Tablets are solid preparations with dense structure formed by the action of tablet press on one or several kinds of powders. With different shapes, beautiful appearance, accurate dosage, taking aspect, multiple routes of administration, which can meet different clinical needs, it is one of the most important dosage forms in modern solid preparations.

The compression characteristics of pressed tablet materials are usually a combination of multiple compression and deformation mechanisms and multiple powder chemical properties. The compression characteristics and fluidity of tabletting materials directly affect their adaptability to high-speed tabletting in production, and the ideal tabletting materials should have excellent fluidity and compressibility.

Types of tablets include: oral tablets, chewable tablets, effervescent tablets, oral tablets, orally disintegrating tablets; general raw materials and auxiliary materials include: active ingredients, fillers, lubricants, sweeteners, colors, flavors, stabilizers, effervescent agents, disintegrating agents.

Problems that often occur in pressurized candies

Flavor

1、The selection principle of flavor

– Recommendation: use oil-soluble liquid flavor, flavor presentation is better than powder flavor, you can also use powder flavor

– Recommended: IFF, Chihuateng, Fenmei Yi

– Prohibit: water-soluble flavors

2、Frequently Problems

– Water-soluble flavors are caked and hardened. The taste is slightly rough, the flavor is not natural.

– Worry about the oil-soluble liquid flavor can not be mixed, do not dare to use, so the taste can not reach the state of competitors.

Pressure tablet candy often prone to problems

Lubricant (magnesium stearate, etc.)

1, the use of lubricants principle

– Must: Magnesium stearate and other lubricants need to be added now;

– Must: magnesium stearate needs to be added at the final stage of mixing;

– Suggestion: the typical adding amount of magnesium stearate is 0.8%, less than 0.5% or too much lubricating effect is reduced;

– Suggestion: in some special tablets (solid beverage standard effervescent tablets, need to consider dissolvable lubricant sucrose ester, etc.)

2. Frequently Asked Questions

– Do not allow the material mixed into magnesium stearate to be pressed overnight or delayed for a longer period of time, this will greatly affect the compressibility.

– Do not add magnesium stearate, or add more than 2% magnesium stearate.

Problems that often occur with pressed tablets

Tabletting environment

1、Relative humidity

– For sorbitol, xylitol and other materials that are easy to absorb moisture, the humidity of the experimental and production environment should be controlled within 40%, while other materials such as maltitol can be relaxed to 50%;

2、Environmental temperature

– Tabletting environment temperature should be controlled within 25 degrees.

3、How to improve the environmental humidity and temperature

– Dehumidification equipment (independent industrial dehumidifier, preferably equipped with tabletting workshop)

– Air conditioning system

– Select dry weather and low temperature season to stagger production.

– Adopting materials that are resistant to moisture absorption

Problems that often occur in pressed confectionery

Color

1、Recommended aluminum color precipitate

– Aluminum color precipitate has the characteristic of uniform coloring, and the overall color of tablets is transparent. It is more stable with respect to environmental temperature, humidity, oxygen and other factors.

– Suggested source: Shanghai Dyestuff Research Institute Co.

2、Frequently Problems

– Adopting some other types of powder pigments, there are poor mixing effect, spots and uneven coloring;

– VC and other materials that are easy to oxidize and change color, originally have no color, the color is abnormal after preservation or accelerated experiments, and need to add some approximate color to cover it up

– Some materials itself is very dark color, easy to cause significant spots, we generally recommend the use of finer maltitol or the use of further granulation process.

Pressure tablet candy is often easy to appear detour

Formulation design

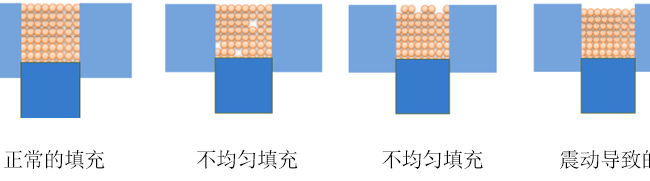

1、Excipient selection of the examination factors

– Moisture absorption → Consider materials that resist moisture absorption

– Oxidation resistance, heat sensitivity, light sensitivity → consider coating, reducing agent and other measures

– Granularity, fluidity, ease of mixing, dosage per tablet, coloring uniformity, taste, tablet weight stability.

– Effective dosage of functional materials → design of tablet weight, frequency of administration

– Taste, flavor, and color of functional materials → flavor, acid, pigment, coating, etc.

2、Frequently Problems

For some very fine granularity of the material 200-400 mesh, usually poor compression, the proportion of auxiliary additives need to be increased;

– Good mobility is the key to reducing the above problems

—- Angle of repose

—-Hausner Ratio

– More advanced instruments are powder flow testers