What is Red Yeast of Food Additives?

Red Currant

National Standard: GB 1886.181-2016 National Standard for Food Safety Food Additives Red Yeast Red

Definition: A food additive obtained by extracting, concentrating and refining the liquid medium of rice and soybean as the main raw material and the liquid fermentation culture, extraction, concentration and refining of Monascus; or by extracting, concentrating and refining the food additive obtained by using red currant rice as the raw material.

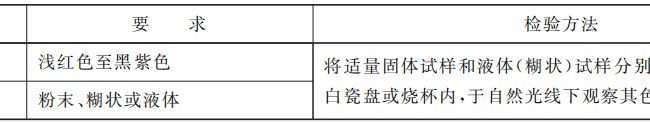

Sensory requirements:

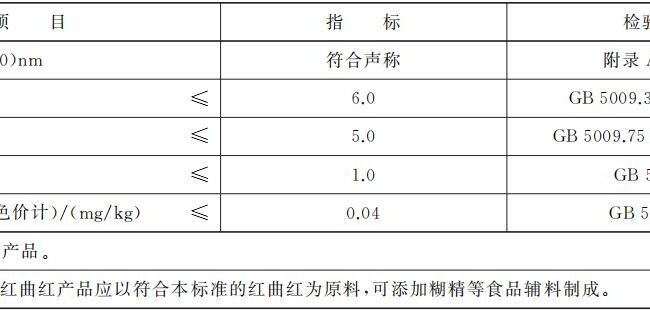

Physical and chemical indicators:

Solubility: Soluble in neutral and alkaline aqueous solutions. In the medium below pH4.0, the solubility decreases. Easily soluble in ethanol, propylene glycol, propanetriol and their aqueous solutions, insoluble in grease and non-polar solvents.

Stability: heat resistance and acid resistance, direct sunlight can fade. It has strong coloring performance on protein, once stained, the color will not fade even after washing.

Application of red crimson pigment in products

The application of fermented sausage in meat products is through the inoculation of lactic acid bacteria for fermentation and made of meat products, in the traditional processing methods, adding nitrite coloring, but taking into account the potential hazards of nitrite, a researcher switched to red pigment for fermented sausage coloring agent, the results show that: 1600 ppm of red pigment as a coloring agent for the production of the color of fermented sausage is close to the color of the fermented sausage of 150 ppm sodium nitrite as a coloring agent, the color of the fermented sausage is similar to that of the color of the fermented sausage of 150 ppm sodium nitrite. The results showed that: the color of fermented sausage made with 1600ppm red yeast pigment as coloring agent was close to that of fermented sausage made with 150ppm sodium nitrite as coloring agent; the fermented sausage made with red yeast pigment was not discolored within one month when stored at 4℃. Although the dosage is more than that of sodium nitrite, the safety is high.

At the same time using 1600mg/kg of red currant pigment mixed with Streptococcus lactis or potassium sorbate, found that Clostridium botulinum has a significant “poisonous” effect, so that the nutrient cell rupture. That is to say, the use of red pigment as a coloring agent, can replace part of the amount of nitrite, but also inhibit Clostridium botulinum bacillus.

Application in tofu milk tofu milk is China’s traditional fermented food, tofu after fermentation, protein hydrolysis into a variety of amino acids as well as alcohols, esters, organic acids, aromatic presenting substances, the formation of tofu milk unique color and aroma style, and nutrient-rich, in order to be absorbed.

Red Bean Curd uses red curd pigment to form an attractive red color on the surface of the product and a variety of aroma and flavor components inside. Its production process is as follows:

Soybeans → soaking in water → grinding → filtering → boiling → spotting (adding coagulant) → raising flowers → pressing → blocking → curd billet → inoculation (Trichoderma or Rhizoctonia) cultivating bacteria → pickling billet (adding salt) → mounting altar [adding ingredients (yellow wine or rice wine + noodle curd + red curd red powder + flavorings)] → maturing → finished product

In the application of soy sauce will be added directly to the red currant pigment powder in the fermentation of soy sauce spirits, can improve the red index of soy sauce, and improve the flavor of soy sauce.

Application in confectionery In the production of confectionery, when adding red currant water extract, the different amount of its addition to the aroma, taste and texture of red currant bread does not have a great impact, only with the increase in the amount of addition, the color has deepened and become red. Compared with the direct addition of red currant powder, there is a big change in all aspects, especially in the aroma, compared with the pastries made without red currant extract, it is more refreshing and unique. The reason of red color fading

1、Temperature red yeast red pigment is relatively stable below 130 ℃, when the temperature is higher than 150 ℃ or more, the red yeast red pigment begins to rapidly denaturation decomposition, resulting in rapid loss of color.

2, light Research has found that continuous light will significantly reduce the stability of erythrocyanidin red pigment. Red vein red pigment is relatively sensitive to sunlight, and will undergo significant discoloration under sunlight irradiation. In the same light intensity, as the wavelength decreases, the degree of degradation of erythrocyanine red pigment rises, especially sensitive to ultraviolet light.

3, metal ions research found that a small amount of sodium ions, calcium ions on the reddish red pigment almost no effect, while zinc ions, copper ions on the reddish red pigment has a significant impact. Among them, Cu2+ and Fe3+ will make the reddish red pigment bright red to brown, and produce precipitation.

4, additives or other agents experiments found that the erythrocyanine pigment on sodium nitrite, ascorbic acid, hydrogen peroxide and other additives and reagents, but in the presence of sodium hypochlorite, the erythrocyanine pigment faded seriously.

5, Oxygen erythrocyanine pigment has a strong scavenging capacity of free radicals, with significant antioxidant properties. Oxidation will change the color of erythrocyanidin.

6、pH red pigment is relatively stable in the range of pH3~10, higher or lower than the range, the stability of red pigment decreases significantly.

Preventing red color fading measures

1、Control the thermal processing temperature, for the frying process, can be changed to low temperature frying. 2、Avoid light, using light insulation measures. 3、Add metal chelating agent, such as disodium EDTA. 4、Add antioxidant, such as ascorbic acid, citric acid, etc. 5、Replace the packaging materials, the use of light barrier and oxygen barrier performance of the package material is better. 6、Pay attention to the amount of disinfecting reagents in the production environment and the amount of residue