Do you know all 4 caramel colors?

Caramel pigment, also known as caramel or sauce color, is a class of dark brown liquid, powder or granule with caramel flavor. It is made by the caramelization of carbohydrates under certain conditions or Meladic reaction with amino compounds, because of its good water solubility, strong coloring rate, high stability, safety and non-toxicity, etc., it is widely used in condiments, beverages, baking and other food industries. For example, the unique brown color of cola drinks and the color of soy sauce come from caramel pigment.

In practical use, according to the physical and chemical properties of caramel and the characteristics of the food itself should be selected according to the physical and chemical properties of caramel, in order to obtain stable nature, good sensory quality of food.

Physicochemical properties and product index of caramel pigment

1.1 Color rate and red index of caramel pigment as a coloring agent, color rate is an important indicator, the provisions of the 0.1% caramel solution (W/V) using precision spectrophotometer at a wavelength of 610nm, through the 1cm cuvette to determine the optical density, and then through the formula converted to the rate of excellence (unit EBC). The greater the optical density, the stronger the coloring power is indicated;

The red index is a characteristic index of optical density measured at wavelengths of 510nm and 610nm, which determines the colorfulness of caramel pigments. The higher the red index, the higher the proportion of red components in the caramel pigment. 1.2 Baume degrees and viscosity Baume degrees reflect the content of liquid caramel pigment solids, viscosity reflects its viscosity and adhesion. The product has strong adhesion and can be applied to soy sauce to make its body thick and hang well. 1.3 Salt water precipitation in a certain concentration of salt solution, dissolve the appropriate amount of caramel pigment, and then centrifuged by centrifuge to determine the salt resistance of the caramel pigment. This index reflects the colloidal stability of the caramel pigment to a certain extent, and the brine precipitation index is particularly important for the caramel pigment used in soy sauce. 1.4 pH value This indicator is very important when applied to the product, because pH value affects the affinity of the product and other ingredients. Generally speaking, the pH value of brewing caramel coloring added to soy sauce, vinegar and fermented wine is in the range of 3.8-5.5, while the pH value of caramel coloring added to carbonated beverages and fruit juices is in the range of 2.5-3.5. 1.5 Charge caramel coloring has colloidal properties, generally due to different production processes and make the colloid with a different charge. Brewing caramel pigment colloid adsorption of cations, so positively charged; acid-resistant caramel pigment colloid adsorption of anions, so negatively charged.

Brewing caramel coloring is positively charged and is mainly used in the brewing industry, while double caramel coloring is negatively charged and is mainly used in the soft drink industry. The pH and charge properties of caramel colorants are very important indicators in various applications.

Due to the mutual attraction of dissimilar charges, they cause precipitation or turbidity. Generally speaking, the PH value of caramel coloring added to beverages is between 2.5-3.5, with a negative charge, because beverages are negatively charged, making them repel each other with the same kind of charge, and the PH value of caramel coloring added to soy sauce is between 3.8-5, with a positive charge.

Classification of caramel coloring

2.1 Classification according to product model According to the different product models can be roughly divided into caramel into ordinary single type, ordinary double type, brewing type, old red type and special red.

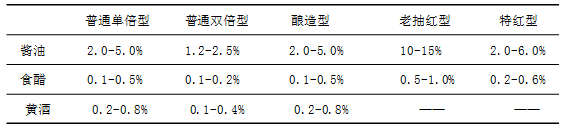

Table 1 Properties of different types of caramel

2.2 Classification according to the type of catalyst used in production The International Technical Caramel Association (ITCA) classifies caramels into ordinary caramels (without catalyst), sulphite caramels (with sulphite as the catalyst), ammonia caramels (with ammonia as the catalyst) and ammonium sulphite caramels (with ammonium sulphite as the catalyst) according to the different catalysts added to caramels during production, and their properties are summarized in Table 2.

Table 2 Properties of different categories of caramels

2.3 Grade Classification of Caramel Colors According to different catalysts used in caramel production, caramel colors can be classified into 4 grades, and different grades of caramel colors are adapted to different foods and beverages.

Grade Ⅰ caramel, also known as clear white caramel, does not contain components such as ammonia or sulfites, and the colloid is negatively charged, which is suitable to be used in high alcoholic beverages with less than 75% concentration.

Grade II caramels, which are caramels treated with sulfites, are limited to use in food and beverages. Gummies carry loads. Grade III caramels, which are caramels produced by the ammonia process, are colloidal with a negative charge, highly colored, and stable at pH 3. It can be dissolved in 20% concentration of salt solution and is suitable for use in a variety of soups, sauces, beer, barley wine, bread, cookies, and canned foods.

Grade III caramels or Grade IV caramels are well dispersed in water and raw dough and are very suitable for use in baked goods.

Grade IV caramels, which are co-processed by the ammonia and sulfite methods, have an extremely strong color and negatively charged colloids, and are generally used in cola beverages and other soft drinks. Negatively charged caramel colloids are used with low pH isoelectric point beverages to avoid flocculation or precipitation of beverages (the pH of refreshing beverages is generally 2.5~3.5).

Caramel pigmentCaramel pigment test items

Chromaticity: visual inspection and colorimeter are available. Nowadays, it is generally measured by spectrophotometer, and the FCC defines color intensity as the absorbance of one-thousandth concentration of caramel pigment (solvent is distilled water) placed in a 1-cm-thick colorimetric cup when 610 millimicrowave-long light passes through the spectrophotometer.

Specific gravity: determined using a liquid hydrometer or densitometer.

Percent solids: determined using the AOAC method or a hydrometer and approximated by looking up a sugar table.

pH: Measured by glass electrode or pH meter. For soft drinks caramel coloring pH 2.5 ~ 3.5, other applications of liquid caramel coloring pH greater than 5, some powdered gum sugar coloring pH will be greater than 8.0.

Viscosity: Measured with a viscometer at 20°C, accurate to 1 centipoise.

Fogging point: the fogging point is an indicator of the resistance of the caramel coloring to concentrated phosphoric acid. 1 part of the acid is added to 2 parts of caramel, mixed, and heated in a boiling water bath. A drop is taken every 5 minutes into a test tube of distilled water and the clarity of the solution is observed. The time at which the solution appears cloudy from the drops of caramel is the fogging point.

Gelation point: The gelation point is an extension of the fogging point. It is the time required for the acid to stop flowing after mixing with the caramel.

Resinification: Both the shelf life of the caramel and an important indicator. The test for resination gives how long the caramel can remain free-flowing. A small amount of caramel is taken and sealed in an ampoule and kept at 100°C. The caramel is then stored in the ampoule at 100°C. The caramel is then stored at 100°C. The time required when the sample in the ampoule no longer flows is the resinization value of that caramel.

Ash: The percentage of the total caramel that remains after burning.

Isoelectric point: The isoelectric point is the pH at which the colloidal charge of the caramel pigment is neutral. It is determined by the composition and processing of the caramel coloring. Negatively charged caramel coloring has a higher pH than its isoelectric point. The method of determining this neutral point is based on the attraction of oppositely charged particles to each other. The procedure is generally to select a solution with a known colloidal charge and determine its pH at which the charge of the caramel coloring’s particles changes. Because soft drink concentrates require negatively charged caramel pigments, it is recommended that the caramel color have an isoelectric point of pH 1.5 or lower.

Brewing Caramel Usage and Attention

In the use of brewing caramel coloring, we believe that it can be divided into two categories. One category is fermented type and the other is prepared type. When is it good to add caramel coloring in fermented soy sauce. According to our understanding, during the fermentation process, when the amino acid nitrogen reaches the highest value, fermentation is immediately interrupted and caramel coloring is added. It makes up for the short fermentation period that affects the color. It not only ensures no loss of nutrients, but also achieves the purpose of color adjustment.

For prepared soy sauce, there are no strict requirements for the addition of caramel coloring. Only the required ingredients are adjusted, and then the caramel coloring is added. It doesn’t matter what you mix now and what you mix later. Just pay attention to hygiene. In addition, in the use of the process need to pay attention to the use of caramel coloring and the production of products and whether or not; packaging must be used up after opening the lid, easy to be contaminated for repeated use; before use, should pay attention to the re-temperature can not be more than 60 ° C (should not be heated over an open flame); stacking should be in the cool ventilated place; in the application, it should be made with the product affinity, stability experiments. Meanwhile measure the dosage and cost. Another thing that must be noted is the equipment, apparatus, and environmental hygiene used in the production of soy sauce to avoid product quality accidents caused by pollution. In the use of caramel pigment, in addition to understanding the nature of its charge, but also must pay attention to its pH value. Because the caramel pigment charge and pH value can be applied with the product is an important factor of harmonious coexistence. If the mutual charge is different, it is easy to make the product turbid or flocculation and precipitation.

Problems and solutions encountered in the application

Question 1: Is it safe to add caramel coloring to food? What are the relevant standards? At present, according to the relevant provisions of GB 2760-2014 “National Standard for Food Safety, Standard for the Use of Food Additives”, four kinds of caramel color (produced by adding ammonia), caramel color (caustic sulfate), caramel color (common method) and caramel color (ammonium sulfite method) are used as coloring agents, and the corresponding scope and limit of use in foodstuffs are stipulated for different production methods. For example, the amount of caramel color produced by ammonia method in the preparation of condensed milk, frozen drinks, jams and other food products cannot exceed the maximum limit; caustic caramel color can be used in brandy, whisky, rum and prepared wines, and the maximum use limit is 6.0 g/L.

Caramel color produced by common method has the maximum use limit in jam, rum, whisky and puffed food; caramel color produced by ammonium sulfite method has the maximum use limit in many kinds of food, such as prepared condensed milk, frozen drinks and cookies. For caramel color, there is also a corresponding national product safety standard, namely GB 1886.64-2015 (National Standard for Food Safety, Food Additives, Caramel Color). The standard limits the content of 4-methylimidazole in caramel color products produced by ammonium sulfite method and ammonia method, i.e., not exceeding 200 units, and provides corresponding testing methods. Therefore, production according to the standard can ensure the safety of caramel color added food. Question 2: Why do some companies have the feeling of “thinness” in the use of acid-resistant double caramel color, is there any quality problem? Is there any quality problem? Will it increase the usage amount? A: The quality level of acid-resistant double caramel pigment is not determined by feeling, but by whether the indicators of caramel are in accordance with product standards. The dosage of double caramel is mainly determined by the color rate indicator, the color rate is 1 gram of caramel in 1 liter of water coloring power, the detection of this indicator are measured using very precise instruments, the error is less than one thousandth. Therefore, the amount of double caramel pigment used is not determined by the “consistency” or “thinness” of the caramel, but by the product’s quality indicator “color rate”. The “thinness” of the double caramel coloring purchased by the user is mainly due to the low viscosity of the product. Double caramel coloring with low viscosity not only dissolves quickly in use, but also has a shelf life of more than 2 years. And the consistency of large (i.e., viscosity) double caramel pigment dissolves slowly, but also in the shelf life of the production of lipid (i.e., the production of lumps, does not flow, insoluble in water and other phenomena) phenomena, to the user caused by the loss.

Therefore, under the condition that the product meets the color rate and other indexes, the double caramel pigment with the sense of “thinness” is a good product, and the customer will not increase the dosage in the dosage. Important note: The lower the viscosity of the acid-resistant double caramel pigment, the better, to ensure the quality of the user’s products to the maximum extent possible. Question 3: What is Acid Resistant Double Caramel Pigment? What is the difference between it and acid-resistant double caramel pigment? A: Caramel pigments are generally classified into four categories according to different production processes: acid-resistant caramel pigments; ammonia-type caramel pigments; normal caramel pigments and caustic sulfite caramel pigments. Both single and double caramel pigments belong to the first category of acid-resistant caramel pigments, which are negatively charged. However, due to the production process, formula, catalyst dosage is different and in the color rate, hue, viscosity, specific gravity and other aspects are different. Generally, the color rate of double caramel pigment is more than one times of single caramel pigment, but the hue (i.e. red index) is lower than single, and the viscosity and specific gravity are also smaller than single. Double caramel pigments are generally used in acidic beverages and other negatively charged liquid beverages or in bakery and condiments. Single caramel pigment is mainly used in the production of acidic beverages or bakery products with high color requirements (large red index). For example, in the production of tea drinks, sarsaparilla and some liquid health products. Question 4: Why is there precipitation when using caramel coloring in some products? How to solve it? A: Caramel pigments have different charges due to different production processes. Acid-resistant single, double and powder (when dissolved in water) caramel colors have a negative charge, while ammonia-based brewing caramel colors have a positive charge. Therefore, when using these two types of caramel coloring must pay attention to the pH value or what charge is added to the ingredients. Such as containing protein, amino acids more beer, wine, wine, rice wine and soy sauce, vinegar and other liquids with a positive charge, to color these products generally use ammonia-type brewing caramel pigment.

The production of acidic beverages such as cola-type beverages, tea drinks, plum drinks, sarsaparilla soda, etc., the coloring is generally used to acid-resistant type single, double and powdered caramel pigments. And some products such as fermented wine, prepared wine, cherry wine, etc. Because the protein and amino acid in the product has been basically removed in the production process, plus itself with acidity, so the acid-resistant single and double caramel coloring will not produce precipitation. Solution: It is suggested that when the users are not clear about the charge of the products they need to color, they should add these two types of caramel pigments with different charges into the products to do experiments, and the results of precipitation or no precipitation will generally be observed within 24 hours. Of course, if the cause of product precipitation is not due to the addition of caramel pigment, then the user needs to make other precipitation experiments to find out the cause of product precipitation, so that the problem can be solved.

Application of caramel coloring in condiments

Caramel pigment produced by common method is suitable for soy sauce, vinegar, seasoning sauce, seasoning powder and sauce; caramel pigment produced by ammonia method is suitable for soy sauce and vinegar. The caramel coloring used in condiments is mainly produced by ammonia method. Condiments generally have a high salt content (e.g. soy sauce), and most of them are acidic, some of them are more acidic (e.g. vinegar), so it is necessary to choose suitable varieties in use.

The caramel color used in soy sauce must be salt-resistant, otherwise it is very easy to precipitate; and in order to improve the red brightness and wall-hanging of soy sauce, it is necessary to choose varieties with high red index and solid content. Caramel pigments used in vinegar are generally acid-resistant, otherwise they will fade in a short period of time.

Since the color rate of brewing caramel pigment is similar to the color rate of single caramel pigment, some manufacturers also call brewing caramel pigment as single caramel pigment. However, this is a product conceptual error, because brewing caramel pigment with a positive charge, mainly used for soy sauce, vinegar and other brewing condiments coloring, such as its use in acidic beverages will generally produce precipitation. Similarly, the use of negatively charged acid-resistant single or double caramel colors in products such as soy sauce may also produce precipitation. Table 3 Amounts of different types of caramel colorants used in flavorings

Caramel pigment development prospects

For the current situation of caramel, the development trend it presents has the following points: More diversified products and wider application range. At present, according to the different types of catalysts in the production process caramel is divided into 4 kinds, the variety of products is limited, in the future, with the advancement of new production technology and the application of new catalysts, the varieties of caramel will be richer, to adapt to the needs of more food. The industry is more standardized and scaled. With the soundness of the national regulatory system, small and medium-sized factories will face a new round of elimination, and the ones that survive under the fierce competition will be the ones with strong anti-risk ability and guaranteed product quality. Safer and greener products. Due to the improvement of people’s living standards, more and more people are pursuing a healthier and greener diet, which will certainly promote the use of caramel in the production process of greener raw materials and processing technology has become a development trend.