Corn is rich in nutrients, the composition is relatively complete, in addition to rich in calcium, magnesium, selenium, iron, carotene, vitamins and other essential nutrients, but also rich in protein (8%-14%), fat (3.5%-5.7%, of which linoleic acid is up to 60%), and only the content of starch is as high as 64%-78% .

These macromolecules (e.g. starch and protein) contained in corn beverage are a typical thermodynamic unstable system, therefore, in the production process and shelf storage period, it is very easy to occur agglutination and precipitation delamination, so that the turbid and stable state of the corn beverage is lost, which will lead to the reduction of the sensory quality of the beverage.

Most of the modified starches obtained through appropriate modification treatment have many excellent characteristics such as low pasting temperature, high transparency, high viscosity and good stability, small coagulation, good frost resistance, good film-forming properties, as well as acid resistance, alkali resistance and strong mechanical properties.

At present, hydroxypropyl compound modified starch, acetylated modified starch, and hydroxypropyl octenyl succinate starch have been applied in food with more research, but there are few reports on their use in cereal beverages.

In order to better combine the application of modified starch with the processing of cereal beverages, this experiment is intended to select the above three modified starches as stabilizers to be added into corn beverages to improve the stability of corn beverages, so as to provide a theoretical basis and process parameters for the production and processing of corn beverages.

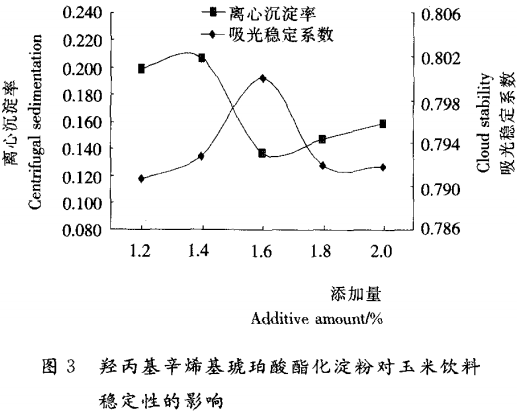

Effect of hydroxypropyl compound modified starch

Effect on the stability of corn beverage

As can be seen from Fig. 1, with the increase of hydroxypropyl modified starch, the light absorption stability of corn beverage increased and then decreased, and the light absorption coefficient was the largest when the amount of hydroxypropyl modified starch was 2.8%; the centrifugal sedimentation firstly decreased and then increased, and the centrifugal sedimentation rate was the smallest when the amount of hydroxypropyl modified starch was 2.8% and the viscosity of the system was moderate.

This may be attributed to the introduction of hydroxypropyl group after the denaturation of starch, which as a functional group hindered the dehydration of starch molecules by intermolecular hydrogen bonding, and kept the modified starch with high viscosity under high temperature, high shear and low pH conditions.

When hydroxypropyl modified starch is applied to corn beverages, it can form network connections with some components (e.g. starch molecules) in corn beverages. The hydroxyl groups gather at the interface and chemically combine with the components in the corn beverage, which enhances the hydration between the components, stabilizes the protein molecules in the network, weakens the hydrogen bonding between the original starch molecules in the corn beverage and blocks the free movement of water, so that the whole system achieves the effect of water fixation and suspension stabilization.

Therefore, the stability of corn beverage was best when 2.8% of hydroxypropyl compound modified starch was added to corn beverage.

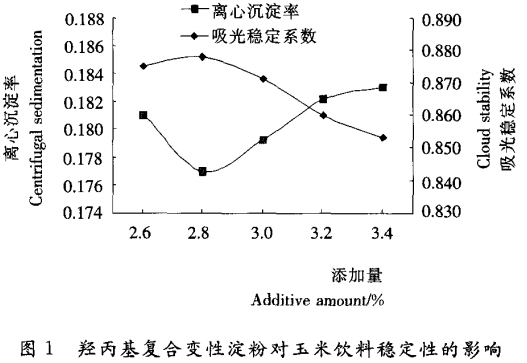

Acetylated modified starch

Effect on the stability of corn beverage

As can be seen in Figure 2, with the increase of the addition of acetylated modified starch, the light absorption stability of the corn beverage firstly increased and then decreased, and reached the maximum when the addition of acetylated modified starch was 2.8; centrifugal precipitation firstly decreased and then increased, and was at a lower level when the addition of acetylated modified starch was 2.8%, and the system viscosity was moderate, and it was in the form of homogeneous turbidity.

This may be due to the acetylated modified starch has good water absorption and hydrophilic ability, in the corn beverage mixing system not only with water molecules, but also with the large molecules in the corn beverage (such as proteins), the combined water with a small particle size uniformly dispersed throughout the mixing system, with the increase in the amount of the addition of the system is gradually stabilized, but when the amount of the addition of 2.8%, the system reached a mesostable state, and the viscosity was uniform turbidity. However, when the addition amount reaches 2.8%, the system reaches a mesostable state, at which time the stability of corn beverage is better.

Therefore, the corn starch with 2.8% of acetylated modified starch has the best stability.

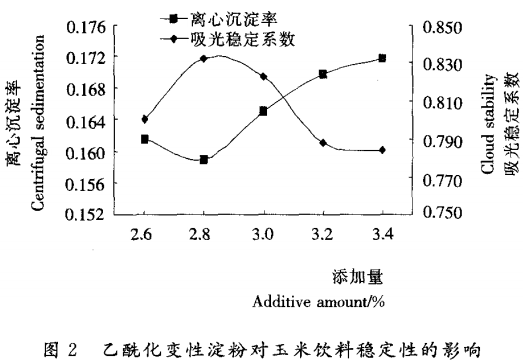

Effect of hydroxypropyl octenyl succinate starch on the stability of corn beverages

Effect on the stability of corn beverage

As can be seen in Figure 3, with the increase of hydroxypropyl octenyl succinate starch, the light absorption stability of the corn beverage firstly increased and then decreased, and reached the peak at 1.6%; while the centrifugal sedimentation rate of the corn beverage reached the maximum value at 1.4% and the minimum value at 1.6%.

This may be due to the fact that hydroxypropyl octenyl succinate esterified starch, unlike other traditional edible modified starches, is a surfactant containing both lipophilic and hydrophilic groups, which can link the oil and water phases in the corn beverage system through the lipophilic groups of hydroxypropyl octenyl succinate modified starch.

Corn beverage is a kind of oil-in-water emulsion, adding hydroxypropyl octenyl succinate modified starch to corn beverage can play the role of emulsification and stabilization, so that the corn beverage system forms a uniform and stable dispersion or emulsion.

Therefore, the corn beverage has the best stability when 1.6% of hydroxypropyl octenyl succinate modified starch is added to the corn beverage.