What are the compounding additives?

With the more and more extensive application of compounded food additives in the food industry, food companies for how to standardize the production, use and labeling of compounded additives are also more and more concerned about this article lists some of the use of compounded food additives, labeling and production process of common problems for your reference.

What is compounded food additives

According to GB 26687-2011 “National Standard for Food Safety General Principles for Compounded Food Additives”, compounded food additives refer to food additives made by physically mixing two or more single-species food additives with or without additives in order to improve the quality of food and facilitate food processing.

Special Note: Distinguish between compounded food additives and commercialized single food additives In some single food additives, functional excipients are sometimes added in order to maintain the performance of the additives or to function better, and some of the excipients are also food additives themselves. For example, antioxidants or color protectors are added to colorants to keep the color bright and free from oxidation. Compound food additives and single food additives containing excipients that are themselves additives are not to be confused with each other, although both contain two or more food additives. The standards of use and labeling requirements for both are different.

The main bases for distinguishing compounded food additives from commercialized food additives are: (1) All additives (except excipients) in compounded food additives are required to play a process role in the final product, and are required to have a common permitted food category;

(2) Commercialized food additives, in which other food additives are added to protect this food additive for the purpose of storage, dilution, dispersion, etc. Other food additives are not permitted to play a functional role in the end-use food.

Basic Requirements and Precautions for the Use of Compounded Food Additives

I. Basic Requirements The use of compounded food additives should comply with the requirements of GB 26687-2011 “National Standard for Food Safety General Principles for Compounded Food Additives”, which stipulates the naming principles, basic requirements, sensory requirements, control of harmful substances, labeling and other contents of compounded food additives.

The basic requirements in GB 26687-2011 include: the compounded food additives should not cause any health hazards to the human body; the compounded food additives should minimize the dosage in food while achieving the expected effect; the various food additives used for the production of compounded food additives should comply with the provisions of GB 2760 and the announcements of the national health administrative departments, and have a common scope of use. Compound food additives should not undergo chemical reactions during the production process and should not produce new compounds, etc.

Special Note: Flavorings for food and gum-based confectionery bases are not applicable to the National Standard for Food Safety General Provisions for Compounded Food Additives GB 26687-2011 The scope of application is clear: “This standard applies to all compounded food additives other than flavorings for food and gum-based confectionery bases.” Therefore, for compound food additives, food flavor and gum-based confectionery base agent is not applicable.

Second, the use of precautions (1) the selection of food additives in the choice of a variety of food additive components should have a common scope of use. Such as a compound sweetener, the compound sweetener in each of the main components of acesulfame, sweetener, sodium saccharin, etc., when used in a food, each component must be allowed to be used in the food. If it contains ingredients that are prohibited to be added and used in that food, it shall not be used in that food.

(2) In the process of actual addition and use of compounded food additives, it shall be ensured that the maximum use amount of each food additive complies with the provisions of GB 2760.

(3) The same function of food additives (the same coloring agent, preservatives, antioxidants) in mixed use, the respective amount of its maximum use of the proportion of the sum should not exceed 1. For example, lemon yellow, sunset yellow in the jelly of the maximum amount of use of 0.05g/kg and 0.025g/kg, respectively, the two substances in the jelly at the same time, should meet: lemon yellow/0.05 + Sunset Yellow/0.025≤1. How to identify the compounded food additives in the food ingredient list?

I. How to label each food additive with functional role in the final product in the food ingredient list: GB 7718-2011 Q&A on the labeling requirements of compounded food additives: “Each food additive with functional role in the final product should be labeled one by one in the food ingredient list.”

Labeling method 1: Reflect the attributes of compounding e.g. “Ingredients: pork, starch, compounded moisture retaining agent (sodium tripolyphosphate, sodium pyrophosphate, maltodextrin).”

Labeling mode 2: directly in the list of ingredients separately identified for example: “Ingredients: pork, starch, sodium tripolyphosphate, sodium pyrophosphate, maltodextrin.”

According to the understanding of the relevant standard provisions and the analysis of common marking methods on the market, the above two marking methods are available, have been the compounding of water retention agent with a functional role of each food additive in the food ingredients list one by one, from the authenticity of the ingredients and traceability of the recommended choice of marking method one.

II. Whether the excipients in the compounded food additives need to be labeled in the final product GB 7718-2011 Q&A on the labeling requirements of excipients in food additives: “When the excipients contained in food additives do not play a functional role in the final product, they do not need to be labeled in the ingredient list.”

Excipients in food additives are food raw materials and food additives added for the purpose of processing, storage, standardization, dissolution, and other processes of a single or compounded food additive. These substances are not required to be labeled in the ingredient list when they do not play a role in the food in which the food additive is used. Except for meeting the requirements of the above exemption clause, the excipients in the compounded food additive are sorted and labeled in the food ingredient list according to their added amounts.

Issues Related to Compounding Food Additive License Qualification

I. Compound food additive products are licensed according to product formulations Compound food additive products are licensed according to product formulations, i.e., products with different formulations should apply for licenses separately. With the same single species of food additives and excipients, only its ratio of different compounded food additives can be in accordance with the same formula product license application.

Second, the formula to change or add new formulations should apply for changes in the production license has been granted to the enterprise if the compounding of food additives product formulations to change or add new formulations lead to its no longer comply with the original application to report the implementation of the standards or changes in the category is the need to change the content of the certificate of production license should be in accordance with the “Administrative Measures for Food Production License” to the applicant’s location at or above the county level of local supervision and management of the market Department of change application.

Need to carry out on-site verification of food additives production license can be based on the characteristics of food additive varieties, verification of trial food additives test reports and compound food additive formulations, etc.. Trial food inspection by the producer’s own inspection, or commissioned by a qualified food inspection agency inspection.

Third, the sale of compounded food additives need to apply for a business license “Food Business License Management Measures” in the People’s Republic of China, engaged in the sale of food and food service activities, should be in accordance with the law to obtain food business license. Food additive sales are not food sales and food service activities, and the “food business license management approach” in the food business does not cover food additives, so do not need to obtain a food license.

Hazard analysis of the whole process of compounded food additive production[1]

Taking the application of ISO 22000:2018 food safety management system in the production of compounded food additives (powder) as an example, the whole process of the production of compounded food additives is analyzed for hazards, which mainly include: physical hazards, chemical hazards and biological hazards.

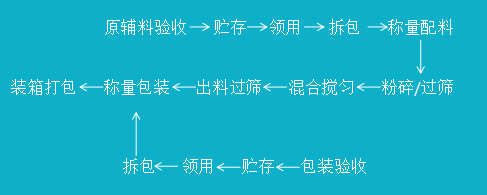

Figure 1 Production process flow diagram of compounded food additives

First, raw materials, packaging materials and equipment and facilities, hazard analysis of raw materials, packaging materials, biological hazards mainly include a variety of pathogenic bacteria, toxins, such as Staphylococcus aureus, Escherichia coli, Salmonella, aflatoxin, etc.; chemical hazards mainly from the raw materials, packages, raw materials, packaging materials, in the process of growth, production, processing and other processes in the environment in the water quality, fertilizers, soil, air, equipment and facilities, raw materials, superior technology defects and other pollution brought about by pesticide residues and heavy metal residues. Pesticide residues and heavy metal residues and other pollution;

Physical hazards mainly include threads, hair, grain shells, leaves, glass fragments, metal wires and other debris. The hazards of equipment and facilities mainly come from the hazards brought in by cleaning and disinfection, repair and maintenance, such as lubricating oil used in equipment may contaminate the food, and foreign matter and parts (such as screws, nuts, etc.) may be mixed into the products if they are not qualified for repair and maintenance.

Second, the production process hazard analysis production process hazards are mainly analyzed from the following aspects: (1) weighing and dosing. Weighing ingredients refers to the process of weighing a variety of raw and auxiliary materials in accordance with the process formula, directly affecting food safety, if not correctly and accurately weighed may lead to the end product of food additives added in excess.

(2) Crushing and sieving. Some raw materials purchased back when the particle size is different, in order to achieve the process of matching the requirements of the raw materials need to be crushed part of the raw materials, and in order to reduce the risk of foreign matter brought into the process as well as to control the particle size of crushed raw materials need to be sieved.

(3) Mixing. The main hazards of this step include insufficient mixing time, incorrect order of feeding, resulting in uneven mixing of the product, and ultimately part of the final product of food additives added in excess.

(4) Sieving. Some of the raw and auxiliary products and in the process of feeding, mixing, etc. may bring in a variety of foreign matter, resulting in physical hazards, so the material should be controlled.

The above is about the compound food additives some common questions and answers, hope can give the relevant food enterprises in the compound food additives production, procurement, inspection, use and labeling to provide assistance, more about the compound food additives, welcome to discuss in the message area. [1] Literature cited: Wang Yuan. Analysis of changes in key provisions of ISO 22000:2018 food safety management system and its application in the production of compounded food additives.