What is the production and application of maltose and maltitol?

Maltose, relative molecular weight: 360. The root maltose content is divided into malt sugar, high malt syrup and ultra high malt syrup. The traditional method of making maltose is to use the grain containing starch by malting enzyme, so it is called maltose, commonly known as sugar melon, sugar dilute.

As early as 1500 years ago, there was the production of maltose in China. Maltose is mostly transparent viscous liquid, but also condensed and cooled crystallized into solid, it is one of the low calorific value and low sweetness sugars with great prospects for development, and its sweetness is equivalent to 30% to 40% of sucrose, and its calorific value is only 5% of sucrose. Maltitol can be prepared by oxidizing maltose.

Maltitol, relative molecular weight 344, pure maltitol is colorless transparent crystal, is a sweetener with the same sweetness as sucrose in a low thermal region. Maltitol’s low calories, lack of tooth decay, good taste and high sweetness compared to most other sugar alcohols make it widely used.

At present, people’s health requirements for low calorie and low fat products are getting higher and higher, and the development prospect of maltitol industry is getting better and better. The present production technology and application of maltose and maltitol were discussed in this paper.

Production technology of maltose

1. The production process of maltose starch – gelatinization – acid liquefaction (enzyme liquefaction) – saccharification – decolorization – ion exchange – concentration – finished product

1) Ultra-high malt syrup production process Ultra-high malt syrup maltose content of more than 70%, including fermentable sugar content of more than 80%, the use of ultra-high malt syrup is different from the general malt syrup, the use of ultra-high malt syrup is mainly used for the manufacture of pure maltose, it is dried to produce maltose powder, it is hydrogenated to produce maltitol.

The production of ultra-high malt syrup must be accompanied by debranch enzyme, and the degree of liquefaction should be strictly controlled, the DE value should not exceed 10%, due to the high viscosity, so the substrate concentration should not be too high, generally controlled below 30%, especially when the production of ultra-high malt syrup with maltose content of more than 90%, the DE value of the liquefied liquid should be below 1%.

2) Using β-amylase and debranching enzyme saccharification methods, with starch liquefaction solution with 30% solid concentration and 8% DE value as substrate, adding different amounts of β-amylase, branchchain amylase and isoamylase, hydrolyzing at 50℃ for different time, can significantly promote the formation of maltose.

1) Crystallization method The crystallization of maltose is closely related to supersaturation, the solubility of pure maltose is smaller than sucrose and glucose at room temperature, and at 90℃ ~ 100℃, it is much larger than the above two kinds of sugar, up to 90%, the purity of 94% malt syrup concentrated to 70% concentration. Add the seed according to the dry matter of 0.1% ~ 0.3%, gradually cool from 40℃ ~ 50℃ to 30℃ ~ 27℃, maintain the susaturation of 1.15 ~ 1.30, slow cooling, 40h crystallization is completed, the yield is about 60%, the purity is above 97%, the mother liquor can be reused, the waste molasses can be dried to make whole sugar powder.

2) Adsorption method (1) Activated carbon adsorption method of various sugar molecules in syrup first adsorbed on activated carbon, with increasing alcohol concentration of various sugars washed in turn, so as to achieve the purpose of separation. The activated carbon is also loaded with solvent, and the oligosaccharides above maltose are adsorbed on the column through syrup to obtain high-purity maltose. Different activated carbons have different adsorption capacity to dextrin and oligosaccharides. Two activated carbons were properly combined to adsorb dextrin and oligosaccharides to obtain pure maltose.

② Ion exchange method Anion exchange resin DowexZ, Amberlite RA41l, etc., can adsorb maltose and maltose triose in sugar solution, wash maltose with water and 2% hydrochloric acid, the yield can reach 100g/L resin, purity 97%.

(3) The solvent precipitation method will cool the syrup to 20℃ below, adding acetone 30% ~ 40% (W/W) can get 95% ~ 98% purity of maltose, yield more than 50%.

The method of separating various sugars by membrane filtration has been proposed very early, and with the development of membrane technology, maltose with a purity of more than 96% can be obtained by using ultrafiltration and reverse osmosis.

Production technology of maltitol

Sugar alcohol products can be obtained by hydrogenation of corresponding sugars, such as xylose hydrogenation to xylitol, glucose hydrogenation to sorbitol, fructose hydrogenation to mannitol, maltose hydrogenation to maltitol, and the production process is also similar. The raw materials for the production of maltitol can be purchased from the market or produced by oneself, and the production process is as follows:

Maltose – pH adjustment – hydrogenation – filtration decolorization – ion exchange – evaporation concentration – crystallization – finished product

Dilute the malt syrup to about 50% and adjust the pH with NaOH to 7.5-8. The adjusted syrup enters the hydrogenation reactor for hydrogenation, the catalyst used is skeleton nickel, powder (Ni, Al, Mo) for intermittent reaction, block for continuous reaction, the dosage is 10% ~ 12%. Control reaction pressure 7.5MPa ~ 8MPa, reaction temperature 115℃ ~ 125℃. The hydrogenated liquid is filtered first, on the one hand to filter out impurities, on the other hand to remove the pigment in the hydrogenated liquid, and then the ion exchange is carried out, the main purpose is to remove metal ions, and finally under negative pressure. Use a scraper or film evaporator to concentrate to a dry content of more than 70% of the finished product.

Maltitol is available in liquid and crystalline form. Because crystal maltitol products are convenient to transport, high purity, can be directly added in food and other industries, safe and reliable, the market sales are far more than liquid products. However, in the current production process of crystalline maltitol, the requirement of raw material maltose is higher. As the raw material of maltitol, the content of maltitol should reach more than 60%, otherwise the total alcohol after hydrogenation maltitol can not reach 50%, it can not be called maltitol.

The higher the purity of maltose, the higher the purity of maltitol after hydrogenation. When the purity of maltitol is about 90%, the crystallization process can proceed smoothly. This requires the purity of raw maltose to reach more than 90%, and with the current production process of maltose, to obtain high-purity maltose, the cost is bound to increase significantly. The three-way separation method of SSMB can effectively solve this problem.

The starch was converted by the combination enzyme of common α-amylase, β-amylase and Pululanase to produce maltitol with a purity of more than 75%, and the maltitol with a purity of 75% was obtained by hydrogenation of the maltitol. The maltitol was separated by SSMB sequential simulated moving bed, and three components of sorbitol, other miscellaneous alcohols and maltitol with a purity of more than 95% were obtained. Crystal maltitol can be obtained after concentration, crystallization and centrifugation of maltitol with purity above 95%.

Application of maltose and maltitol

1, the application of maltose malt syrup is widely used in various fields of the food industry, solid food, liquid food, frozen food, colloidal food (if frozen) and so on. Malt syrup is not only a sweetener in food, but also an additive, fresh-keeping agent and moisturizing agent. Malt syrup contains a lot of dextrin, has good resistance to crystallization, there will be no crystal precipitation in frozen food, and prevent the crystallization of other sugars, so that you can prevent the crystallization of sucrose in the production of jam and jelly, extend the shelf life of food.

Malt syrup has good fermentability, so it is also widely used in the manufacture of bread, pastries and beer. Malt syrup prevents starch condensation and aging, and can increase the shelf life of jellies, jams and starchy cans. Malt syrup has low sweetness, low moisture absorption and high moisture retention. Maltose with one molecule of crystal water is very stable, which increases the moisture retention of food.

The addition of malt syrup in the pastry can make the pastry fresh and delicious, but when the maltose absorbs 6% to 12% of the water, it no longer absorbs water, nor does it release water, which can make the food dehydrate and prevent the aging of the food, so that the food is soft, moist, fresh and delicious for a long time, and increase the shelf life of the food.

Maltose is relatively stable to acid and heat, and is almost not decomposed at pH=3 and 120℃ for 90min, and the sugar boiling temperature can reach 160℃, so it will not cause food deterioration and taste deterioration due to the decomposition of maltose at room temperature.

High malt syrup can replace acid-hydrolyzed starch syrup in the confectionery industry, not only mild taste, moderate sweetness, the product is not easy to change color, and hard sugar has good transparency, has good sand resistance and durability, so as to extend the shelf life. The high malt syrup has good thermal stability and is more suitable for sugar making and casting by vacuum film method than malt sugar.

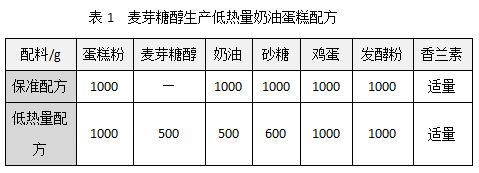

1) The application of maltitol in functional foods Maltitol is almost not decomposed in the body, so it can be used as a food raw material for diabetic patients and obese patients. The recipe of low-calorie cream cake is shown in Table 1:

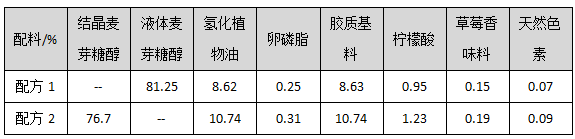

2) For candy, chocolate production due to the good flavor and taste of maltitol, with good moisture and non-crystallization, can be used to make a variety of candy, including foam marshmallow, hard candy, transparent fudge and so on. An example of maltitol confectionery recipe is shown in Table 2:

3) Application in fruit juice drinks Maltitol has a certain viscosity and is difficult to ferment, so when manufacturing suspended fruit juice drinks or lactic acid drinks, adding maltitol to replace part of the sugar can make the drink taste full and lubricious.

4) The application of maltitol in frozen food ice cream can make the product delicate and thick, sweet and delicious, and extend the shelf life. As a food additive, maltitol is allowed to be used in cold drinks, pastries, fruit juices, biscuits, breads, pickles and candies, and the amount can be determined according to production needs.

Market and development prospect of maltose and maltitol

Maltose and maltitol have been developed for many years, but due to the consumption habits and consumption level of our people, the industrial production started late, far from meeting the market demand, but the development trend has been formed. Judging from the consumption structure of maltose and maltitol, most of them are used for food and functional food. Most of the products are sold domestically, and there are exports, and the export volume is on the rise.

Maltose and maltitol is an important food additive and sweetener, because of its unique physiological function and anti-caries effect, is the sweetener of special food for diabetes patients, and plays the role of nutrition and adjuvant therapeutic agents for diabetes patients, with the development of China’s economy and the improvement of people’s living standards, people’s life gradually from a full diet to nutrition, health care transformation. It is natural that maltose and maltitol come into people’s life. There are nearly 30 million diabetic patients in China, and the demand for maltitol and maltitol is quite considerable. There are nearly 400 million children in China, and children’s special food and health food have developed rapidly, which are potential markets for the development of maltose and maltitol, and also provide opportunities for the development of maltose and maltitol.

At the same time, with the continuous improvement of Chinese people’s living standards and the continuous change of food structure, maltol and maltol, as sugar substitutes, will certainly occupy a place in China’s food industry. As a big agricultural country, starch raw materials are sufficient, which provides unique conditions for the production of maltose and maltitol, and China’s maltose and maltitol industry will have greater development.