Flour, as the previous link in the process of noodle food, must meet the needs of noodle food. China has a long history and a large population, the eating habits and food structures of different regions are very complex, and there are thousands of food varieties.

In order to study the convenience and representative significance, we take steamed bread, noodles and dumplings, which account for about 80% of the noodle food, as the research object to analyze and explore. From the traditional eating habits, north of the Huaihe River staple food to noodles; south of the Huaihe River staple food to rice, and now there is a blend of conditions, the south eat noodles; the north eat more and more rice, the overall consumption of flour is basically the same.

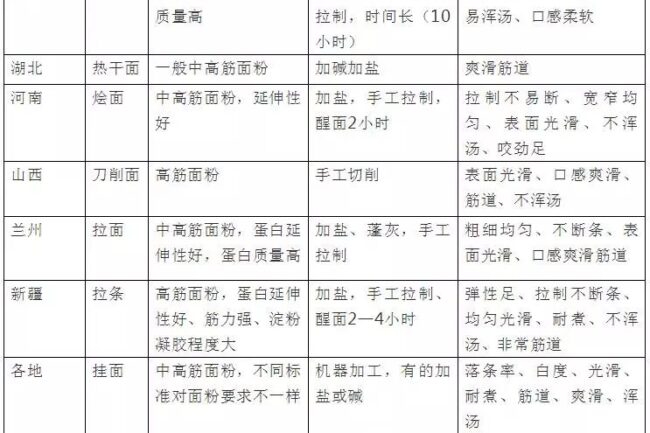

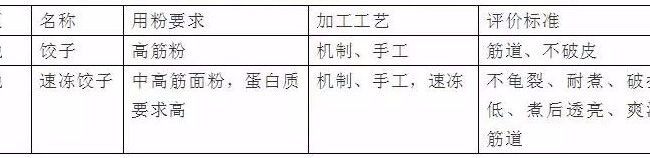

Although the south, the north eat are called steamed bread, noodles, dumplings, but due to the different eating habits of different regions, evaluation standards, processing technology is different, the quality of the flour requirements are also different, so as the flour must be adjusted according to the specific conditions of different regions.

For example, steamed bread:

From the above table, we can see that no matter it is steamed bread, dumplings, noodles, different regions have different processes and different evaluation standards. The special powder for steamed buns, special powder for dumplings and special powder for noodles on the market at present are all a kind of standardized production, which cannot be suitable for the processing requirements of noodle food in different regions.

And with the improvement of people’s living standards and the accelerated pace of life, industrialized production is bound to replace manual production as the mainstream. The requirements for the stability and specialization of flour quality will be stricter. To meet the requirements of different markets, we have to design specialized flour for different regions’ eating habits. So there should not be a unified standard of steamed bread, dumplings, noodles flour in China. Only multi-level, multi-species specialized flour can adapt to the market demand.

The influence of flour components on the quality of noodle products staple food

To produce a targeted multi-level, multi-variety special flour, we must figure out the requirements of different foods on the inner components of the flour, in other words, to be clear about which ingredients in the flour on which quality of food what effect?

After a large number of studies have shown that the components of the flour on the quality of the buns of the five major categories of substances: proteins, enzymes, starch, lipids, hemicellulose class.

The quality of steamed bread is a comprehensive reflection of the interaction of these five types of substances; and the processing of noodles, dumplings, cooking quality factors are mainly protein and starch. In the production process protein is the main influencing factor; and when cooking, starch directly affects the structure and taste of noodles. Because the elasticity and viscosity of cooked noodles and dumplings are 10-100 times higher than that of dough, however, the water content in noodles and dumplings is 400-500%, much higher than that of dough. It can be assumed that the protein content has a great influence on the mechanical properties of this system, but most of the physical and chemical properties of noodles and dumplings should be attributed to the pasting of starch rather than protein.

Relationship between the five components of flour and the quality of steamed buns

From the table, we can see the influence of various components in flour on the quality of steamed bread, noodles and dumplings. In this way, when producing various specialties, we can find the best combination of various components corresponding to the requirements of food quality. But at present the most common way to produce specialized flour is to match wheat and flour, although it can make the quality of flour adaptability improved, but can not solve the problem of specialization of specialized flour.

Problems in the current production of specialized flour

First: too many varieties of wheat is too heterogeneous, on the one hand, although to provide us with a large number of samples to choose from, but due to the variety of varieties, miscellaneous, the amount of each sample is small, quality is not stable, it is difficult to enter these data into the database for the production of the basis.

Secondly, the quality of wheat is unstable: 1) Due to the large latitude span in China, the quality of the same variety planted in different areas is not the same. 2) Our agricultural policy makes it difficult to form a unified state of planting on a large area. 3) It is difficult to achieve uniformity in seed and field management. 4) The weather directly affects the quality of wheat when harvesting. 5) It is difficult to achieve the quality of the current storage conditions, and the varieties are stored separately. The quality of wheat used in flour milling is very unstable, and it is difficult to grasp its quality changes.

Third: each kind of wheat, each kind of flour is an organic complex, not a single component, from the previous analysis, each kind of food should have its own internal components of the best combination of wheat in the distribution, distribution of flour, in order to increase a certain component, at the same time, will cause changes in the other components, with wheat, distribution of flour can only be formed to meet the requirements of a basic flour.

Fourth: a wheat is an organism, a variety of wheat flour mixed together is difficult to form an organic whole.

So to produce multi-level, multi-species special flour to meet the requirements of different regions, rely on wheat, with powder is not a solution to the problem, we can use multi-disciplinary high-tech to solve this problem.

Natural and class natural improver on the role of flour components

Above we have analyzed the flour components that affect the quality of food, and each of them we can use biological, emulsifier and other technologies to make it transformed in the direction we need, so that it is close to the best combination of components, or the best performance of the finished product. And all the products we use must meet the needs of the food industry as it develops, i.e. safety and efficiency. That is why we must use natural or natural-like products. There are five main categories of components that we can modify on a case-by-case basis to approach or meet the needs of the food product.

1) Proteins: we can use emulsifiers to connect wheat gluten and wheat gliadin to form a more complete gluten network, oxidizers such as VC to turn -SH into -S-S-; cysteine proteins to connect low-molecular-weight gluten; transglutaminase to cross-link proteins Transglutaminase cross-links proteins; protease breaks down proteins.

2) Starch: α-, β-amylase breaks down starch; emulsifiers, phytocolloids complex starch, emulsifiers, sugar, oils and fats change the pasting properties of starch.

3) Enzymes: add α-, β-amylase or pentosanase, protease to increase its activity, can also add β-cyclodextrin and other inhibitors to inhibit its activity.

(4) Lipids: add emulsifiers of polar lipids to increase the content of polar lipids, or use lipase to turn non-polar lipids into polar lipids.

( 5) hemicellulose: more research is pentosan, can add pentosan to increase its content, can also add pentosan enzyme to reduce its content.

In summary, only in the food requirements, wheat and flour quality and other aspects of a comprehensive understanding of the basis for a reasonable allocation of wheat, flour, and then through the targeted post-processing improvement technology can produce a variety of special powders to meet the needs of different foods, but to do a good job of this systematic project, we must focus on the height of the wheat industry chain, increase scientific research investment in this interdisciplinary research field, in-depth and detailed to do! A lot of basic research work to break through the limitations of the traditional improvement technology.