What are the common models and application cases of food shelf life prediction?

The shelf life of food not only affects the sensory enjoyment of consumers, but also concerns the health and safety of consumers, and is related to the reputation, brand and economic benefits of food manufacturers. Accurately predicting and calculating the shelf life of products under specified storage conditions is the guarantee and commitment of manufacturers to the quality and efficacy of food during the circulation period, which can provide an effective basis for the formulation of product storage, circulation and distribution strategies, and can also provide a reference for the possibility of further extending the shelf life.

The shelf life of a food is the period during which the quality of the food is maintained under the indicated storage conditions, usually the period of time during which the food is acceptable for consumption in terms of physical, chemical, microbiological or sensory properties. There are two possible scenarios depending on the product characteristics.

The first is the “safe consumption period”, mainly for perishable food, after the “safe consumption period”, it is likely to pose a direct threat to human health in a short period of time, the food is considered unsafe, can not be sold or eaten;

The second case is the “best before”, the date when the food retains its specific characteristics (including quality characteristics such as appearance, smell, texture, taste, etc.) when properly stored (EU1169/2011).

At present, the standard term used in China is “food shelf life”, and in Article 15 (3) of the “Food Labeling Supervision and Administration Measures (Draft for Comments)” issued on September 23, 2020, “the quality date can be marked by” eating (drinking) before ××× month ×× day of ××× Year ×× month ×× day of ××× year ×× “, etc.” Indicates that the future “food shelf life” will include the concept of food shelf life.

This paper will focus on the relevant standards and regulations of food shelf life, summarize the shelf life prediction method based on the principle of quality decay, and analyze the problems existing in the practical application of the existing shelf life prediction model combined with the previous research basis, in order to provide a certain basis for food manufacturers to evaluate, design and verify the food shelf life.

Status of food shelf-life/use-by standards and regulations

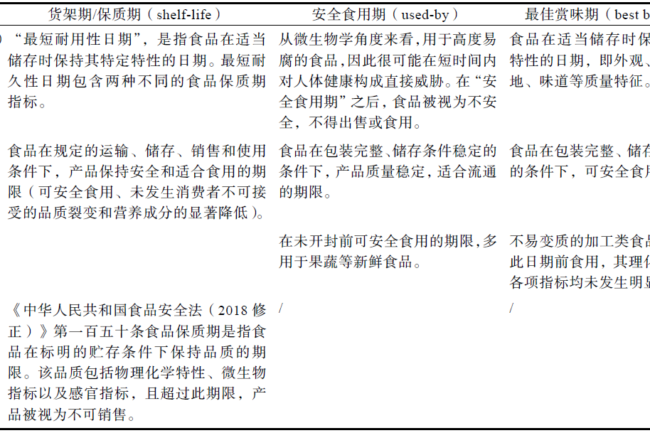

At present, there is no universal standard for the definition of food shelf life or shelf life of food in various countries. ISO 16779:2015 stipulates that the best before date of food is the deadline for the marketed products to maintain their declared quality under specified storage conditions, that is, before this date, the product quality is still completely satisfactory; And the use-by date is the expiration date by which the safe quality of the food is maintained under specified storage conditions, after which the product may not have the quality attributes commonly expected by consumers, that is, after this date, the food should not be considered marketable.

Table 1 Food shelf life/shelf-life standards and regulations in different countries

Common models and applications of food shelf-life prediction

The shelf life currently labeled on food and beverage products generally provides consumers with a rough guide to the shelf life of the product under established processing, packaging, transportation and storage conditions.

However, in the actual product life chain, changes in storage conditions, damage to packaging by transportation and other factors may make the actual shelf life of the product shorter or longer than the intended shelf life of the product, resulting in problems related to food safety and waste.

Advances in shelf-life prediction and assessment are therefore critical to improving the safety, reliability and sustainability of the food supply.

In the shelf life prediction method, it is crucial to choose the right dynamic model and data analysis technology, which can predict the service life of the product more accurately according to the change of environmental conditions, and can also be monitored in real time. In this paper, the method of shelf life prediction based on quality decay principle is reviewed.

In recent years, domestic and foreign scholars have used dynamic models to study the quality changes of meat products, vegetables, fruits and so on, and predicted their storage life, and achieved good results.

By analyzing the main factors that affect the change of product quality, the key indicators for the end of shelf life are determined, and the shelf life prediction method system based on the principle of quality decay is formed.

The change of food quality is determined by internal quality property factors Ci (such as concentration, pH, water activity, etc.) and external environmental factors Ej (such as temperature, relative humidity, packaging, etc.). Food quality decay can be expressed as: rQ=f(Ci,Ej). Food quality decay generally includes chemical quality decay, microbial growth dynamics and food sensory failure.

1. Chemical quality decay kinetics model Food deterioration is mostly caused by chemical reactions, the chemical quality decay kinetics model is generally used to predict shelf life.

The commonly used kinetic model of chemical mass decay is the Arrhenius model.

Arrhenius model is applied to food which is easily destroyed by chemical reaction, such as fat oxidation, Maillard reaction and protein denaturation.

In general, the higher the temperature, the faster the speed of chemical reaction, which means the faster the product quality decline. The Q10 model focuses on the influence of temperature on the shelf life, which leads to low prediction accuracy. In the Arrhenius model, the concept of Q10 is used to determine the sensitivity of temperature to reaction.

The loss of shelf life of A food is usually assessed by measuring the change in the characteristic mass index A over time t, usually expressed as f(A)=k(T)t, where f(A) is the mass function of the food and k is the reaction rate constant.

The rate constant is the inverse exponential function of the absolute temperature T, given by the Arrhenius Arrhenius expression, k=kAexp(-ea /RT), where kA is a constant, EA is the activation energy of the reaction controlling mass loss, and R is the universal gas constant. According to the following fitting equation, the product quality at the end of the shelf can be calculated: -d [A]/dt=k[A]n, -d [B]/dt=k ‘[B]n’, where k and k ‘are the quality change rate constants; n and n ‘are the order of reaction; d[A]/dt and d/dt are quality change rates. Loss of chemical index A (such as nutrients or characteristic flavors) or undesired chemical index B (odor composition or fading pigment content) is zero-order mode if A linear fit of A or B to time t is satisfied; If the linear fit between A or B semilogms and t is satisfied, it is a first-order model. If A linear fit of 1/A or 1/B to t is satisfied, it is a second-level mode.

Microbial decay is one of the main ways food deteriorates, especially for fresh or minimally processed refrigerated products.

Microorganisms can cause food spoilage or cause foodborne illness. Studies have shown that food spoilage caused by microorganisms is mainly caused by the activities of specific spoilage organisms (SSO) in food storage, and the microbial flora is not static, and changes with the internal factors and external environmental factors of different types of food. Its growth trend is an important factor in predicting food shelf life.

Shelf life can be defined as the time from the start of storage until SSOs reach a certain maximum level. Production and processing enterprises should conduct shelf life tests to determine when deterioration occurs, and should effectively verify the growth trend of pathogenic microorganisms, using sound scientific research to assess the potential risk of their food.

There are many temperature-related models in the literature to describe microbial growth and a range of software tools have been developed to predict the growth of certain microorganisms in food, however only a few are applicable to actual shelf life prediction.

There are four common first-order models of microbial dynamics: Linear model, Logistic model, Gompertz model and Baranyi & Roberts model. Gompertz model is the cornerstone of predictive microbiology. The PMP (Pathogen Modeling Program) system developed by the US Department of Agriculture and the Food Micromodel (FM) system developed by the UK Department of Agriculture, Food and Fisheries both use Gompertz function as the primary model.

3. Sensory Predictive shelf life models Sensory Predictive shelf life methods As early as the 1980s and 1990s, Taoukis et al. described the principles and methods for performing effective Accelerated shelf-life testing (ASLT).

In the ASLT method, temperature is the key parameter in determining food damage, because the higher the temperature, the faster the food damage.

The relationship between temperature and the rate of deterioration can be expressed by the Arrhenius equation. There are generally two main classes of tests that can be used for this purpose: differential tests (especially pin-wise comparisons, double-triplet tests – usually in controlled tests for variation in differences – and triangle tests) and tests that use appropriate scales (features or some specific attribute).

At present, the widely used sensory shelf-life prediction method at home and abroad is Weibull hazard analysis, which is a practical method, effectively combining the principle of ASLT and sensory methods and making improvements.

Weibull probability function is widely used to describe failure phenomena in engineering, and it was proposed by Gacula and Kubala for shelf life testing. The principle of the method is that the relationship between the cumulative harm rate and storage time reflected by the rejection of the product by the consumer is as follows: lgt=lgH/β+ LG-α : t is the time /d of discovering the new spoiled food; H is the cumulative risk rate /%; α is the scale Weibull distribution parameter; Beta is the shape Weibull distribution parameter.

Wahyuni et al. studied the prediction of the shelf life of brownie cakes by adopting the accelerated shelf life testing (ASLT) method combined with the Arrhenius model.

In this study, three storage temperature changes of 20℃, 30℃ and 40 ℃ were used, and thiobarbituric acid (TBA) was selected as the change index for monitoring.

According to Ketaren’s research, changes in nutrients such as fat during storage will cause food rancidity, and the oxidation products aldehydes can form colored compounds with TBA. The TBA value is used to indicate the degree of oxidation, and the amount of TBA is the most important factor in determining the degree of oil damage.

The experimental results showed that the TBA value increased with the increase of storage temperature, and the storage life of brownie was estimated by Arrhenius equation, that is, with the increase of temperature (20℃, 30℃, 40 ℃), the product shelf life was 1.57, 4.9 and 14 days, respectively.

Nashi et al. conducted a shelf life study on the flavor characteristics of oat grain beverages after instantaneous ultra-high temperature treatment, and the evaluation indexes included adverse flavor mixture, n-hexal and PVG. The evaluation method adopted flavor substance chromatography, and a sensory evaluation team was set up to score the flavor acceptability. The experimental results showed that when the n-hexal content was 3-5 times higher than the initial value, the flavor quality of oat grain beverage was improved. Oatmeal cereal beverage flavor is unacceptable.

HU et al. studied the quality changes and shelf life of eggs embedded with chitosan during storage, and measured the quality changes of eggs embedded during storage at 5℃, 20℃ and 35 ℃ respectively. The Pearson correlation coefficient of Hough value, density and percentage increase of chamber diameter was analyzed to establish a shelf life prediction model based on Arrhenius equation.

The results showed that the quality of eggs decreased with the extension of storage time. High temperature (20℃ and 35 ℃) storage environment than low temperature (5 ℃) storage environment has a significant effect on quality deterioration. The correlation coefficient between egg yolk quality and Hough unit is the highest, which can be used as an important index to predict shelf life. According to the variation law of egg quality, the first-order dynamic model of egg yolk can be established.

The coefficient R2 of the curve fitting between the predicted value and the measured value was 0.982 5, and the average relative error P was 9.32%, less than 10%. The dynamic relationship between egg yolk quality and temperature was described.

At the same time, based on the dynamic model, the shelf life prediction model of chitosan egg based on egg yolk coefficient was determined. The average relative error is 7.6%, less than 10%, indicating that the egg shelf life prediction model based on yolk quality change is feasible.

Liu Hong et al. showed that at present, the determination of shelf life in China’s food and beverage industry mostly relies on reference method, that is, empirical value to determine, and lacks scientific and standard test methods. Q10 model is a widely used method for accelerating destructive tests in China, which mainly studies the effect of temperature on product quality during storage.

Ren Yani et al. used ASLT method to predict the shelf life of soft bread. The experimental temperatures were set at normal temperature of 20℃, 37℃ and 47 ℃, and the relative humidity was 60%. By testing the acid value, peroxide value and microbial indexes (total number of colonies, mold and Escherichia coli) of the products at 37℃ and 47 ℃, combined with the sensory evaluation results and the Q10 model, the authors analyzed the results of the tests. The shelf life of soft bread is calculated under normal temperature storage condition.

In recent years, some kinetic models and microbial growth models have been gradually applied to product shelf life prediction in China. Hu Yunfeng et al. studied the dynamic model of quality change of fresh and wet rice flour at different storage temperatures, and applied the Arrhenius model to predict its shelf life. The results show that the fitting coefficient of the classical blue value of fresh and wet rice flour is high, and the model based on the classical blue value as the prediction target has a small empirical error.

Cheng Xiaofeng et al. studied the shelf life prediction of compressed biscuits and selected ASLT method combined with Arrhenius model for prediction. Under the condition of accelerated storage temperature, the change of acid value of compressed biscuits was determined. It was found that the change of acid value was obvious, which was in line with the first-order kinetic model. The shelf life prediction equation of compressed biscuits was established, and the shelf life of products at 45 ℃ was calculated.

Problems and suggestions in the study of shelf life in China

1. The current shelf life research covers few types of products, mostly ready-to-eat foods;

2. Many types of domestic products in the current standards lack the design of product quality, especially non-food safety indicators (health indicators), but in the actual circulation of commodities, product quality often changes before food safety indicators, resulting in difficult to determine the end of product shelf life.

For example, when carrying out the shelf-life experiment of nut bar products, the experimental scheme of nut bar products was designed by referring to the shelf-life stability experimental scheme based on temperature conditions in Appendix B of T/CNFIA 001-2017 General Guide for Food Shelf-Life. According to the reference data, the accelerated experiment was designed according to Q10=4, using room temperature samples (25 ℃), accelerated samples (storage conditions of 35 and 45 ℃, 75%RH) and control samples (storage conditions of 4 ℃). The product was carried out according to GB 7099-2015 “Food Safety National Standard pastry and bread”, according to the relevant requirements of the standard. Physicochemical (acid value, peroxide value), microbiological (total number of colonies, mold number, coliform number), sensory (difference test, consumer acceptance test) indexes were compared and evaluated.

The experimental results showed that under the accelerated conditions of 35℃ and 45 ℃, the acid value and peroxide value did not exceed the standard limit value within 320 days after the conversion of storage days at normal temperature, and the microbial test results were also qualified, which was far lower than the limit requirements in the standard. Therefore, Q10 of the product cannot be determined by acid value or peroxide value test, and the shelf life of the product can be evaluated by acid value or peroxide value.

According to the experimental results of the three-point test of sensory evaluation, in the confidence interval of P≤0.05, the product under the condition of 35 ℃ acceleration had the most obvious difference between the control sample and the product when the storage days reached 270 days at normal temperature, but the control sample had no significant difference, and the difference between the product in continuous storage and the control sample did not expand. When the storage days at room temperature reached 270 d under the accelerated condition of 45 ℃, there was a significant difference between the sample and the control sample. According to this experiment, the shelf life of the product at room temperature should be about 270 d (9 months).

The results of sensory acceptance evaluation showed that under the accelerated condition of 35 ℃, no index failed to meet the minimum acceptance requirement of 3.5 points during the testing period (converted to 320 days of storage at normal temperature). Under the condition of 45 ℃ acceleration, the products with 450 days of storage at room temperature can not reach the minimum acceptance requirement of 3.5 points except the adhesion index. According to this experiment, the shelf life of the product at room temperature should be about 450 days (15 months).

Three different experimental methods have obtained completely different shelf-life test results, and the physical and chemical indicators are not exceeded, the sensory has appeared unacceptable score.

3. For similar grain products (such as rice, noodles, etc.) and other primary processed agricultural products, due to the lack of indicative indicators (physical and chemical, microbial) or indicative indicators of quality deterioration of intermediate products (such as fatty acid value) and the shelf life of the product is poor.

In view of the above problems and many domestic food categories, the shelf life test period is long, and the shelf life prediction data of different categories of food is not strong. It is suggested to increase the research on shelf-life prediction of different food and primary processed agricultural products, strengthen the research on related quality deterioration indicators, and improve the stability and referability of shelf-life prediction data. At the same time, combined with ASLT model, the shelf life is measured after Q10 is obtained through multi-temperature test, and the accuracy of shelf life prediction is improved.