Disodium succinate , abbreviated as WSA, commonly known as dried shellfishin, is a widely used fresh flavor agent in seasonings in recent years. It is more commonly found in seafood such as shellfish, shrimp and crab, and plays a very important role in the fresh flavor presented by such foods.

In addition, disodium succinate is also present in other plants, such as shiitake mushrooms. The hygienic standard of food additives in China stipulates that it can be applied in flavorings. In the past, China mainly relied on the import of disodium succinate from Japan and other countries, not only the long delivery period, but also the higher price, until 1998, China began to produce disodium succinate, the quality of which has reached the international standard, thus filling a gap in China’s food industry.

Introduction of disodium succinate

Disodium succinate is divided into crystalline disodium succinate and anhydrous disodium succinate. At present, the most commonly used in the food industry is crystalline disodium succinate, which usually contains 6 water of crystallization.

Disodium succinate is white crystalline particles or crystalline powder, odorless, acid-free, with special shellfish taste, taste threshold 0.03%, stable in air. Crystalline disodium succinate at 120 ℃ completely lose the water of crystallization, that is, anhydrous disodium succinate, anhydrous disodium succinate freshness is about 1.5 times as much as the crystalline disodium succinate.

Production of disodium succinate

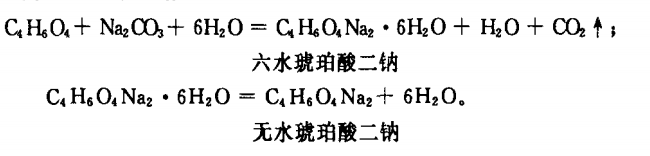

The production of disodium succinate is based on the principle of acid-base neutralization, which is achieved by neutralizing succinic acid with sodium hydroxide or sodium carbonate; the crystal disodium succinate loses its water of crystallization after being heated, i.e., it is anhydrous disodium succinate. The reaction equations of the two are as follows:

Domestic production process of disodium succinate: Preparation of solution of succinic acid, addition of sodium carbonate or sodium hydroxide, neutralization reaction, decontamination and filtration, concentration and crystallization, crystalline disodium succinate, drying, anhydrous disodium succinate.

Sodium carbonate is more often used as a raw material for the production of disodium succinate in China, while liquid sodium hydroxide is more often used as a raw material for the production of disodium succinate in Japan. Since the raw materials, especially sodium carbonate and liquid soda ash, will contain some impurities, it is necessary to carry out the work of removing impurities from the neutralized liquid. Crystallization is generally carried out by cooling in a crystallization tank.

Research on the application of disodium succinate in foodstuffs

3.1 Special shellfish flavor, the link of the harmonious transition of fresh taste

Different fresh flavor agents have different optimal action areas in the mouth, giving different fresh flavor sensations. MSG, I+ G and disodium succinate, which we usually use, have very different action zones in the mouth.

I+ G has a stronger sense of directness and precedence, the freshness is more monotonous, the freshness mainly acts on the front and sides of the tongue, its freshness functions before the sense of mid-perception; MSG’s freshness sensation acts on the back of the tongue, and the freshness gives a slower sensation when tasted. Another type of freshness agent is usually called compound freshness agent, such as HVP, HAP, YE, etc. The freshness sensation mainly acts on the sense of aftertaste and the sense of extension, and it is the main freshness agent that produces the aftertaste of food.

Disodium succinate in the oral cavity of the main receptor site is the middle of the tongue and the two palate, the fresh taste is mainly in the oral cavity in the middle of the presentation of the main body of the fresh taste of the food plays a very important role, is the first sense of the fresh taste of the food and the sense of the fresh taste of the sense of the aftertaste connected together with the fresh taste of the link, which enables the food flavor in the oral cavity to produce a harmonious transition to harmonize the flavors of all parts of the flavor, which is a very worthy of attention in the process of food flavor. This is a very noteworthy place in the process of food flavoring.

3.2 Research on combining with other fresh flavor agents to play the role of fresh flavor multiplication

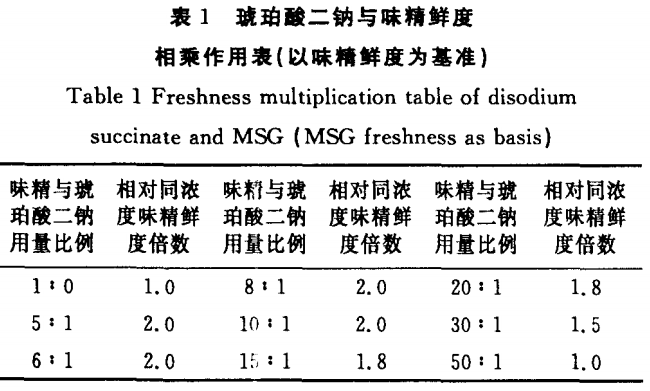

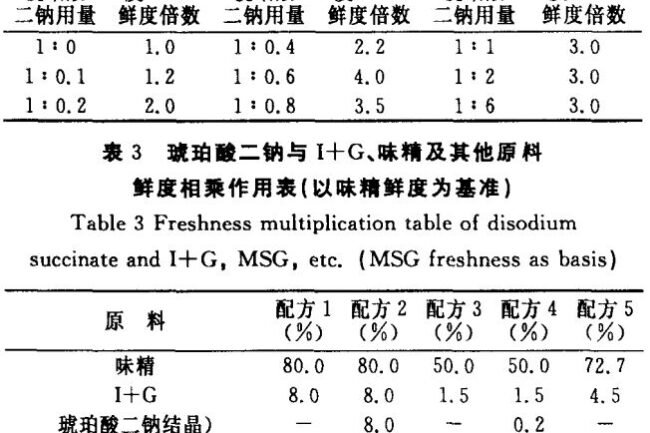

In addition to being used alone, disodium succinate is often mixed with MSG, I+G and other flavor enhancers in a certain proportion, so as to achieve the effect of flavor multiplication. Tables 1 to 3 show the synergistic freshness multiplication effect of crystalline disodium succinate with MSG and I+G.

From Table 1, it can be seen that when the ratio of MSG and WSA is mixed in the range of 5-10:1, the freshness multiplication reaches the maximum value, which can reach 2 times of MSG; from Table 2, it can be seen that when the ratio of I+G and WSA is mixed in the range of 1:0.6, the freshness multiplication reaches the maximum value, which can reach 4 times of I+G; from Table 3, it can be seen that when the disodium succinate is cooperated with MSG, I+G and other raw materials, the freshness can reach 8 times of MSG. The maximum freshness reached 8 times of MSG, comparing formulations 4 and 5, when reaching two times the freshness of MSG of the same concentration, formulation 4 using disodium succinate can significantly reduce the amount of MSG and I+G, thus reducing the cost.

3.3 Stability studies of disodium succinate in food processing

3.3.1 Heat resistance experiments

3.3.1.1 High-temperature heat resistance experiment (taking anhydrous disodium succinate as an example)

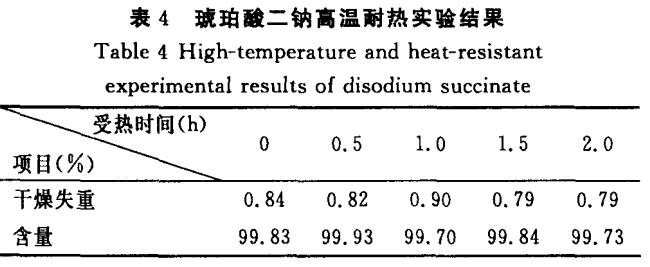

The samples were heated at 125℃ for 0.5, 1.0, 1.5 and 2.0h, and then the content and weight loss on drying were determined. The results of high-temperature heat resistance experiments of disodium succinate are shown in Table 4.

As can be seen from Table 4, the weight loss on drying and content of anhydrous disodium succinate were stable at 125℃ after being heated for 0.5, 1.0, 1.5 and 2.0h, respectively. Therefore, anhydrous disodium succinate can be used under high temperature food processing conditions.

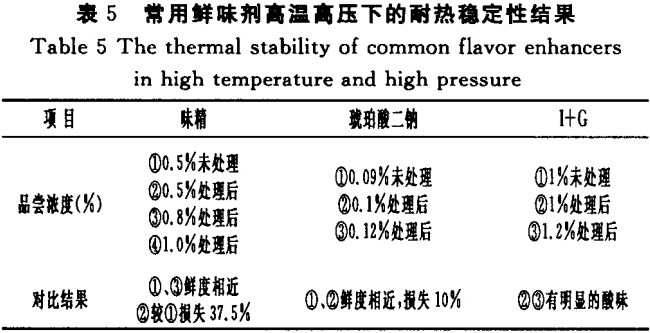

3.3.1.2 Heat resistance at high temperature and pressure

The 1% anhydrous disodium succinate, 1% I+G, and 1% MSG solutions were respectively applied at 121℃ and 1.2kg pressure for 1h. After processing, the solutions were diluted to a certain concentration and compared with the untreated samples for the freshness comparison, and the tasting results of the flavor changes of the three are shown in Table 5.

From Table 5, it can be seen that the loss rate of anhydrous disodium succinate under the above conditions is about 10%, while the loss rate of MSG is 37.5%, and there is also a significant denaturation of I+ G. This indicates that anhydrous disodium succinate is relatively stable at high temperature and pressure, because this experiment was carried out in solution, so the results are also applicable to crystalline disodium succinate.

3.3.2 Stability in acidic food application

Disodium succinate was added into Shanxi aged vinegar, Zhenjiang balsamic vinegar, 9-degree rice vinegar and 6-degree red wine vinegar at the ratio of 0.05%, and the flavor control was done with the unadded samples. The results showed that after adding disodium succinate, the acidity of the above vinegars was softer and more rounded, and the palatability was increased. After the products were placed for 2 months, the flavor of the products was stable, and there was no phenomenon of disodium succinate precipitation.

3.4 Preventing acidity and buffering salty taste of foodstuffs

Disodium succinate is the disodium salt of succinic acid, which is not volatile, and because it is a strong base and weak acid salt, it has a buffering effect in solution, so it can prevent food from souring, and it can also moderate the stimulation of other seasonings (e.g., salty taste) to produce a good taste.

Conclusion

After years of application and practice, disodium succinate has been widely used in China in the fields of meat products, aquatic products, sauces, vinegar and other household seasonings. The flavor characteristics of disodium succinate itself and its good synergistic effect with other food ingredients provide a broader field and prospect for its application in flavored foods.

In addition to its wide use in the food field, disodium succinate is also used in alcohol products in Japan, and in the pharmaceutical industry, it is also used as an anti-epileptic drug, therefore, disodium succinate has a very wide range of applications, which need to be further explored and experimented.