid is a powdery product composed of discs, tubes and irregularly shaped particles, which have unique microporous structure, different particle size distribution, large specific surface area and stable chemical properties, so that the liquid to be filtered to obtain a high flow rate ratio, and can filter out fine suspended solids, and the smallest impurity particles can be retained from 0.1 to 1um.

The cake layer formed by diatomaceous earth filter aid has a high degree of permeability and adsorption, thus improving the interception accuracy and processing capacity. Applied research shows that diatomaceous earth filter aid filtration can remove solid particles, suspended matter, colloidal particles, bacteria and viruses, etc., and its filtration effect is mainly the mechanical retention and adsorption of impurities. Diatomaceous earth filter aid has been widely used in food brewing, medicine, petroleum, chemical industry and water treatment and other sectors, the main application areas are beer, medicine (for antibiotics, plasma, vitamins, synthetic pharmaceuticals, injection filtration), water filtration, oil and grease industry, organic solutions, paints and dyes, fertilizers, acids, alkalis, spices, sugar, alcohol and so on.

2.Perlite filter aid

Perlite is a kind of acidic siliceous volcanic glass lava containing crystalline water, the main chemical composition of which is SiO2, and a small amount of potassium oxide, sodium oxide, magnesium oxide, calcium oxide, aluminum oxide and organic impurities. Perlite filter aid is a certain quality of perlite raw materials, high-temperature calcination treatment, so that the crystalline water evaporation, the volume of rapid expansion, the formation of expanded perlite, and then after grinding and screening.

Perlite filter aid is a white solid powder, consisting of very irregular curly-coiled flaky particles, characterized by light weight, small specific gravity, small specific surface area, good permeability, low thermal conductivity and good chemical stability. It can be used for food grade filtration because it does not contain potential contaminants, and its heavy metal ion content is generally 0.005%. The porosity of the formed filter cake is 80% to 90%, there are a large number of capillary pores between the particles, in the filtrate long-term stable and rapid filtration at the same time, it can retain particles of 0.6 micron or more, and play the role of adsorption of impurities, clarification of the filtrate. Perlite filter aid is widely used in petroleum, chemical, pharmaceutical, food and beverage and sewage treatment industries.

Application of filter aid in the decolorization process of edible oil

1、Method of operation

Filter aids are usually used in three ways: pre-coating filtration, slurry filtration and pre-coating and slurry filtration.

(1) Pre-coating filtration

Pre-measured filter aids and the right amount of clean water or slurry in the charging barrel mixed into a suspension, and then pre-coating cycle. When the filtrate clarification degree reaches the requirements, the slurry can be filtered. At this time, the pre-coating directly play the role of medium, this method is generally applicable to deep filtration. The thickness of the filter bed is generally 3 ~ 80 mm.

(2) Filtration with slurry

Mix the slurry and filter aid first, and then pass the filter for filtration. Filter aids and solids in the slurry accumulate together on the surface of the filter layer to form a filter layer, so that filtration can maintain a relatively stable filtration rate. At this time, the addition of filter aids, its particle size is only determined by the various characteristics of the solids in the slurry, but not affected by the form of the filter.

(3) Pre-coating and dosing filtration

Pre-coating and adding two steps: the thickness of the pre-coating is generally 2 ~ 3 mm, its main role is to protect the filter material from contamination, and to ensure that the filtrate can be clarified at the moment of filtration into the addition of filtration. The thickness and structure of the pre-coating are particularly important in the whole filtration process. After the completion of the pre-coating, to be filtered slurry into the filter, need to be added at the same time the weight of the slurry 0.1% to 2.0% of the filter aid. In the filtration process, the filter aid and the impurity particles floating in the slurry to form a loose porous cake to maintain an economic filtration rate. Add the amount of how much depends on the number of particles of impurities and their compressibility, compression rate of impurities, filter aids to add a corresponding increase.

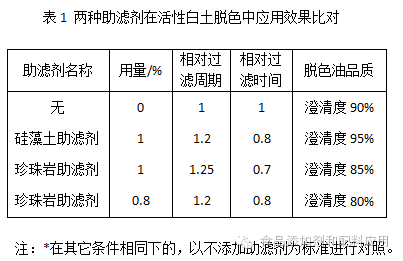

For the filter press, the ideal additive amount should be when the filtration pressure reaches the rated pressure, the formation of the cake is basically filled with the allowable residue space of the filter press, so that a filtration cycle is completed and the filter press enters the cleaning stage. In this study, the method of slurry filtration was adopted, firstly, the purchased diatomite filter aid and perlite filter aid were mixed with activated white clay according to a certain proportion, and then they were applied to the section of decolorization of edible oil, and then filtrated by the conventional process, and the related parameters were recorded, and the effects of the two kinds of filter aids were compared (Table 1).

The study shows that both filter aids can increase the filtration speed and prolong the filtration cycle of the filter cake when applied in the decolorization of activated white clay. Among them, the effect of perlite filter aid in improving the filtration speed and prolonging the filtration cycle of the filter cake is better than that of diatomaceous earth filter aid, but due to the difference in the composition of the particles, the adsorption effect of diatomaceous earth filter aid is better, and the decolourized oil after filtration is more clarified.

Conclusion

(1) Filter aid also has a certain adsorption effect, adding filter aid can appropriately reduce the amount of activated autoclave.

(2) Adding filter aid can improve the decolorization and filtration speed of activated white clay well, so as to improve the product quality.

(3) The effect of perlite filter aid in enhancing the filtration speed and prolonging the filtration cycle of the filter cake is relatively better than that of diatomaceous earth filter aid, but the adsorption effect of diatomaceous earth filter aid is better, and the decolorized oil should be more clarified after filtration.

(4) We can try to mix perlite filter aid and diatomaceous earth filter aid according to a certain ratio to complement each other’s advantages, and improve the filtration speed and quality of filtered oil within the range of cost.