What is the corn starch production process?

Corn is stripped from the corn kernels on the ears of corn, and the corn kernels contain 12~16% moisture, 70~72% starch, 8~11% protein, 4~6% fat, 1.2~1.6% ash, and 5~7% fiber.

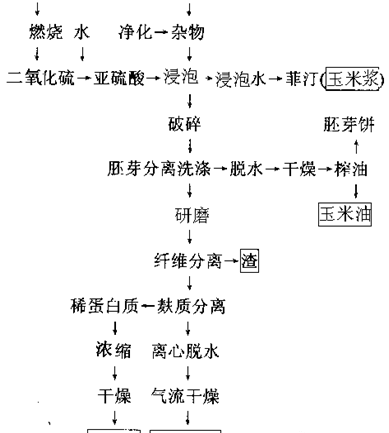

Corn starch is a product made from corn kernel as raw material, through sulfite soaking, crushing and sieving, grinding, separating and washing, dehydration and drying.

The product is mainly used in medicine, food, chemical industry, textile and other industries, can produce caramel, high maltose syrup, glucose, modified starch, soluble starch, cyclodextrin, acidic starch, oxidized starch, high fructose syrup; can be used as raw materials for the production of enzyme preparations, monosodium glutamate, amino acids, and antibiotics, such as the raw material for fermentation.

In recent years, with the development of production in all walks of life, corn starch with a wide range of uses, excellent performance, moderate price to the market, doubly favored by the market.

Corn starch production process

Operation Points

2.1 Selection of raw materials, choose to remove impurities, full grains, no insects, no moldy corn as raw materials.

2.2 Preparation of sulfurous acid by burning sulfur to prepare sulfur dioxide, and then dissolved in water to prepare sulfurous acid, the newly prepared sulfurous acid solution containing S02 0.25~0.3%.

2.3 Corn soaking and crushing using countercurrent method or diffusion method of soaking, will be newly prepared sulfite solution pumped into a group of soaking tanks to soak corn, according to the soaking liquid countercurrent pouring tanks way, the longest soaking time, in turn, to the shorter soaking time to move (inverted tanks), with this method, the concentration of leachate can be up to 7-9%, leachate further concentration of the steam consumed less than the stationary method.

After soaking corn using the second crushing, separation process, so that all the germ from the endosperm separated from the endosperm. Soaked corn germ contains about 60% water, has great elasticity, at the same time the germ, corn husk and endosperm linkage between the weakening of the endosperm protein and starch in the corn endosperm weakened, easy to separate from the corn kernel when crushed. In addition, the amylopectin portion of the endosperm is ground into crushed grains during crushing, from which about 25% of the starch can be released.

2.4 Separation and washing of germ Corn kernel after primary crushing, most of the germ and endosperm are separated, and the germ is separated through floating tank, then into the secondary crushing, after two crushing and separation, the germ is all separated. The separated germ is sprayed by continuous water on the vibrating screen to wash away the adhered starch milk and gluten on the surface of the germ, and then it is preliminarily dewatered by centrifuge to the moisture content less than 36%.

2.5 Grinding of slurry After crushing and separating the endosperm, the crushed slurry consisting of starch granules, gluten, seed coat, crushed endosperm grains containing a large amount of starch, etc., needs to be finely ground by primary and secondary impact mills with the aim of making the endosperm finer in particle size and at the same time releasing the starch associated with proteins and cellulose at the maximum extent, so as to create conditions for the separation of the next step of the process.

2.6 Sieving and washing of dregs The suspension formed after pulp grinding contains free starch, fine particles of gluten and cellulose (fine and coarse dregs). Separation of the coarse and fine dregs from the starch suspension is carried out using a seven-stage pressure curved sieve, and the dregs are washed in six countercurrent stages to wash the starch adhering to them.

2.7 Separation of starch and gluten Separation of starch and gluten is carried out in disc centrifuge. Since the particle size and specific gravity of starch particles are larger than that of protein particles, its settling speed in suspension is faster than that of protein particles, so starch and protein can be separated efficiently with centrifugal separator.

2.8 Washing and mechanical dehydration of starch In order to remove soluble and insoluble proteins, reduce the acidity of starch and improve the concentration of suspension, ten-stage cyclone countercurrent washing is used. After washing, the starch is mechanically dehydrated by horizontal scraper centrifuge, and the water content of wet starch is 38~40%.

2.9 Drying of starch Adopting airflow drying, the starch is fed into the fluffer by the screw conveyor according to the requirement of output (depending on the moisture content of the finished starch), and the mechanically dehydrated wet starch will be fed into the airflow drying system in the fluffer, and at the same time, the pre-purified and heated hot air up to 140 ℃ is fed in to carry out the drying.

Production of by-products

3.1 The production of corn oil washed germ by centrifugal dehydration, in the rotary drum dryer with a heating furnace, baking and drying to the moisture content of 1 ~ 1.5%, with a screw press press, press out of the oil storage tank, so that the oil in the suspended impurities in the natural precipitation, filtered by the plate and frame filter press to remove impurities, to get the wool of corn oil, which contains more than 85% of unsaturated fat corn oil. Corn oil can also be further processed into margarine, shortening and so on.

3.2 Protein powder production from the butterfly centrifuge separated from the yellow pulp, sent to the storage tank in the natural settlement, pumping up the supernatant, 5% concentration of yellow pulp filtered by the plate and frame filter press to the non-dripping, the cake will be sent to the pulverizer in the crushing, and then into the air dryer to dry to less than 14% moisture content can be.

3.3 The production of leachate (corn syrup) in the process of corn soaking, soluble dry matter from the corn kernel transferred to the leaching solution, with the diffusion method of leaching in the leachate dry matter content of up to 8 ~ 9.5%, leachate contains a large number of proteins, soluble carbohydrates, ash, oil, starch, lactic acid and other substances. The leachate is concentrated to 48~50% of dry matter by vacuum concentration method, and corn syrup is obtained, and the by-product can be used to produce antibiotics, yeast and alcohol.

Corn starch product quality standard and production test results

Production test on corn starch products, the results are shown in the table below, the average flour yield of 59.8%.

Conclusion

Using this process for production test, the average starch rate is 59.8%, and the product quality reaches the standard of superior grade. This process not only produces the main product corn starch, but also produces three kinds of by-products, which can improve the utilization rate of raw materials, reduce energy consumption and environmental pollution, lower production costs, and achieve the purpose of comprehensive utilization.