There are many kinds of raw materials used to make jam, the author takes banana as an example, briefly describes the production and processing technology of banana jam, and puts forward some ideas on the direction of product development in the combination of the two for the current application methods and status quo of jam in different dairy products.

Jam processing technology

1、Raw materials for jam production

Banana, belonging to the genus Plantago, is a perennial tree-like evergreen herb with sweet taste and cold nature, and has high medicinal value. The main function is to clear the stomach and intestines, cure constipation, and have the effect of clearing heat and moistening the lungs, quenching thirst, filling the essence, and relieving the poison of alcohol. Due to the cold nature of bananas, so the spleen and stomach cold, stomach pain, diarrhea should be eaten sparingly, excessive stomach acid is best not to eat.

Banana is high in nutrition, low in calories, and is a good nutritious food. According to the analysis, every 100g of banana pulp contains 20 g of carbohydrates, 1.23 g of protein, 0.66 g of fat, 0.9 g of crude fiber, 0.7 g of inorganic salts, 70% of water, and contains vitamin A (carotene), vitamin B1, vitamin B2, vitamin C, and vitamin U and other vitamins, and there are also minerals that the human body needs, such as calcium, phosphorus, and iron.

2, the production process of banana jam

Raw material selection, a pretreatment, a hot blanching, color protection, a pulping, a blending, filling, sealing, a sterilization, cooling, a finished product.

(1) Selection of raw materials

The raw materials are Hainan bananas which are full in appearance, fresh, free of pests and diseases, free of mechanical damage and ripened to 7~8%.

2)Pre-processing

a. Peeling

Peel the bananas and remove the black head from the top of the bananas and place them in a clean container for temporary storage.

b. Slicing

Cut banana segments of about 5 cm in length and remove bruised and rotten segments.

c. Washing

Wash in fresh water, about 50 times the mass of the banana, rinse and drain.

3) Blanching and color protection

Drain the bananas and immediately add them into boiling water and rinse them until slightly boiling, rinse them for 5 min and then drain them, pick out the black spots, add the color protectant (add sodium ascorbate according to 0.3% of the mass of bananas), mix well and stand by. In this process, the blanching time should be strictly controlled, and the test proves that blanching for 5 min can well passivate the activity of polyphenol oxidase, prevent browning, and also well preserve the flavor of bananas.

4) Pulping

Pass through 60 mesh colloid mill, quantify, refrigerate and reserve. If long time storage is needed, fill the banana after pulping, and sterilize it at 90℃/40 min, cool it with circulating water quickly and keep it in the refrigerator.

5) Blending

In order to maintain the refreshing flavor of jam, pectin and modified starch are often used as thickening agent, so that not only from the taste and water retention to achieve a better level. The conventional blending process is: ingredients, boiling and testing.

a. Dosing

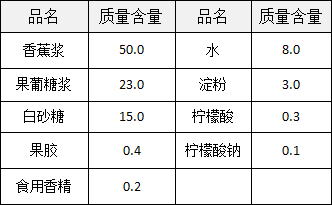

According to the optimization test of the proportion (Table 1) will be placed in the classification of each raw material, clearly identified.

b. Simmering

(1) Gum

The quantitative sugar and pectin mixed and dispersed in water, open the steam valve to heat to full boiling, keep warm for 3 min, until the glue is clarified and transparent. In this process, the sugar and pectin must be fully dispersed and dissolved in water, while the glue in the sandwich pot heating time should not be too long, more than 30 min will affect the viscosity of the glue.

(2) Heating concentration

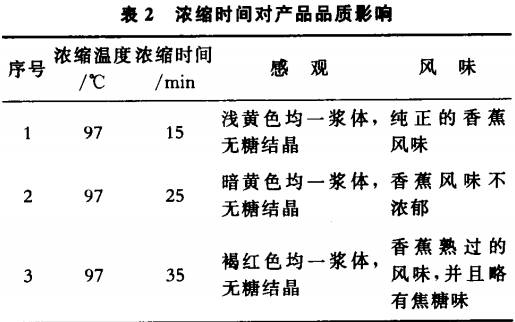

Sequentially, respectively, sugar, fructose syrup, fruit material into the sandwich pot heating, slightly boiling when adding good glue, concentration, concentration time directly affects the quality of the product.

(3) Starch dextrination Turn off the steam first, wait until the temperature in the pot drops below 80℃, then disperse the starch in 2 times the water, filter the starch solution through an 80-mesh sieve and add it slowly into the sandwich pot with constant stirring, so as to make the starch sufficiently dextrinate to viscosity. When casting auxiliary materials, citric acid needs to be added in preparation for the test, in the case of low acid will hydrolyze the starch, the viscosity of the system will be reduced.

c. Testing

According to the standard of the product for testing, the test samples taken need to be cooled to 20 ℃; after passing the test, add the flavor, stir for 2 min, and then hit the temporary storage barrel to be filled.

6) Filling and sealing

According to the specified specifications for hot filling, sealing for exhaust.

7)Killing and cooling

Sterilize the finished banana jam after filling, 90℃/30 min, cool it down to 25℃ after finishing and pack it into storage. Generally combined with dairy products jam sugar control in 30 ~ 40 degrees boomerang is appropriate.

Application of jam in dairy products

Currently on the market, almost only fermented milk and milk beverages in liquid dairy have added jam, which can not only increase the taste of dairy products, but also meet the needs of different consumers.

1、Fermented Milk

Divided into the current market stirred yogurt (i.e., ordinary yogurt), curdled yogurt (i.e., old yogurt), jam in the two applications are very different.

(1) Stirred yogurt is in the yogurt fermentation is completed and then the jam and yogurt stirring, stirring can be divided into packages refrigerated, the proportion of jam added to 7% ~ 9%, and jam sugar and acidity have strict control, the general control of sugar in the 30 ~ 40 degrees of boeuf, pH value of 3.2 ~ 3.6 appropriate, so that the combination of jam and yogurt, not only rich in taste, but also more comprehensive nutrition.

(2) The technical difficulty of adding jam to curdled yogurt is far greater than that of ordinary stirred yogurt.

For one thing, jam must be added before fermentation of yogurt and fermented together with yogurt, and the consistency of the leavening agent before fermentation is very low, so how to ensure that jam and leavening agent do not fuse with each other. If fused, it will cause the yogurt to curdle unevenly and not fine;

Secondly, the fruit contains a large number of organic acids and natural color, how to ensure that the pigment does not migrate during the fermentation process, the pigment is incorporated into the milk a lot leading to uneven color, affecting the normal sales, and organic acids make the protein around the pulp undergoes local denaturation, which also leads to unsatisfactory coagulation.

Therefore, the addition of jam in the curdled yogurt, especially fruit particles more complete, it is necessary to make the jam and yogurt in the gelatinization after layering. Then it is necessary to ensure that the jam and leavening agent in the fermentation before not fused, and to use the method of solidification of the color in the fruit to fix the color, do not bleed, so that will minimize the impact of the jam on the milk.

2、Milk-containing drinks

Milk-containing beverages can generally be divided into neutral-type milk beverages and acidic milk beverages, neutral milk beverages are mainly made of water, cow’s milk as the basic raw material, add other flavor auxiliaries, such as coffee, cocoa, fruit juices, etc., and then color and aroma made of drinking cow’s milk. The protein content of which is not less than 1.0% is called milk drink. Acidic milk beverages include fermented acidic milk beverages and blended acidic milk beverages.

The above traditional products are mainly fruit-flavored, due to the acidity of fruit juice milk drinks and flavor of the good perception of the pH range of 4.5 ~ 4.8, while the isoelectric point of the casein in milk pH value of 4.6 or so, if you add jam or puree when the casein that is, it will be the loss of homogeneous electric charge repulsive force and coagulation of the large molecules into the precipitation, which led to the product stratification.

In addition, due to the high milk fat content in milk, easy to fat uplift. This not only increases the technical difficulties of the dairy industry, but also raises the threshold of jam into the milk beverage, but the huge market potential still attracts this countless scholars to research. Therefore, the addition of jam fruit particles in dairy beverages should be small, the general particle size of 5 mm x 5 mm x 5 mm, so as to ensure that the taste, but also to facilitate the pipette precipitation, for the viscosity and pH value of the jam will also be strictly controlled, which not only makes our dairy beverages more diversified tastes, but also increases the nutrition and fun.

The development direction of the combination of jam and dairy products

With the improvement of living standard, people pay more and more attention to the health and safety of diet. The vast majority of people drink milk to supplement calcium intake, yogurt is a good natural source of calcium, every 100g of curdled yogurt contains about 120 mg of calcium; at the same time, it is rich in B vitamins, choline, etc., so the product has a strong market demand and competitive advantage.

In this context, the combination of jams made from highly nutritious and rare fruits with yogurt is gradually being recognized and accepted by consumers, and has given rise to a variety of new types of jam products, such as composite fruit jams, jams with fruits and grains, and jams with fruits and vegetables.

For exclusive groups of people (e.g. women, children, etc.), the research and development of jams with health care functions to match dairy products can meet the needs of different groups of people. Room temperature yogurt as a new force, will have unlimited space for development, dairy beverages from the traditional single flavoring began to change, the domestic development of the snow lotus fruit water chestnut composite milk drink and other similar products will be the whole industry to push the development of a healthier direction.

At the same time, cheese has a lot of room for development, 10 years ago, cheese is still very strange for Chinese people, and now in the supermarkets of big cities, a variety of cheese has begun to become an important product in the dairy products cabinet, China’s cheese market contains a huge business opportunity, however, China’s localized production of cheese with less than 0.2% of the country’s total milk, and in the more developed countries in the dairy industry, using milk In countries with more developed dairy industries, the utilization of milk sources is generally around 30% to 50%.

Data analysis of the nutritional value of cheese should be 10 times that of fresh milk, so cheese is the highest nutrition in the dairy industry, the best quality products, “milk gold”.

With the different needs of people, cheese by virtue of its own advantages will be accepted by more and more consumers, the taste will be diversified from the original single flavor changes, which will be a new application of jam in dairy products.